Finely-adjustable engine cooling water pump

An engine cooling and water pump technology, applied in engine cooling, engine components, machines/engines, etc., can solve the problems of inconvenient pump body, motor movement, and inconvenient adjustment of pump body flow, and achieve the effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

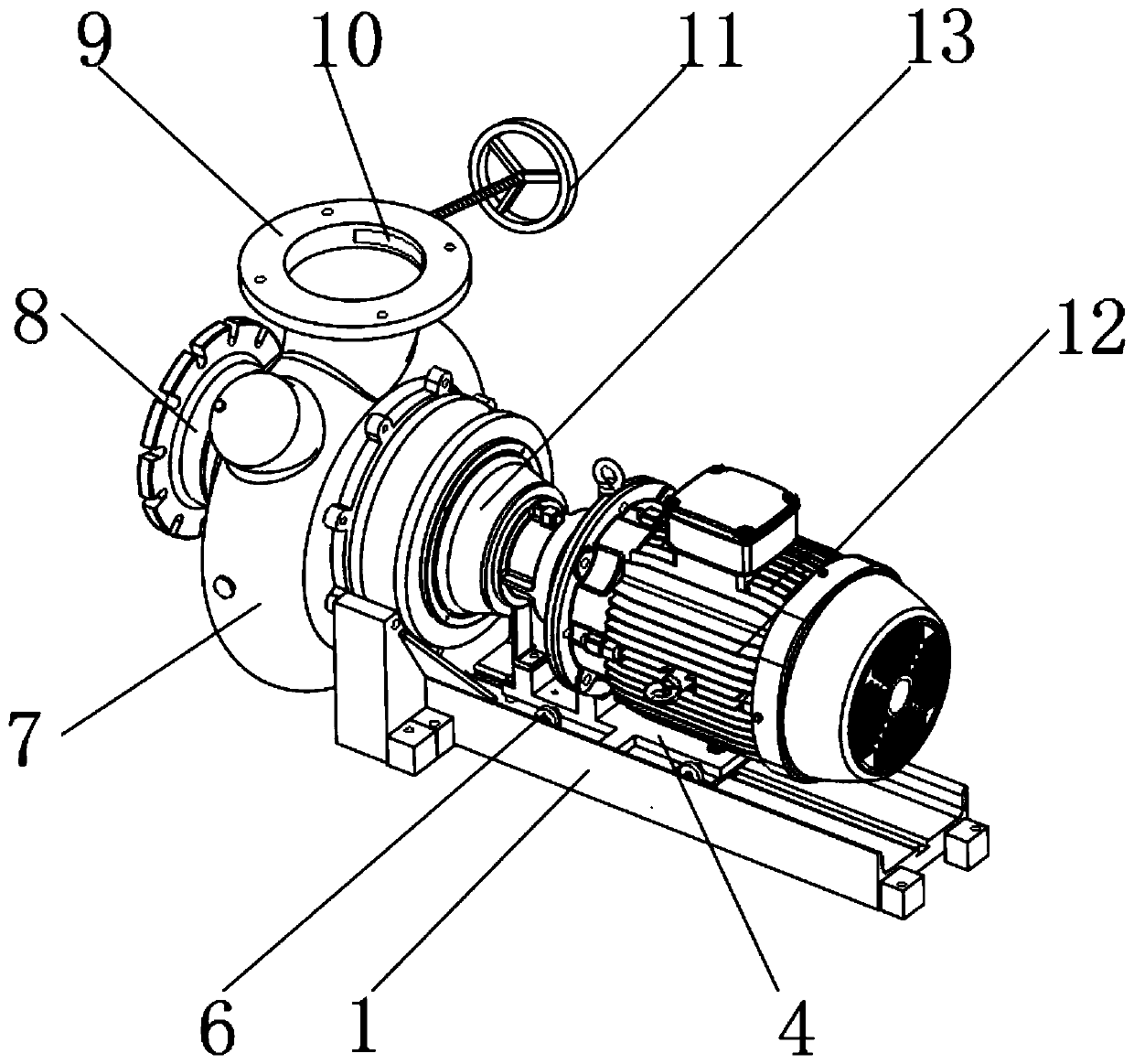

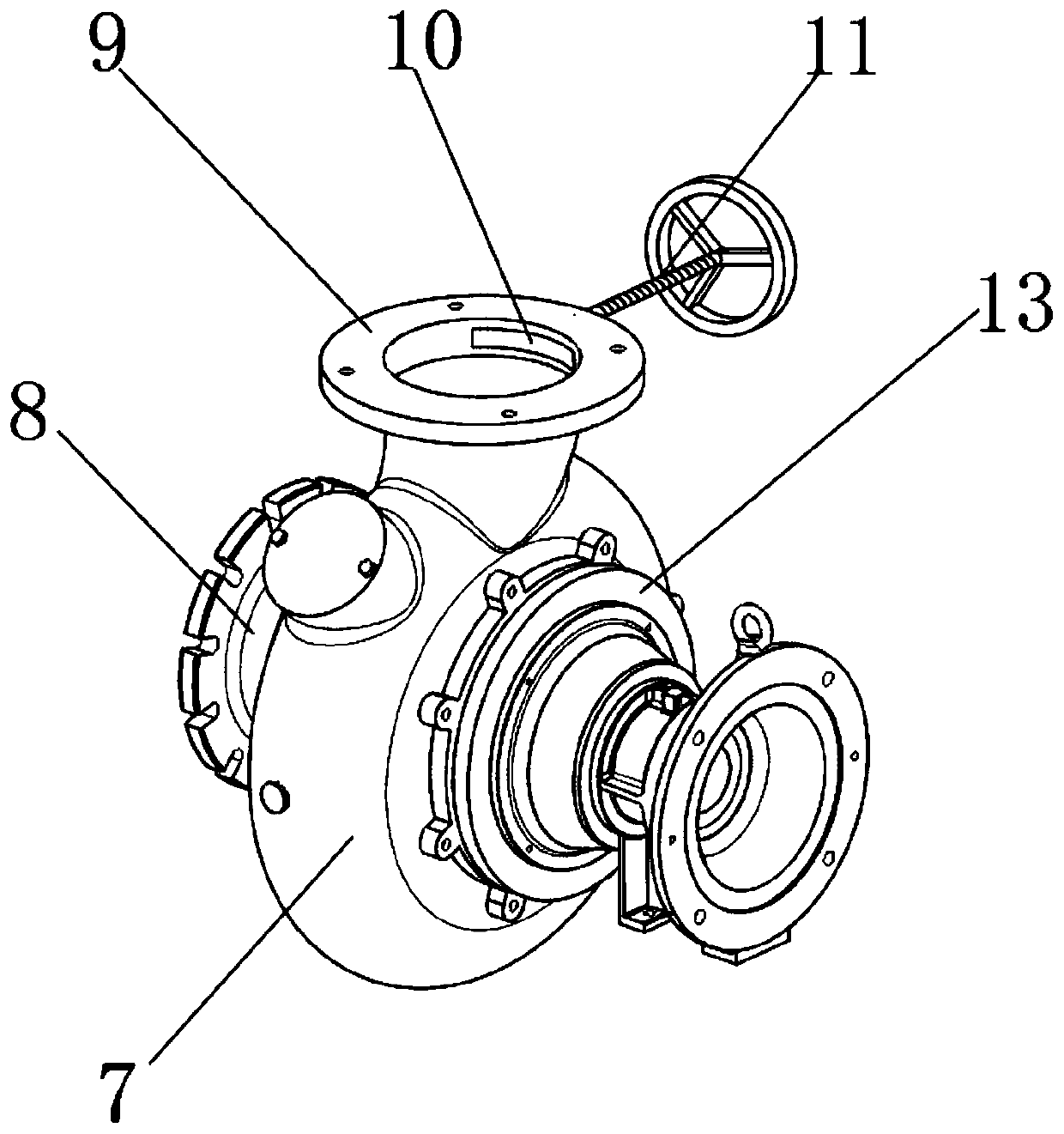

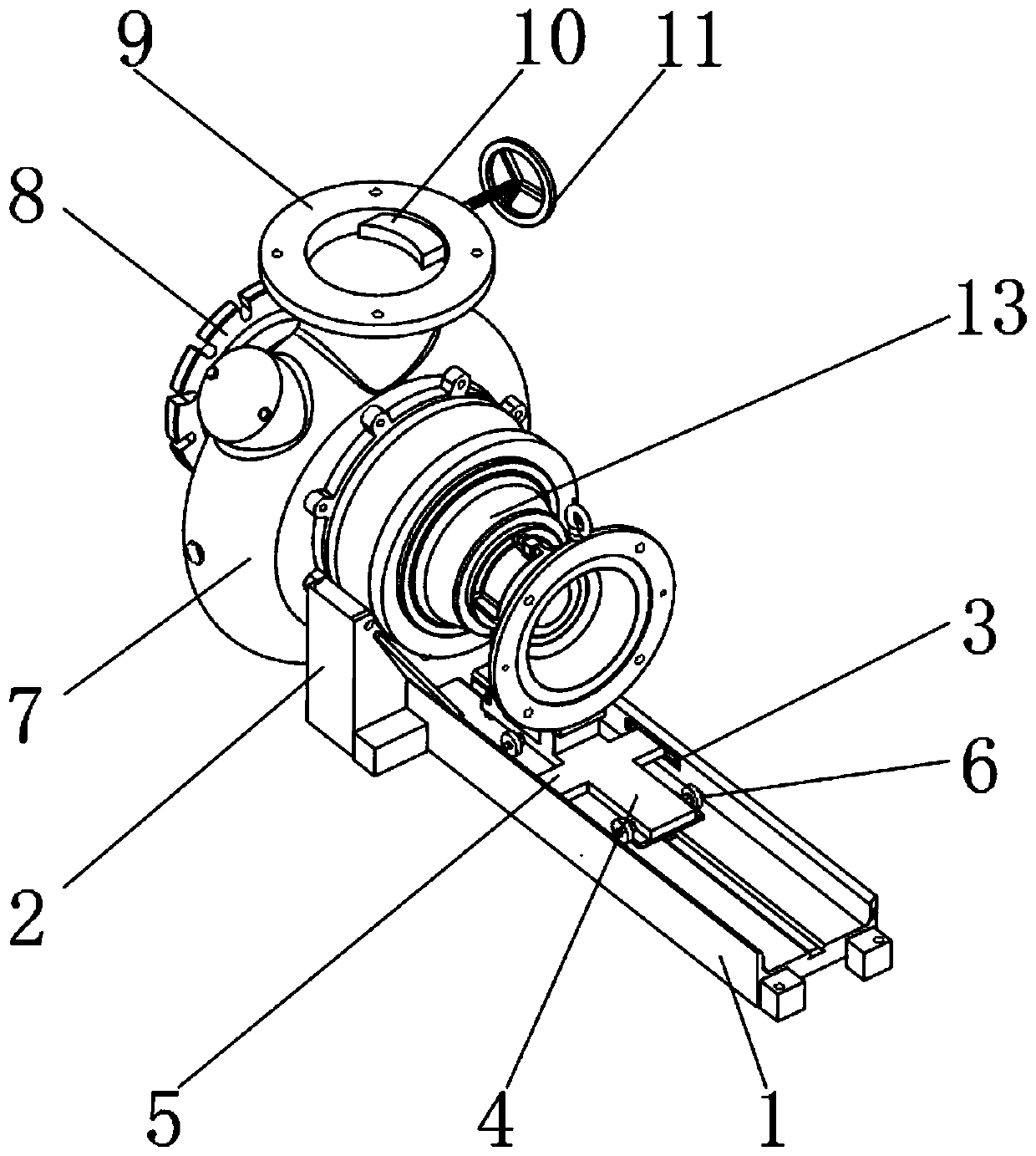

[0024] The fine-tunable engine cooling water pump of this embodiment, such as Figure 1-3 As shown, it includes a base 1, a pump body 7, a motor 12 and a connector 13. One end of the base 1 is fixed with a support frame 2. The inner wall of the base 1 is symmetrically provided with chute 3 on both sides, and a sliding seat 4 is slidably installed on the base 1. , both sides of the sliding seat 4 are fixed with a limit block 5, and the end of the limit block 5 away from the slide seat 4 is fixed inside the chute 3, and the periphery of the slide seat 4 is fixed with a pulley 6;

[0025] The pump body 7 is provided with a water outlet pipe 8 and a water inlet pipe 9. A sliding block 10 is movably installed on the inner wall of the water inlet pipe 9. The outer ring side of the sliding block 10 is fixedly connected to one end of the adjusting bolt 11 through a bearing, and the adjusting bolt 11 runs through it vertically. When the water inlet pipe 9 is closed, the adjustment bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com