Laser repairing method for repairing cracks of ultrahigh temperature ceramic coating on C/C composite material

A technology of ultra-high temperature ceramics and composite materials, applied in the field of laser surface engineering, can solve problems such as coating defects, and achieve the effects of low cost, rapid processing and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

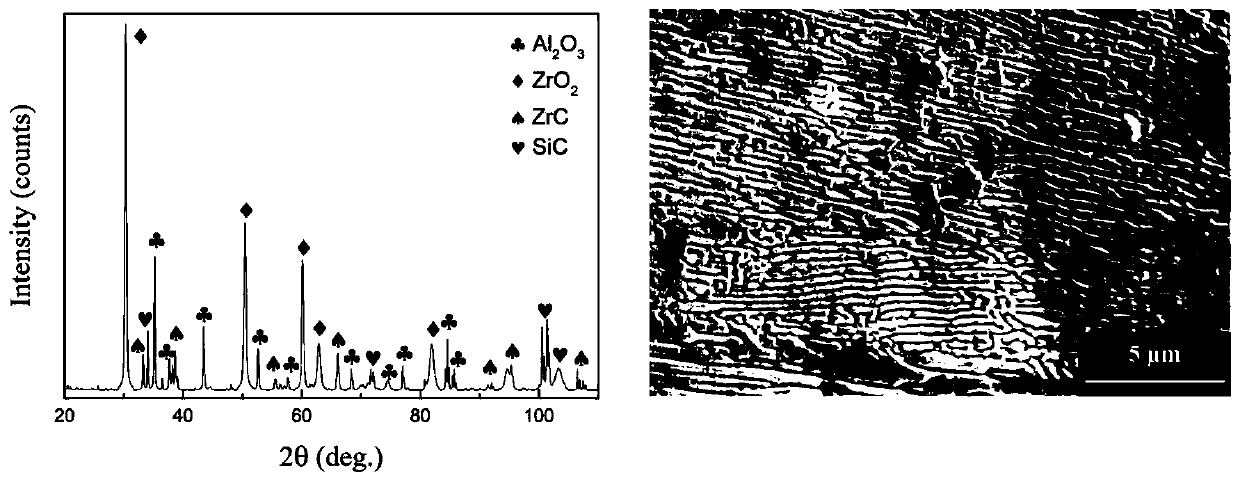

[0026] 1) Cut the C / C composite material to obtain a long sample with a size of 45×8×4 mm, ultrasonically clean it with absolute ethanol for 30 minutes, and then dry it for later use. Using Si powder, C powder and ZrC powder as raw materials, SiC-ZrC-Al was prepared on the surface of C / C composite materials by embedding method 2 o 3 coating. A three-point bending static test was carried out on the coated C / C composite material to obtain samples with cracks distributed on the surface (such as figure 1 shown) for the subsequent repair of the main crack.

[0027] 2) Confirm the location of the main crack on the surface of the coating. First, use a file to groove the location, and then use 180# and 320# sandpaper to polish it respectively. Be careful not to damage the C / C substrate during grooving and grinding, and then The sample was ultrasonically cleaned with absolute ethanol for 30 min, and dried in an oven.

[0028] 3) The powder used for repair is made of Al 2 o 3 (300...

Embodiment 2

[0031] 1) Cut the C / C composite material to obtain a long sample with a size of 45×8×4 mm, ultrasonically clean it with absolute ethanol for 30 minutes, and then dry it for later use. Using Si powder, C powder and ZrC powder as raw materials, SiC-ZrC-Al was prepared on the surface of C / C composite materials by embedding method 2 o 3 coating. A three-point bending static test was carried out on the coated C / C composite material to obtain a sample with cracks on the surface, so as to repair the main cracks later.

[0032]2) Confirm the location of the main crack on the surface of the coating. First, use a file to groove the location, and then use 180# and 320# sandpaper to polish it respectively. Be careful not to damage the C / C substrate during grooving and grinding, and then The sample was ultrasonically cleaned with absolute ethanol for 30 min, and dried in an oven.

[0033] 3) The powder used for repair is made of Al 2 o 3 (300 mesh) and ZrO 2 (300 mesh) powder composi...

Embodiment 3

[0036] 1) Cut the C / C composite material to obtain a long sample with a size of 45×8×4 mm, ultrasonically clean it with absolute ethanol for 30 minutes, and then dry it for later use. Using Si powder, C powder and ZrC powder as raw materials, SiC-ZrC-Al was prepared on the surface of C / C composite materials by embedding method 2 o 3 coating. A three-point bending static test was carried out on the coated C / C composite material to obtain a sample with cracks on the surface, so as to repair the main cracks later.

[0037] 2) Confirm the location of the main crack on the surface of the coating. First, use a file to groove the location, and then use 180# and 320# sandpaper to polish it respectively. Be careful not to damage the C / C substrate during grooving and grinding, and then The sample was ultrasonically cleaned with absolute ethanol for 30 min, and dried in an oven.

[0038] 3) The powder used for repair is made of Al 2 o 3 (300 mesh) and ZrO 2 (300 mesh) powder compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com