Mixing and discharging multifunctional pipeline system

A pipeline system and multi-functional technology, applied in the field of mixed multi-function pipeline system, can solve the problem of the whole line being unusable, and achieve the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

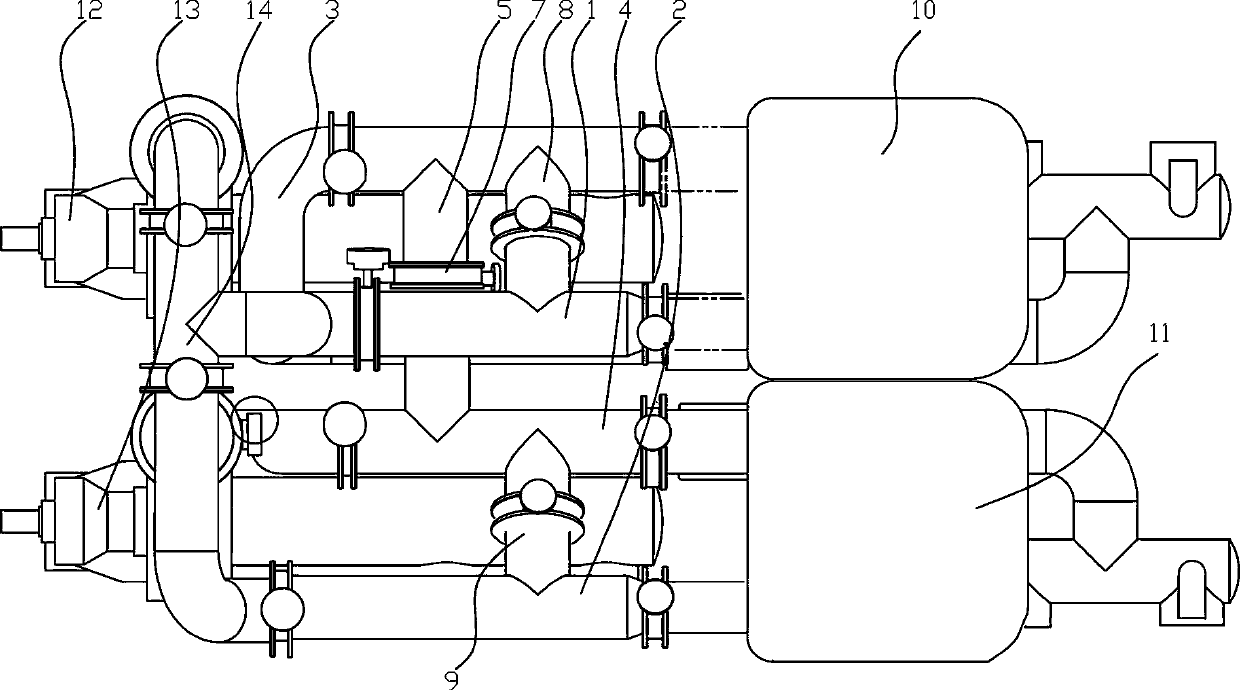

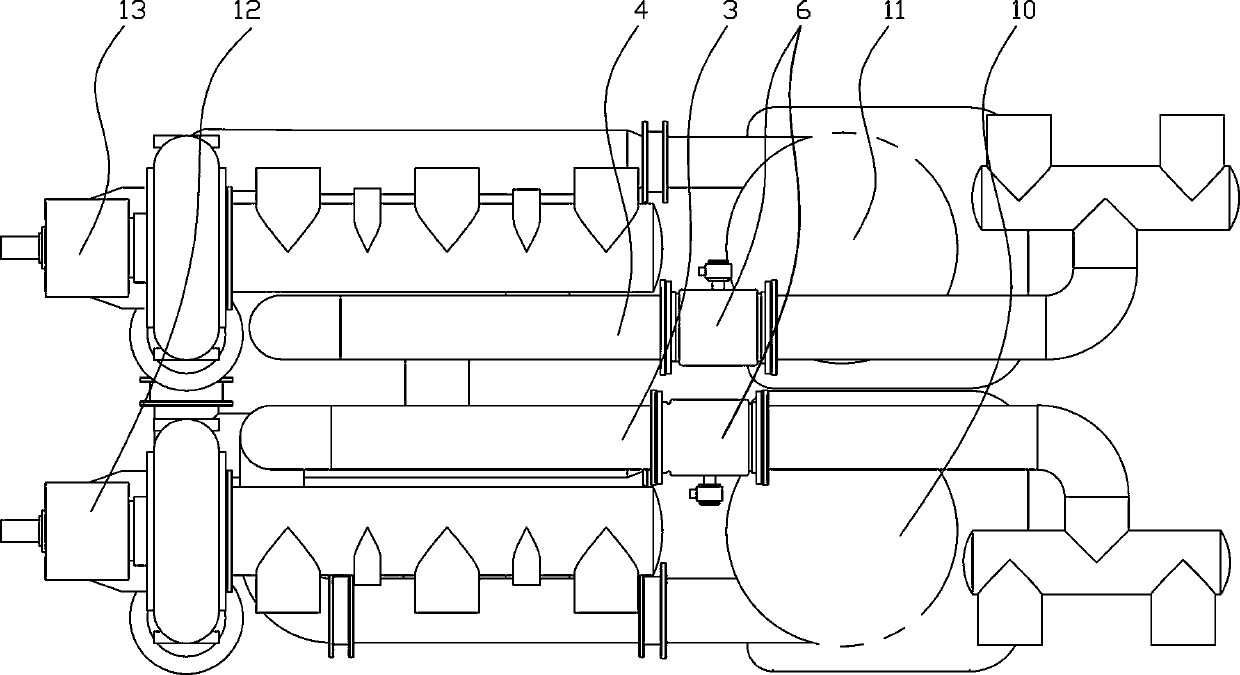

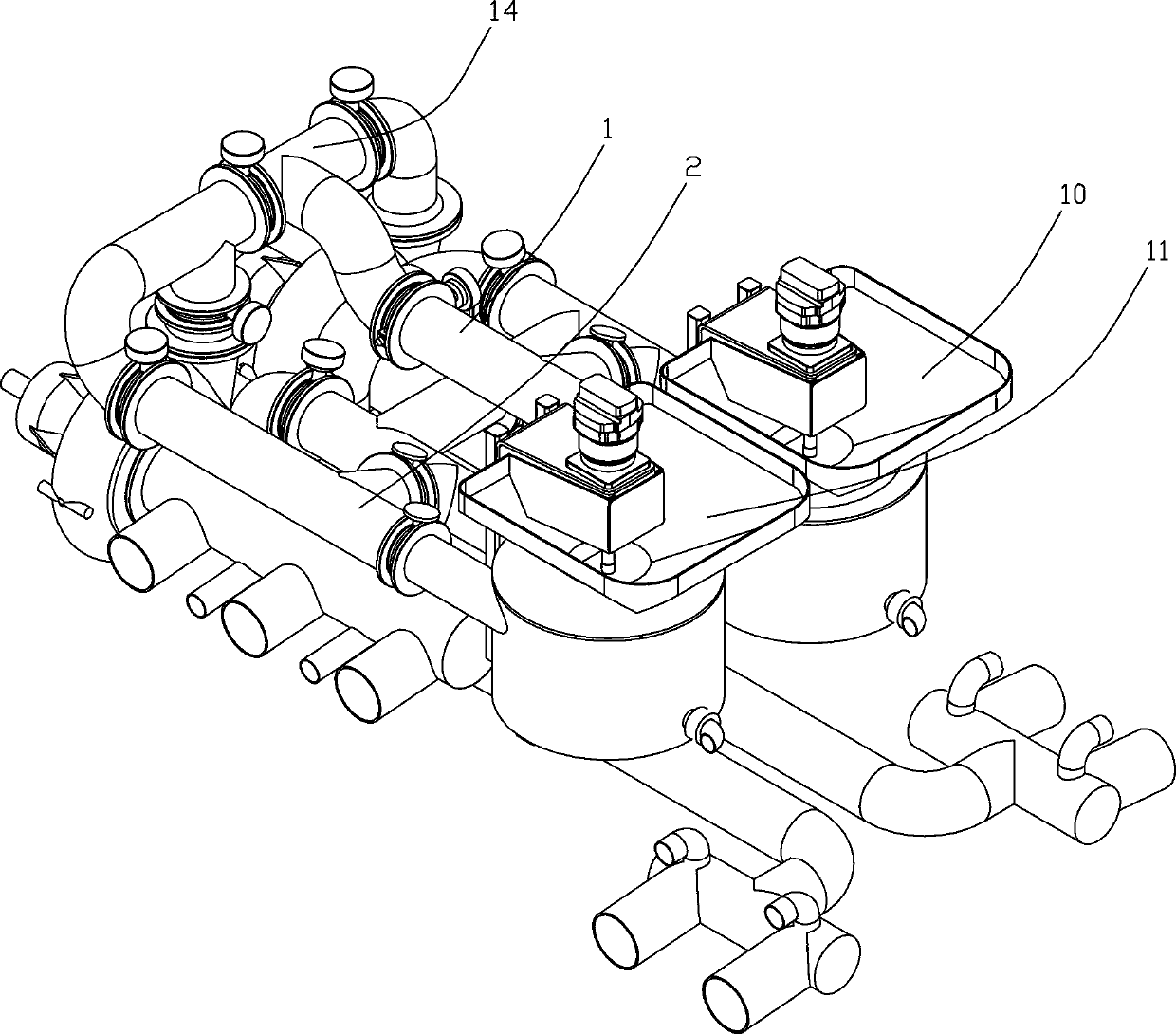

[0027] Such as Figure 1~4 Among them, a multifunctional pipeline system for mixed drainage, including a first mixed drainage access pipeline 1, a first mixed drainage outlet pipeline 3, a second mixed drainage inlet pipeline 2 and a second mixed drainage outlet pipeline 4 , Between the first mixed discharge outlet pipeline 3 and the second mixed discharge outlet pipeline 4, an outlet connecting pipe 5 is provided, and a valve member 7, such as a butterfly valve 707, is provided on the outlet connecting pipe 5. The valve parts are electronically controlled or hydraulically controlled valve parts. The valve element 7 in this example is preferably a butterfly valve. Electric or hydraulic control butterfly valves facilitate automatic or remote switching operations. With this structure, when a problem occurs in one outlet pipeline, one outlet pipeline can be switched to two mixing devices, or different discharge directions can be switched.

[0028] The preferred solution is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com