Screen printing system for composite nameplate

A technology of screen printing and nameplate, which is applied in the direction of screen printing machine, printing, printing machine, etc., can solve the problems of low processing efficiency, difficult nameplate positioning, manual loading, etc., to improve accuracy and work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

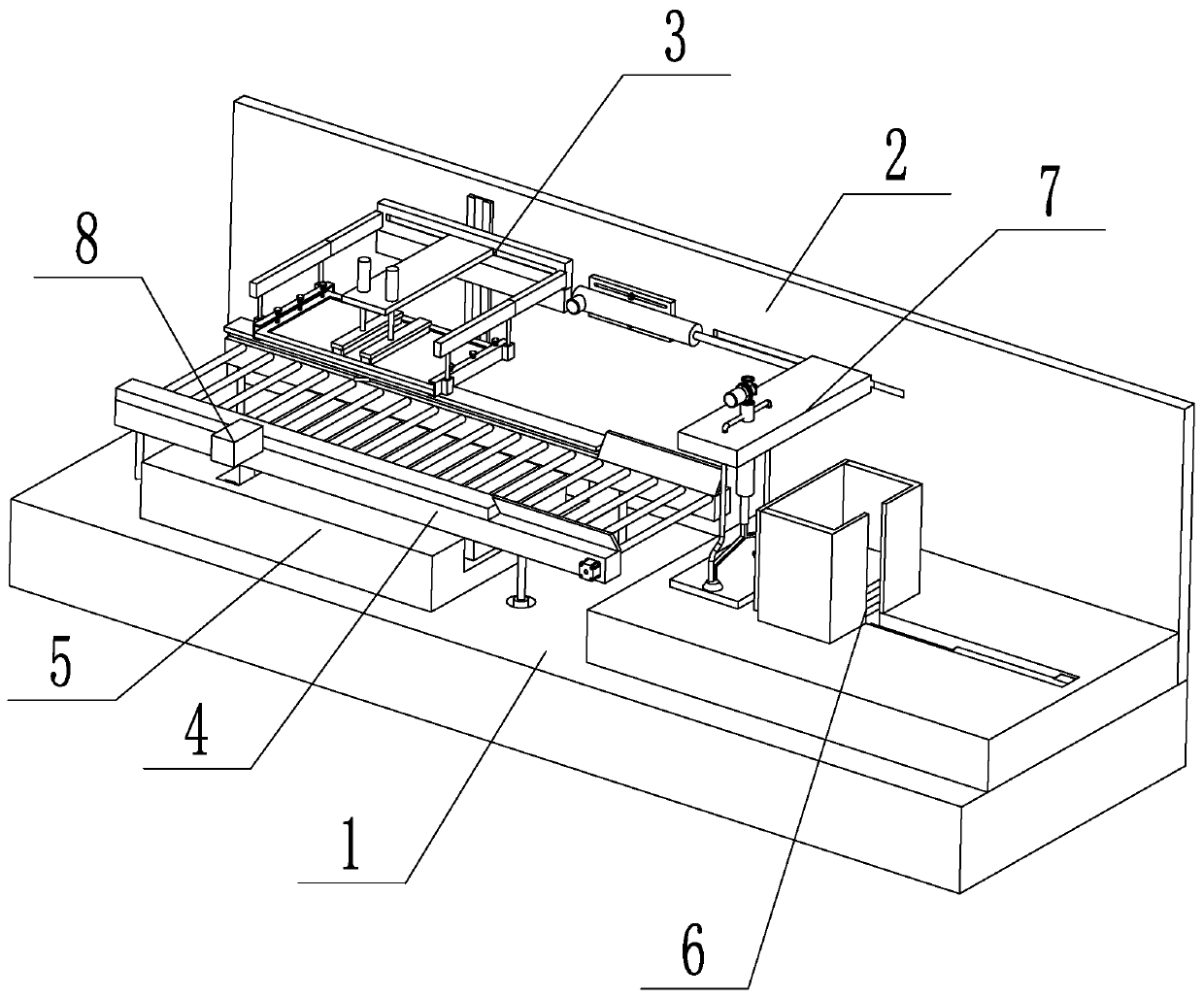

[0036] refer to figure 1 , is a composite nameplate screen printing system disclosed in the present invention, including a frame, a workbench 1 horizontally arranged on the frame, a printing mechanism 3 arranged on the frame, a feeding mechanism and a transfer mechanism 7 .

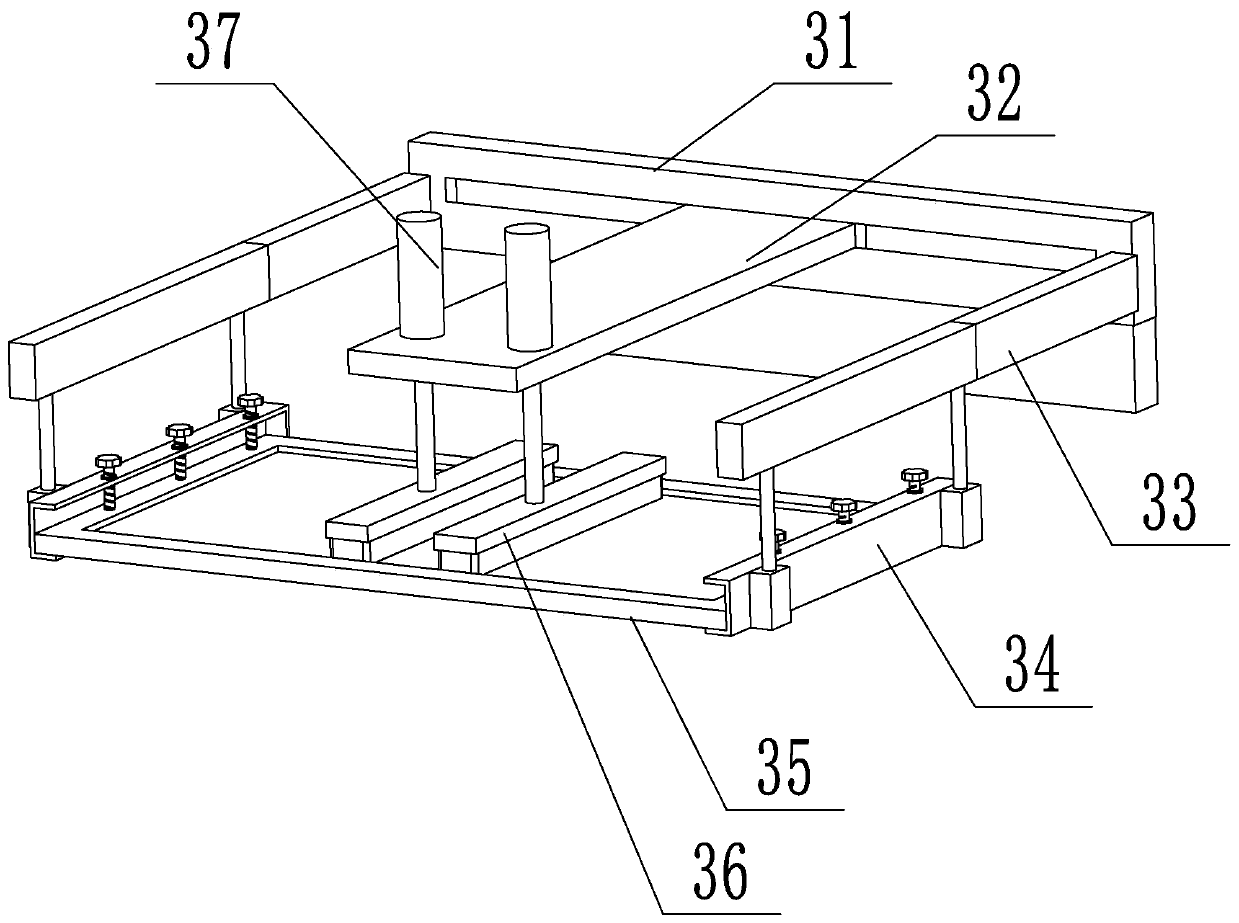

[0037] refer to figure 1 , figure 2 , printing mechanism 3 comprises vertical plate 2 on the frame, horizontal plate 31 that is slidably installed on vertical plate 2, movable seat 32 that is slidably installed on horizontal plate 31 and brush plate 35 and silk screen 36 below movable seat 32. Two horizontal connecting plates are installed on the horizontal plate 31, and the connecting plate is formed with a vertical vertical bar 33, and the bottom of the vertical bar 33 is connected with a placement plate 34, and the side of the placing plate 34 is formed with a placement groove, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com