A kind of prepreg and preparation method thereof

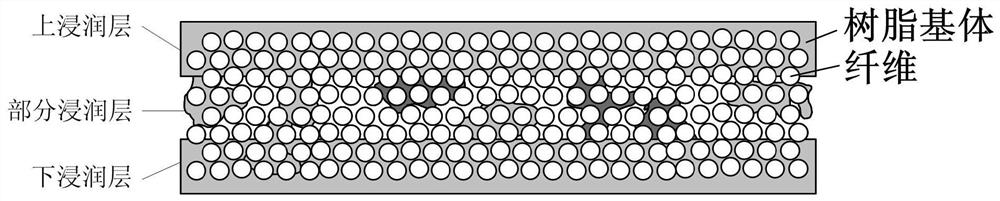

A technology of prepreg and impregnation layer, which is applied in the field of prepreg and its preparation, can solve the problems of expensive process cost, poor pavement, high equipment investment, etc., and achieve low comprehensive manufacturing cost, reduced resin consumption, and reduced material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

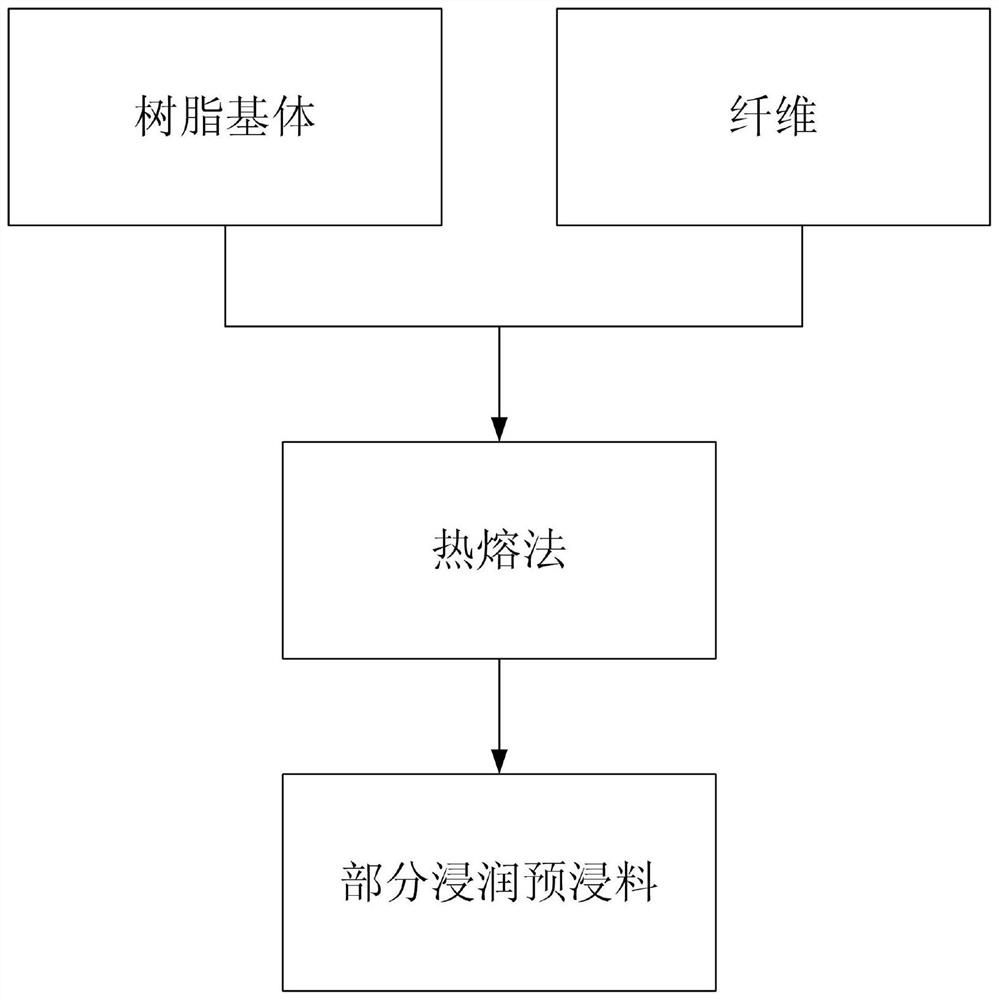

Method used

Image

Examples

Embodiment 1

[0050] Prepreg:

[0051] T700 continuous carbon fiber 65~68wt%

[0052] 3068 resin 32~35wt%

[0053] Prepreg wetting degree 70~75%

[0054] The compounding temperature for prepreg preparation is 65°C, the resin viscosity is 21000mPa.s, and the compounding pressure is adjusted according to the wettability of the prepreg.

[0055] The prepreg prepared in this example adopts the OOA preparation process to obtain the composite material, and the process is as follows:

[0056] 1. Cutting.

[0057] Cut 16 layers of 320*320mm 0° prepreg with an automatic cloth cutting machine.

[0058] 2. Layering.

[0059] Lay the first layer of prepreg on the surface of the mold, then seal it with a vacuum bag, and pre-compact it under vacuum at room temperature for 15 minutes. After that, after laying three layers of prepregs, use vacuum bags to seal them at room temperature and vacuumize and precompact for 15 minutes until all prepregs are laid up and all prepreg fibers are in one direction...

Embodiment 2

[0068] Prepreg:

[0069] T700 continuous carbon fiber 65~68wt%

[0070] 3180 resin 32~35wt%

[0071] Prepreg wetting degree 75-80%

[0072] The compounding temperature for prepreg preparation is 75°C, the resin viscosity is 28000mPa.s, and the compounding pressure is adjusted according to the wettability of the prepreg.

[0073] The prepreg prepared in this example adopts the OOA preparation process to obtain a composite material. The pre-curing temperature of the composite material OOA is 90 ° C, and the post-curing temperature is 180 ° C. Others are the same as in Example 1. The prepared composite material has bending properties, interlayer shear The shear strength and porosity are shown in Table 1.

Embodiment 3

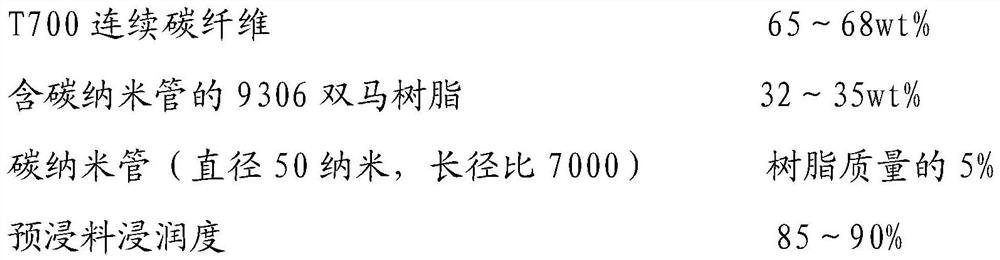

[0075] Prepreg:

[0076] T700 continuous carbon fiber 65~68wt%

[0077] 9306 Shuangma resin 32~35wt%

[0078] Prepreg wetting degree 80~85%

[0079] The compounding temperature for prepreg preparation is 75°C, the resin viscosity is 25000mPa.s, and the compounding pressure is adjusted according to the degree of infiltration of the prepreg.

[0080] The prepreg prepared in this example adopts the OOA preparation process to obtain a composite material. The pre-curing temperature of the composite material OOA is 100 ° C, and the post-curing temperature is 200 ° C. Others are the same as in Example 1. The prepared composite material has bending properties, interlayer shear The shear strength and porosity are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com