Sheet breaking table with glass transfer function

A glass transfer and function technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of glass breaking table without transmission mechanism, reducing glass processing efficiency, single function and other problems, achieving fast transmission, reducing glass Waste of resources, reducing the effect of instantaneous suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

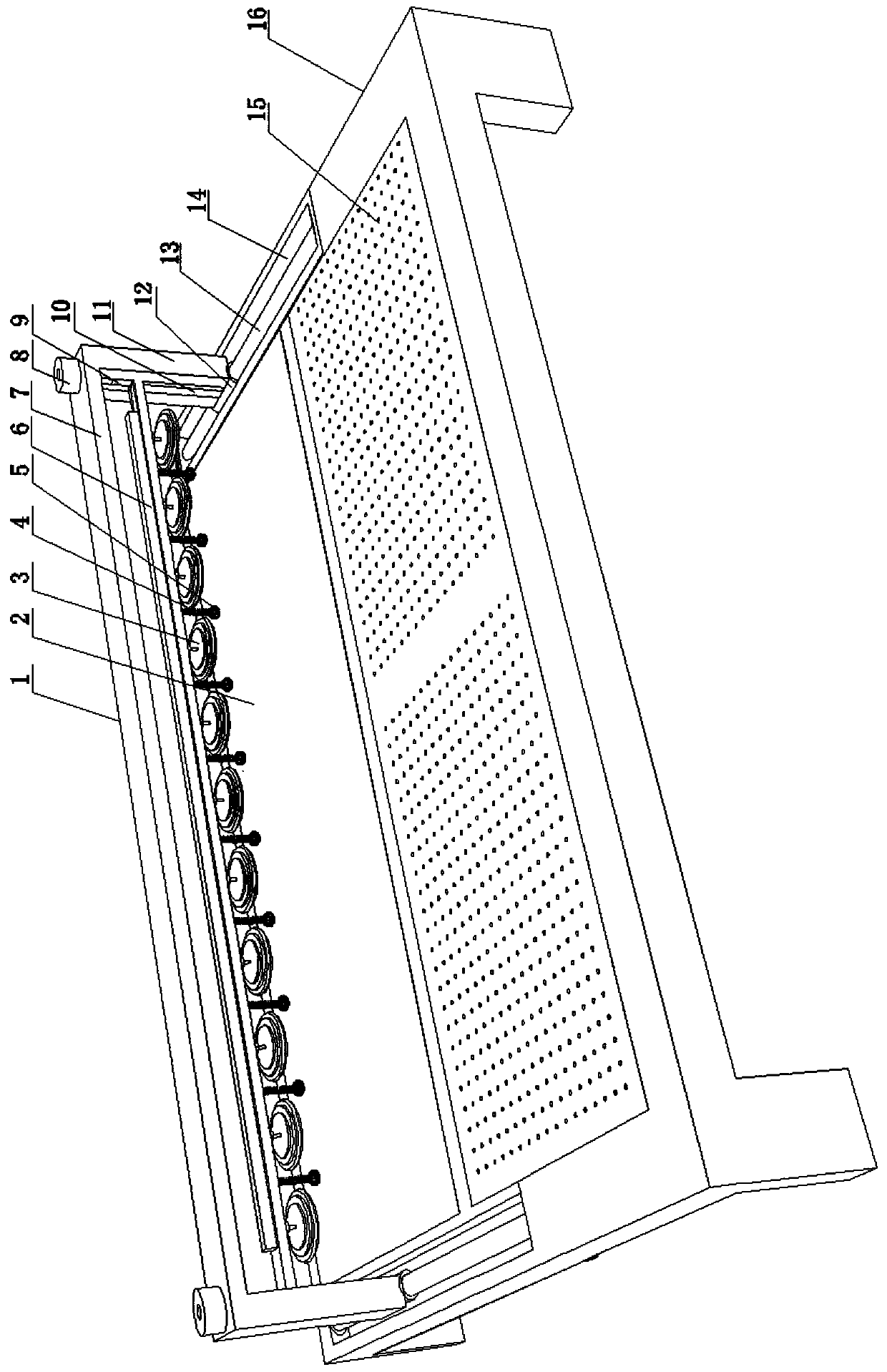

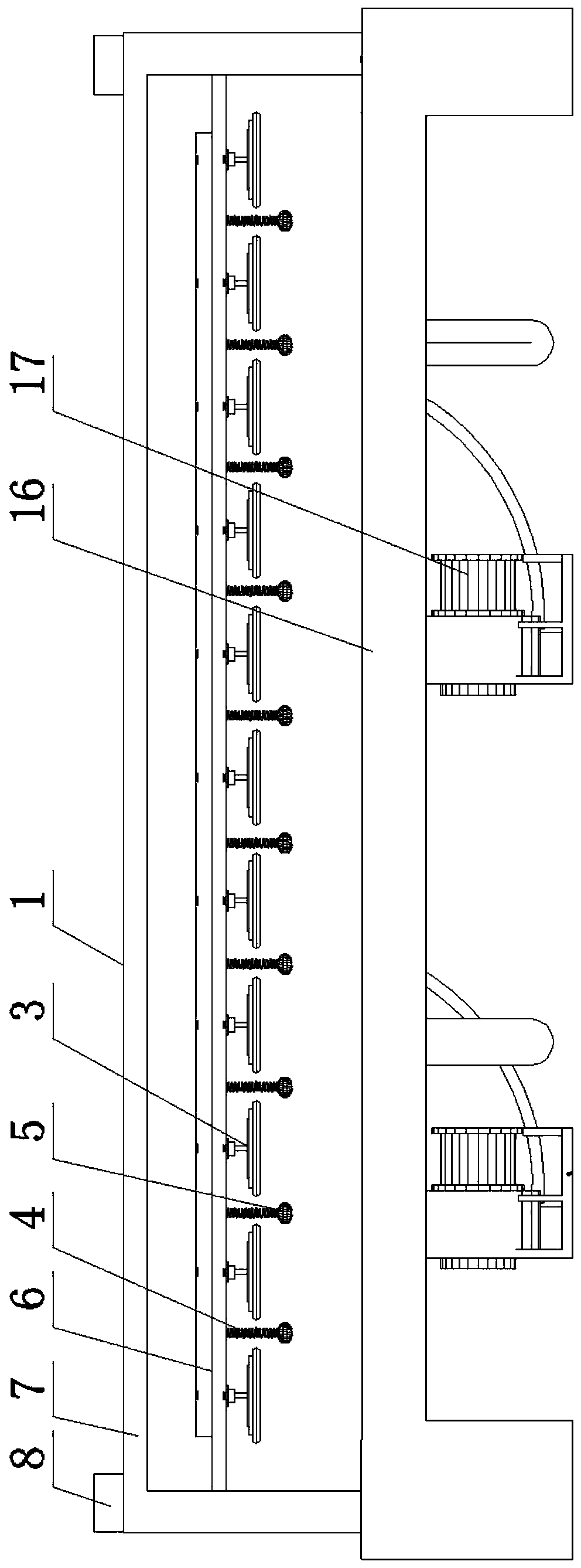

[0023] A breaking table with a glass transfer function, comprising a frame 16 and a breaking table, the frame is provided with a breaking table, a plurality of mounting holes are arranged at intervals on the breaking table, and a number of mounting holes are embedded in the mounting holes. An air nozzle connected to the air source, the top of the air nozzle is flush with the top surface of the breaking table; the air nozzle is set upwards to spray the air flow that supports the glass upwards, the width of the breaking table is relatively large, and one side is Breaking sheet working area 15, the other side is the buffer glass area 2, and the frame of the buffer glass area is also provided with a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com