Drum brake device for small aircraft and working method

A braking device and aircraft technology, applied in drum brakes, brake types, aircraft braking arrangements, etc., can solve the problems of slow braking system response, increased diameter, increased brake pedal stroke, etc., to improve braking efficiency , Improve the braking response, the effect of the overall compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

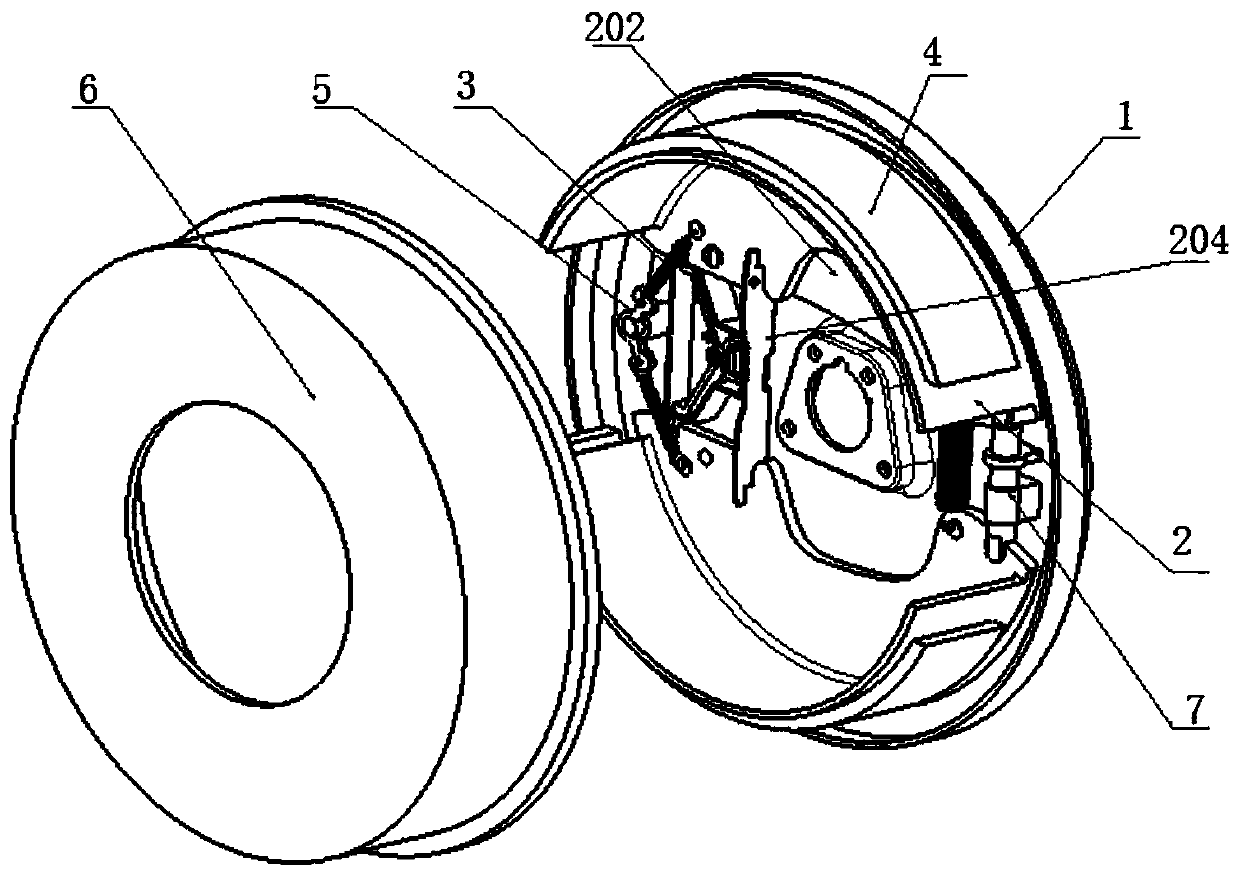

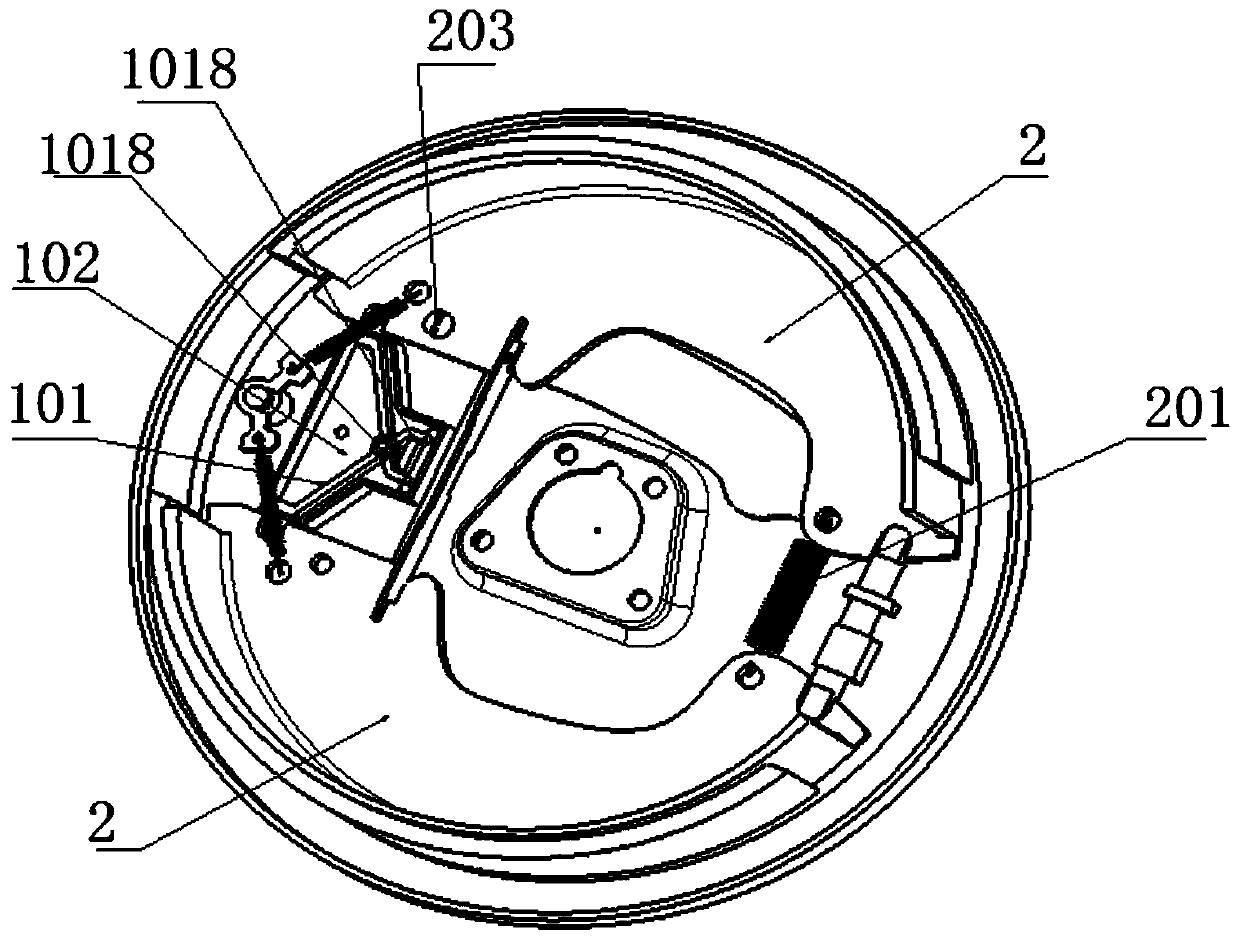

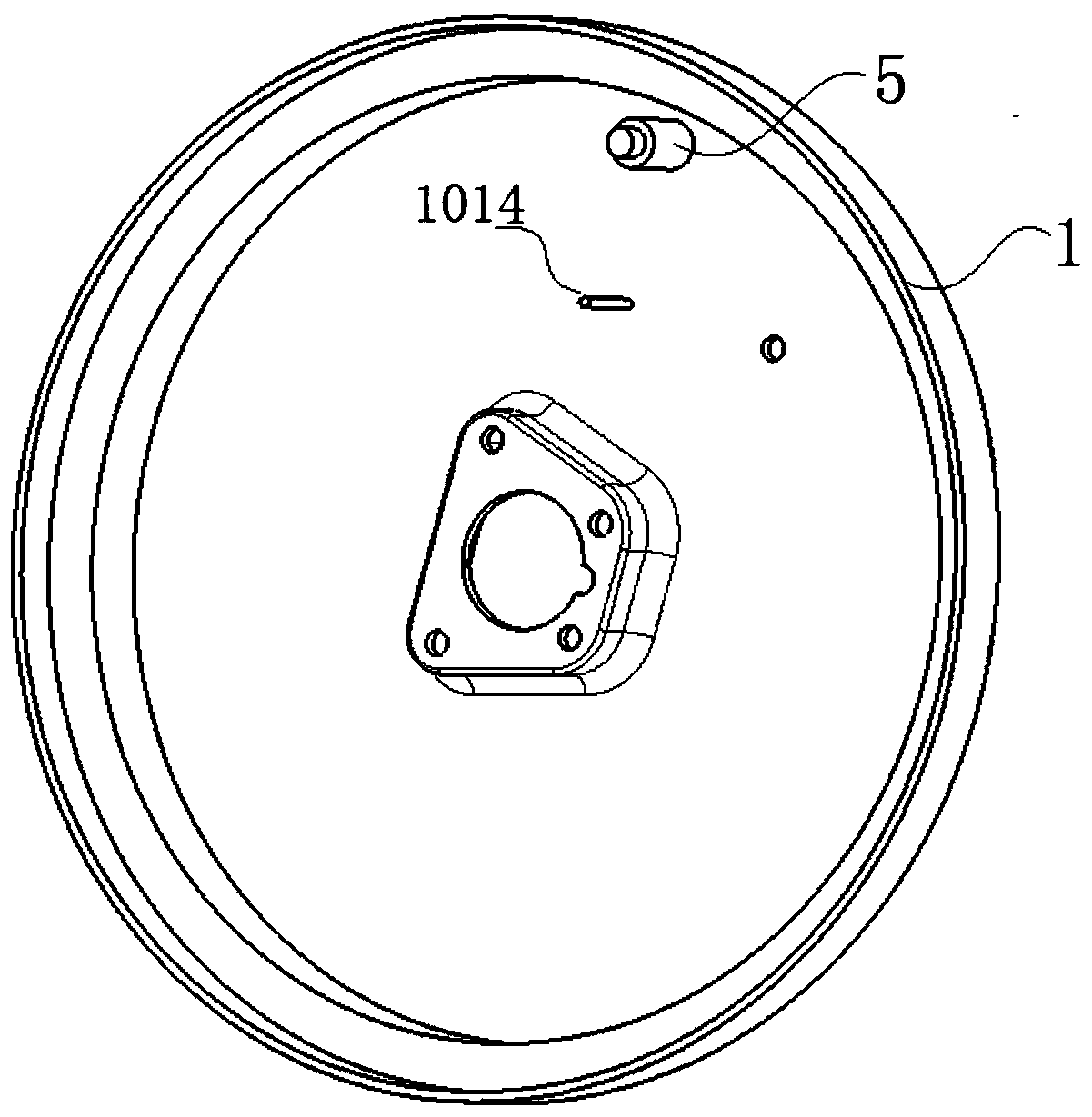

[0027] Embodiment 1: as Figure 1-5 As shown, a drum brake device for small aircraft described in this embodiment includes a base 1, two brake shoes 2 mounted on the base 1 through floating supports, and one end of the brake shoe 2 is provided with Back-moving spring 3, the outer surface of each brake shoe 2 is pasted with friction plate 4. A rotating bracket 5 is arranged between the two brake shoes 2 . The rotating bracket 5 is fixed on the base 1, and the two sides of the rotating bracket 5 are brake shoes 2, respectively provided with a return spring 3, one end of the returning spring 3 is fixed on the rotating bracket 5, and the other end is connected with a brake shoe 2 , when the brake shoe is displaced under the drive of the drive mechanism, the return spring 3 is used to pull the two brake shoes back to their original positions. A brake drum 6 is sheathed on the periphery of the friction plate 4 , and an adjustable push rod 7 connecting the two brake shoes 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com