Concrete freeze-thaw-resistant composite protective agent and preparation method thereof

A freeze-thaw resistance, protective agent technology, applied in biochemical equipment and methods, microorganism-based methods, immobilized on/in organic carriers, etc., can solve the problem of inability to further improve mechanical strength, general concrete performance, molecular structure Small problems, to achieve good compatibility and chemical stability, improve anti-freeze-thaw effect, prolong the effect of survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

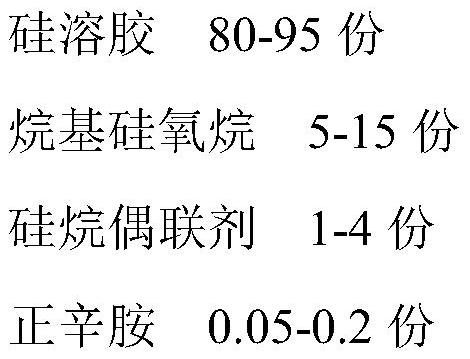

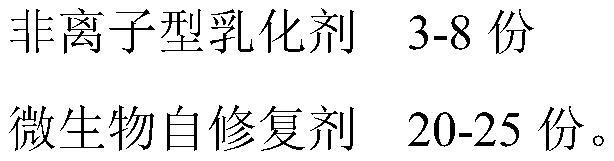

Method used

Image

Examples

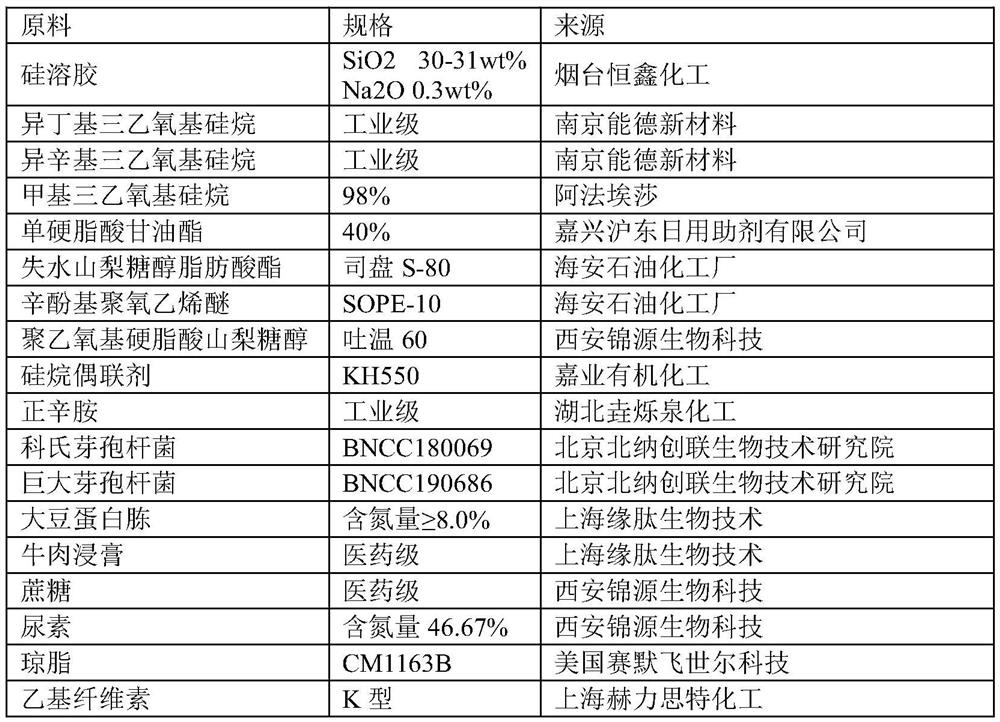

Embodiment 1

[0048]A concrete anti-freeze-thaw composite protective agent, weigh 90g of silica sol, 10g of methyltriethoxysilane, 3g of Span S-80 and 2g of SOPE-10, respectively, add them to a conical flask at 26°C, and stir Until the mixture is uniform; weigh 2g of silane coupling agent KH550, add it into the Erlenmeyer flask under stirring, continue to stir for 20min until the solution is uniform, then slowly add 0.2g of n-octylamine dropwise, and stir until a transparent and stable sol is obtained; under stirring Add deionized water at 60°C to the sol, and continue stirring for 1 hour to obtain the primary protective agent.

[0049] Microbial self-healing agents are made by the following steps:

[0050] S1: Weigh the following raw materials: 3g peptone, 2g beef extract, 1g sucrose and 94g urea; add peptone and beef extract to 1L deionized water to prepare medium 1;

[0051] S2: adjust its pH to 7.0, put it in a Erlenmeyer flask, autoclave at 130°C for 30 minutes, take it out and dry it...

Embodiment 2-3

[0056] Examples 2-3 relate to a concrete antifreeze-thaw composite protective agent, all of which are based on Example 1, and the only difference is that the amount of the microbial self-healing agent is different during the preparation process, see Table 2 for details.

[0057] Table 2 Example 2-3

[0058] Example Amount of microbial self-healing agent / g Example 2 20 Example 3 22

Embodiment 4-6

[0060] Examples 4-6 relate to a concrete antifreeze-thaw composite protective agent, all of which are based on Example 1. The only difference lies in the selection of raw materials and the amount of raw materials used in the preparation process. See Table 3 for details.

[0061] Table 3 Example 4-6

[0062]

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com