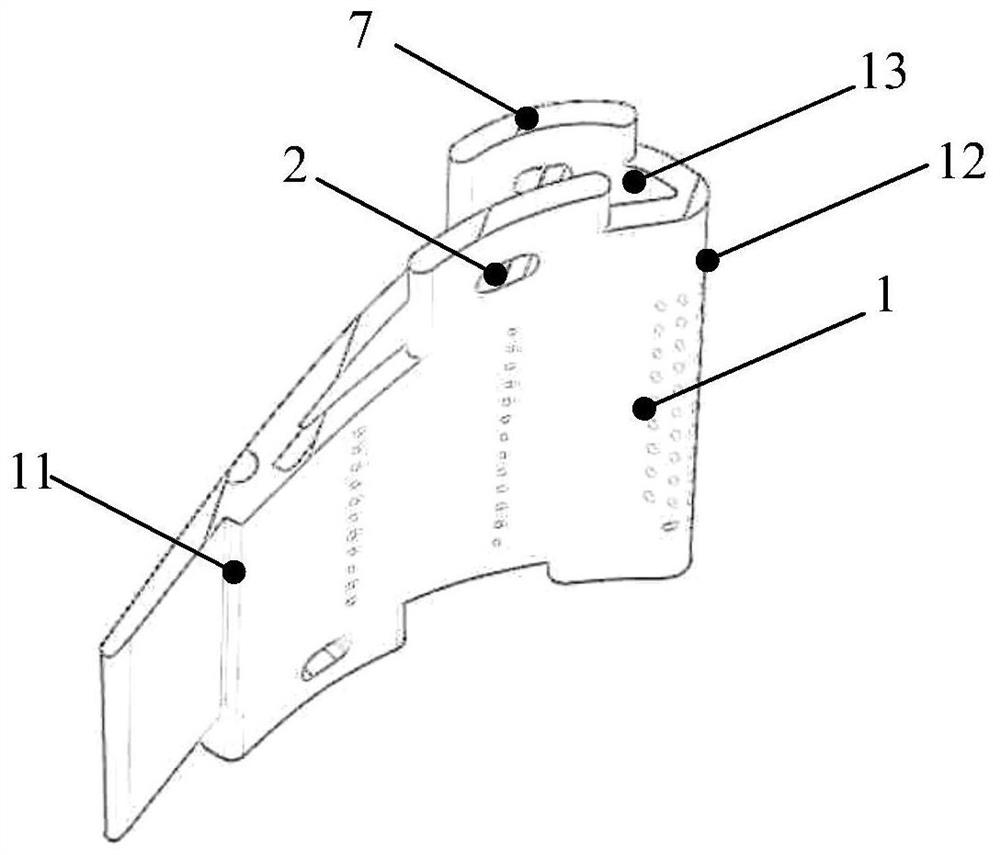

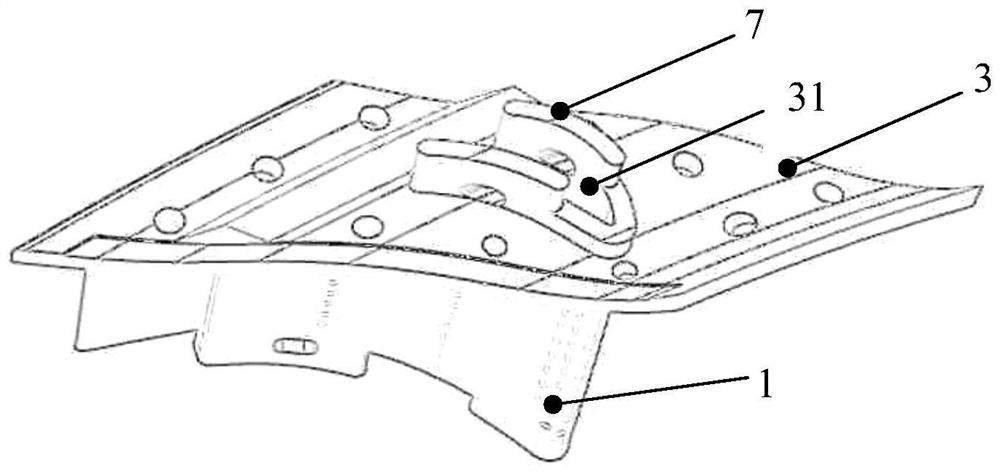

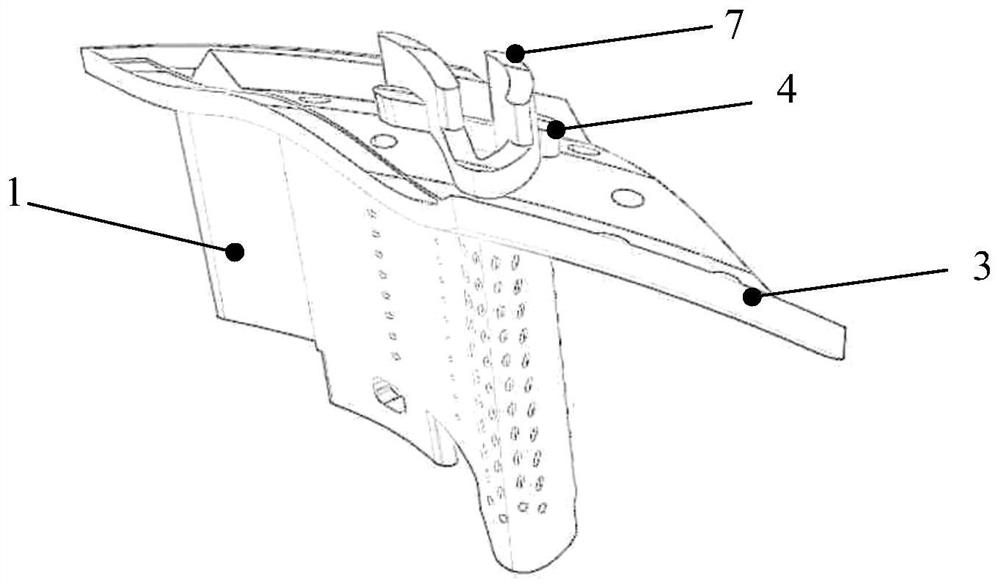

Structure and Forming of Aeroengine Ceramic Matrix Composite Fixed Guide Vane

An aero-engine and composite material technology, which is applied in the direction of engine components, machines/engines, stators, etc., can solve problems such as poor blade root strength, unreasonable design of CMC guide blade prefabrication, etc., to reduce costs, reduce manufacturing risks, The effect of improving component quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The dimensions of the CMC fixed guide vanes in this embodiment are: length 60mm, width 50mm, and height 120mm. In this embodiment, the raw material of the ceramic matrix composite material is SiC fiber, and the raw materials used in the preparation process are trichloromethylsilane and H 2 , Ar gas, etc.

[0056] Specific steps are as follows:

[0057] (1) Preparation of preforms: SiC fibers are woven into 2D plain weave fabrics, and other preform types such as 2.5D and 3D can also be used. The plain weave fabric is cut into a suitable size according to the size of the part, and the multi-layer plain weave fabrics are stacked, and punctured in the stacking direction of the plain weave fabrics. The same SiC fibers are used for the punctured fibers to form a SiC fiber preform. The SiC fiber preform is fixed and shaped using a mold.

[0058] (2) Preparation of the interface layer: the preform in step (1) is placed in a chemical vapor deposition furnace to prepare the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com