Experimental device and method for organic contaminated soil remediation by coupling resistance heating with microorganisms

A technology for microbial remediation and organic pollution, applied in the field of soil remediation, can solve the problems of high cost, low remediation efficiency, long remediation cycle, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

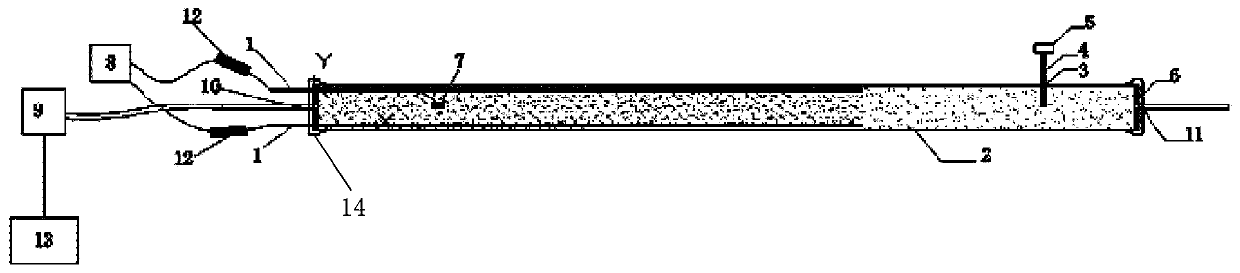

[0083] The resistance heating coupled microbial remediation experiment device of organic polluted soil provided in this embodiment, such as figure 1 As shown, the main body of the device is a quartz glass tube with an inner diameter of 6 cm and a length of 90 cm, which is filled with organic polluted soil as a pollution source, and a gas sampling port is set on the side wall near the rear port of the quartz glass tube. The sampling port is 10cm away from the outlet of the quartz glass tube, and a nickel-plated needle with an outer diameter of 3mm and a length of 6cm is installed on the gas sampling port, and a micro valve is installed on the nickel-plated needle; , Rear sealing end pieces, fine mesh screens are installed on each sealing end piece. Install two threaded stainless steel electrodes with an outer diameter of 4 mm and a length of 62 cm at the front opening of the quartz glass tube as electrode components, and an electrically insulated K-type thermocouple is installe...

Embodiment 2

[0088] This embodiment provides an experimental device for resistive heating coupling microorganisms to remediate organically polluted soil, such as figure 1 As shown, the main body of the experimental device is a quartz glass tube with an inner diameter of 6 cm and a length of 90 cm, filled with soil inside; a gas sampling port is arranged on the side wall of the tube near the outlet, 10 cm away from the rear end opening of the quartz glass tube, A nickel-plated needle with an outer diameter of 3mm and a length of 6cm is installed at the gas sampling port, and a micro valve is installed on the needle; the front opening and the rear opening of the quartz glass tube are respectively equipped with front and rear sealing end pieces. There is a fine mesh sieve. Install two threaded stainless steel electrodes with an outer diameter of 4 mm and a length of 62 cm at the front opening of the quartz glass tube as an electrode assembly. An electrically insulated K-type thermocouple is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com