LCD glass cutting system

A glass cutting and glass technology, which is applied in the field of LCD glass cutting system, can solve problems affecting quality, easy failure, easy glass breakage, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

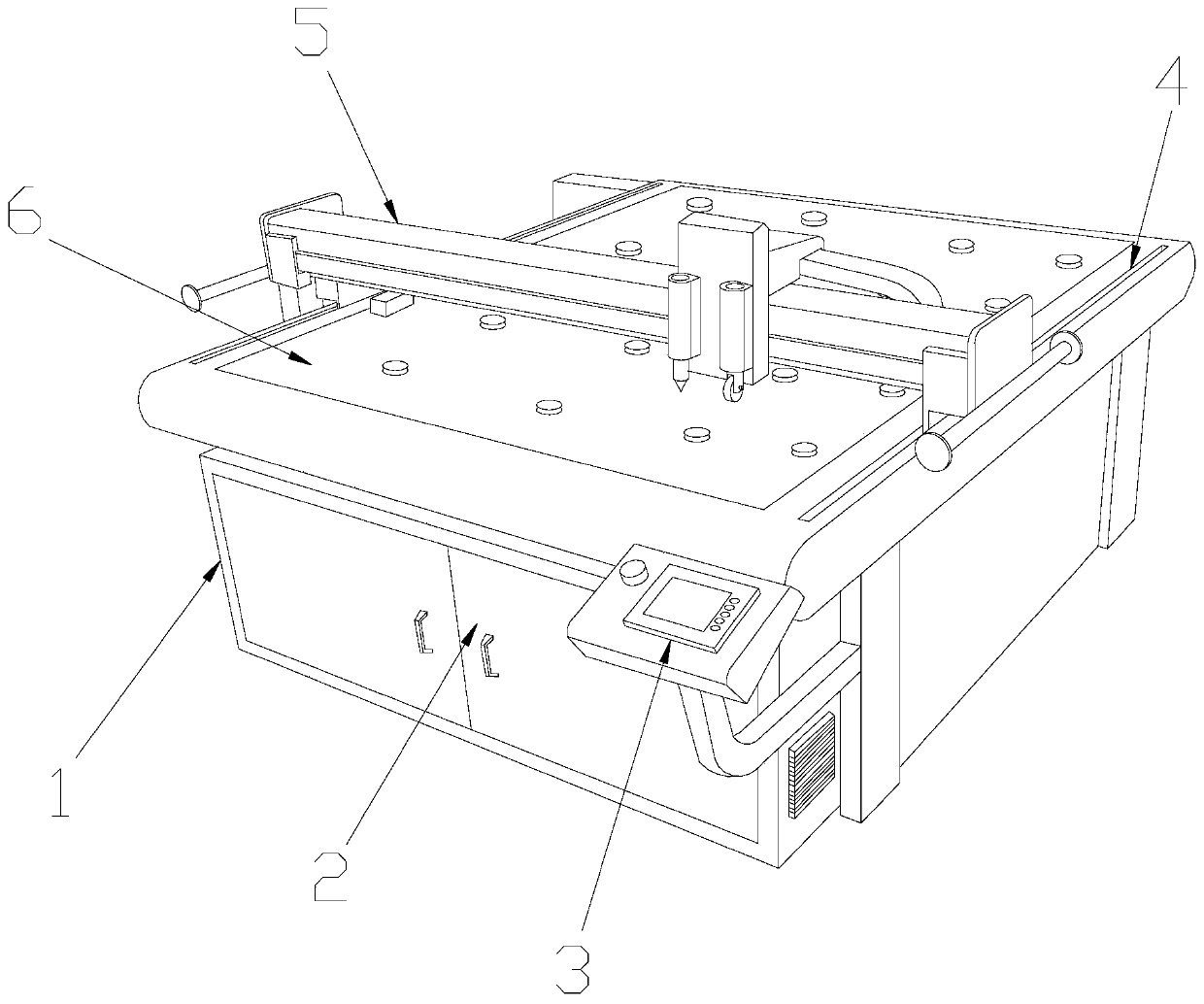

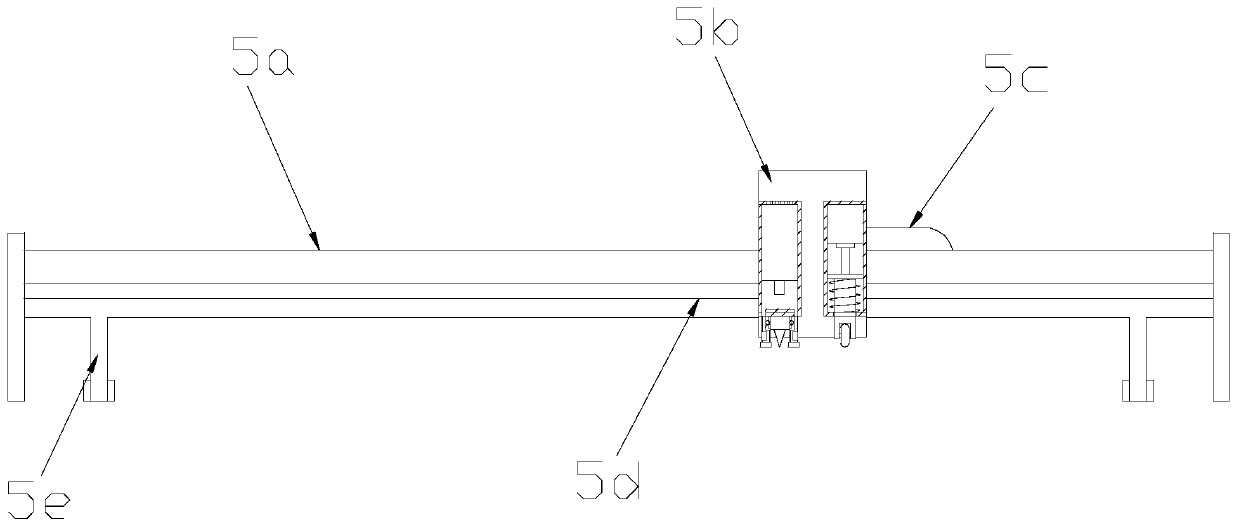

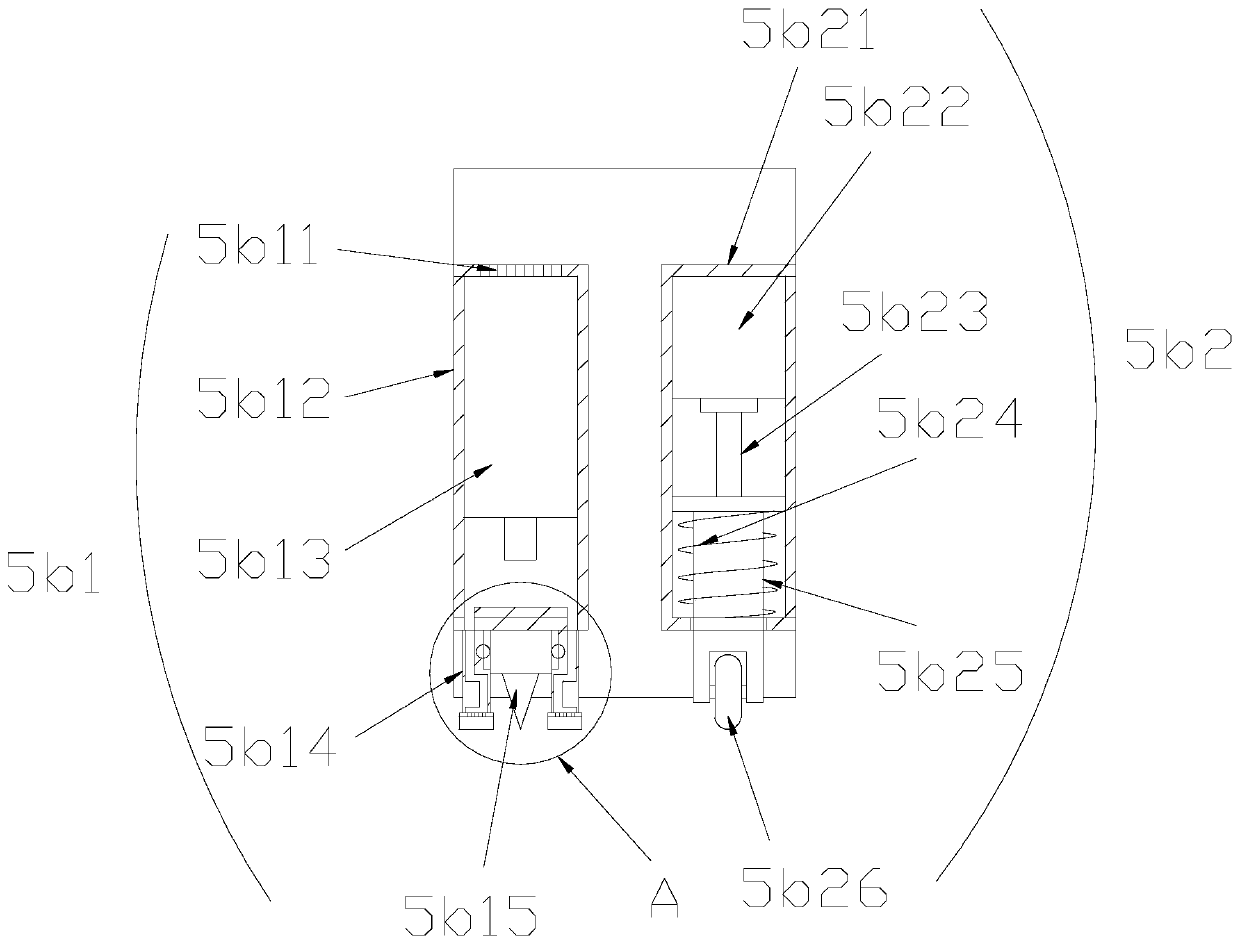

[0026] see Figure 1-Figure 5 , the present invention provides an LCD glass cutting system, the structure of which includes a glass cutting machine 1, a machine door 2, an electric controller 3, a vertical slide rail 4, a sliding mechanism 5, and a workbench 6. The front end of the glass cutting machine 1 An organic door 2 is installed on the top, and a workbench 6 is arranged on the top of the glass cutting machine 1. The glass cutting machine 1 is mechanically connected with the workbench 6, and the surface of the workbench 6 is provided with a vertical slide rail 4 , the top of the workbench 6 is provided with a sliding mechanism 5, the workbench 6 and the sliding mechanism 5 are slidably matched through the vertical slide rail 4, and the surface of the glass cutting machine 1 is equipped with an electric controller 3 , the sliding mechanism 5 is composed of a sliding frame 5a, a guide cutting frame 5b, a drag chain 5c, a transverse slide rail 5d, and a sliding plate 5e. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com