Recovery and recycling system for waste slurry in formation of rotary-jet piles or stir-jet piles

A circulatory system and a technology of agitating and spraying piles, applied in sheet pile walls, drilling equipment, drilling equipment and methods, etc., can solve the problem of limited ability to absorb cement slurry, reduce waste, ensure pile quality and operation. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

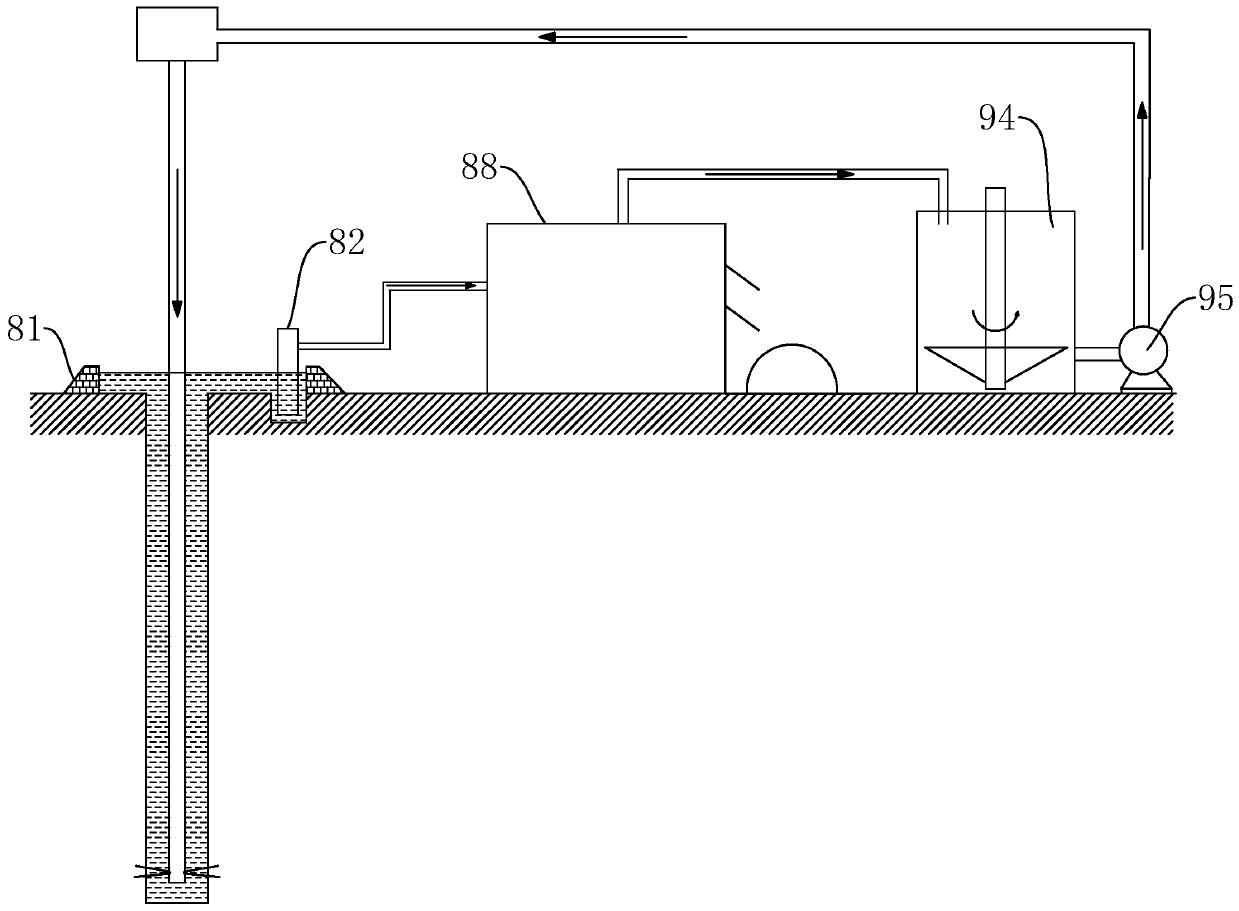

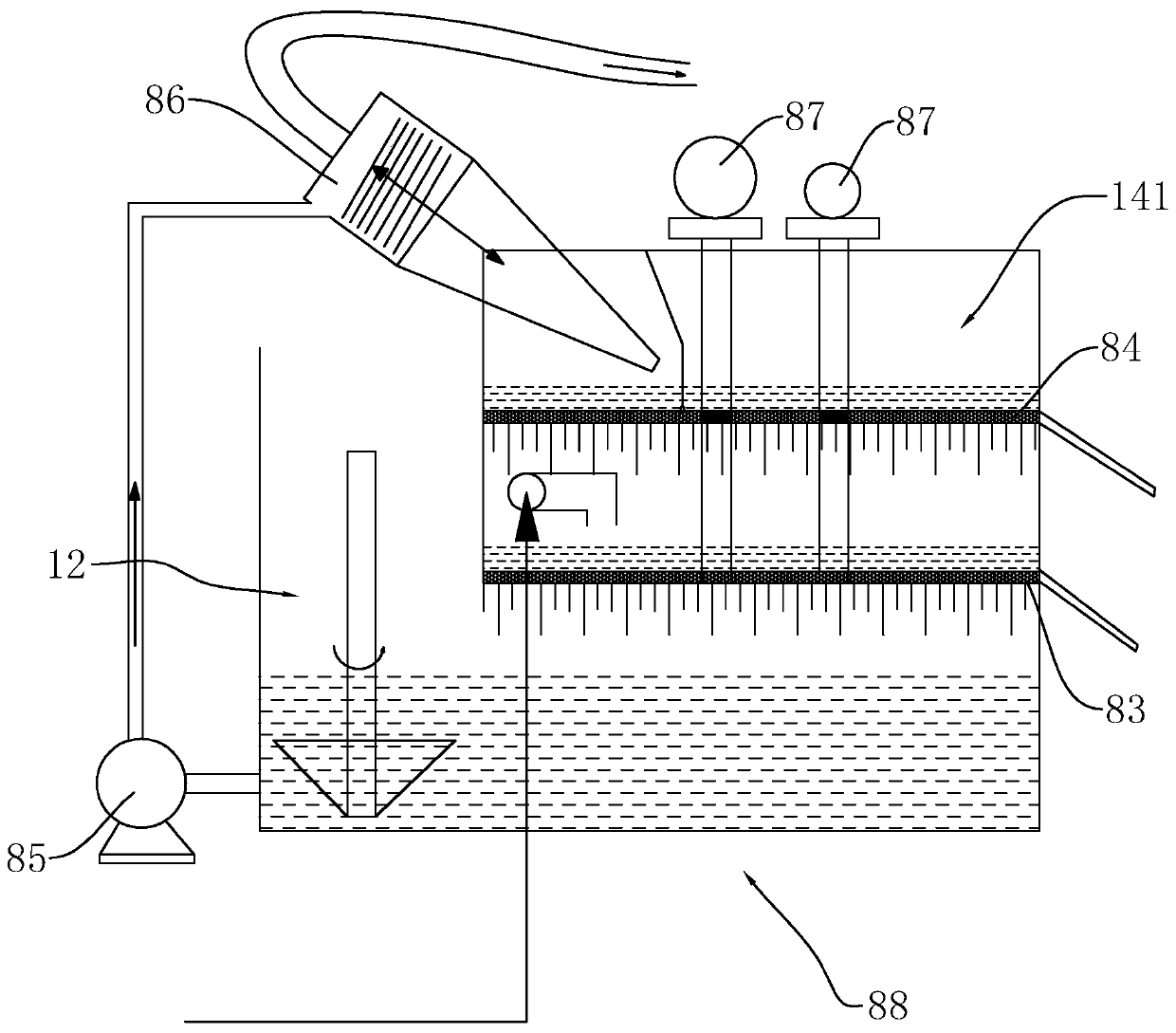

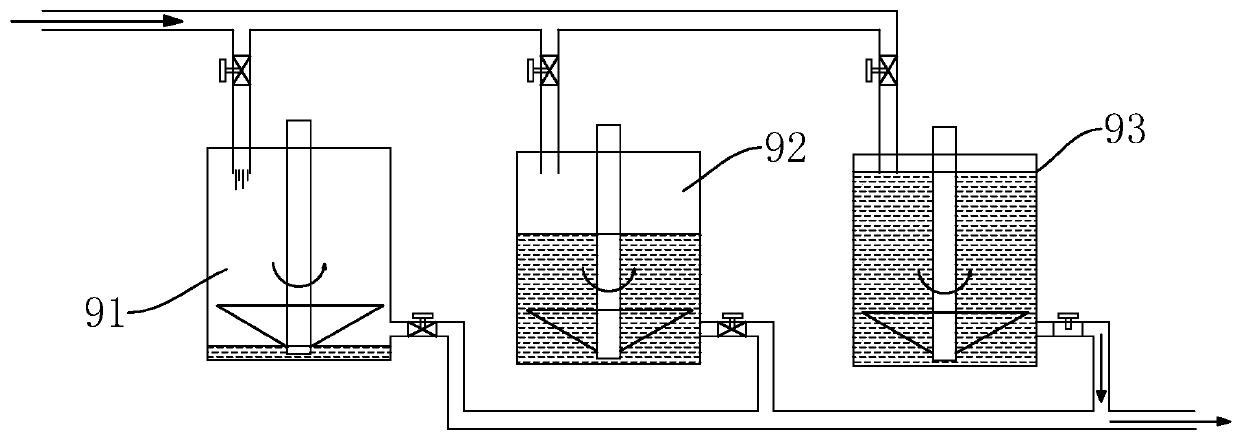

[0037] Such as figure 1 As shown, a waste slurry recycling system of rotary grouting pile or stirring spraying pile, during the construction process of rotary spraying or stirring spraying, cement waste slurry flows out continuously from the hole opening, and a surrounding wall is set at the hole opening The weir 81 collects the waste cement slurry with enclosures. The cofferdam 81 is provided with a first mud pump 82 . The first mud pump 82 collects the waste cement slurry flowing out of the orifice and pumps it into the slurry purification equipment 88 . refer to figure 2 After cement waste slurry enters the cement slurry purification equipment 88, it first passes through the coarse screen 83 to filter the coarse particles, and the filtered waste slurry enters the slurry storage tank 12; the slurry storage tank 12 is provided with a stirring system, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com