A multi-temperature zone and large temperature cross-span heat pump circulation system using ejector efficiency

A circulating system and ejector technology, which is applied in the field of vapor compression heat pump heating, can solve the problems of lack of ejectors, and achieve the effects of avoiding irreversible losses, reducing costs, and increasing suction pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

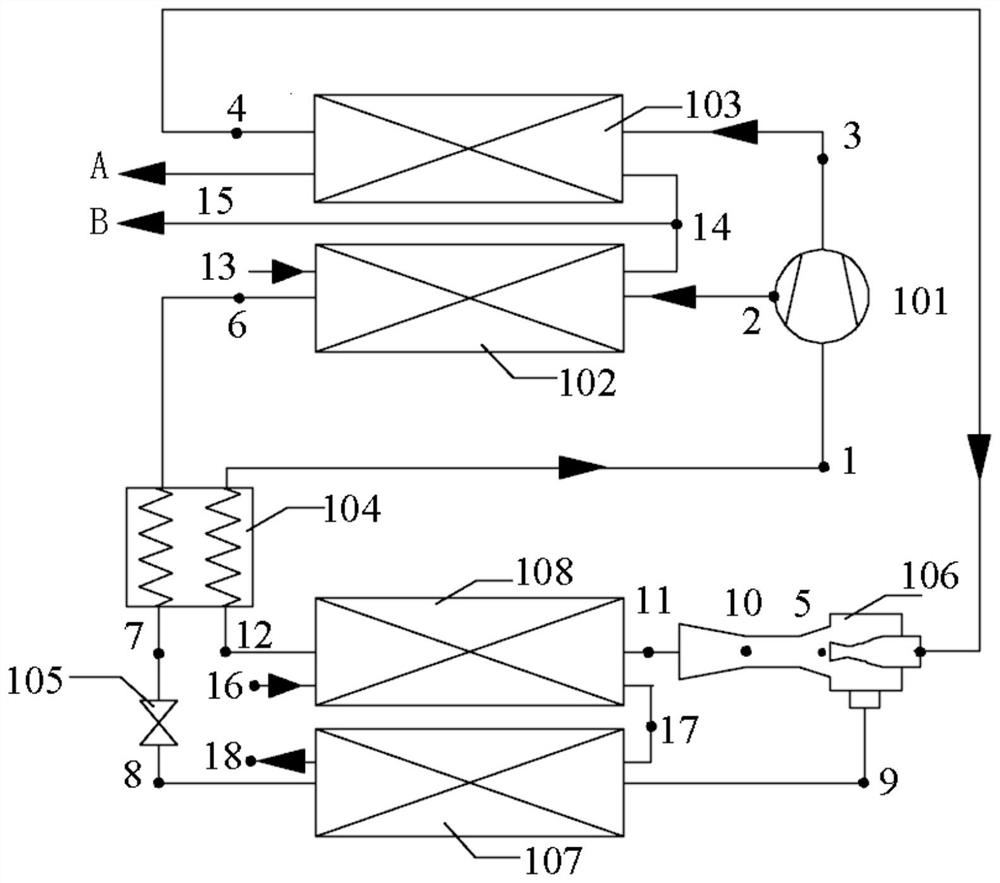

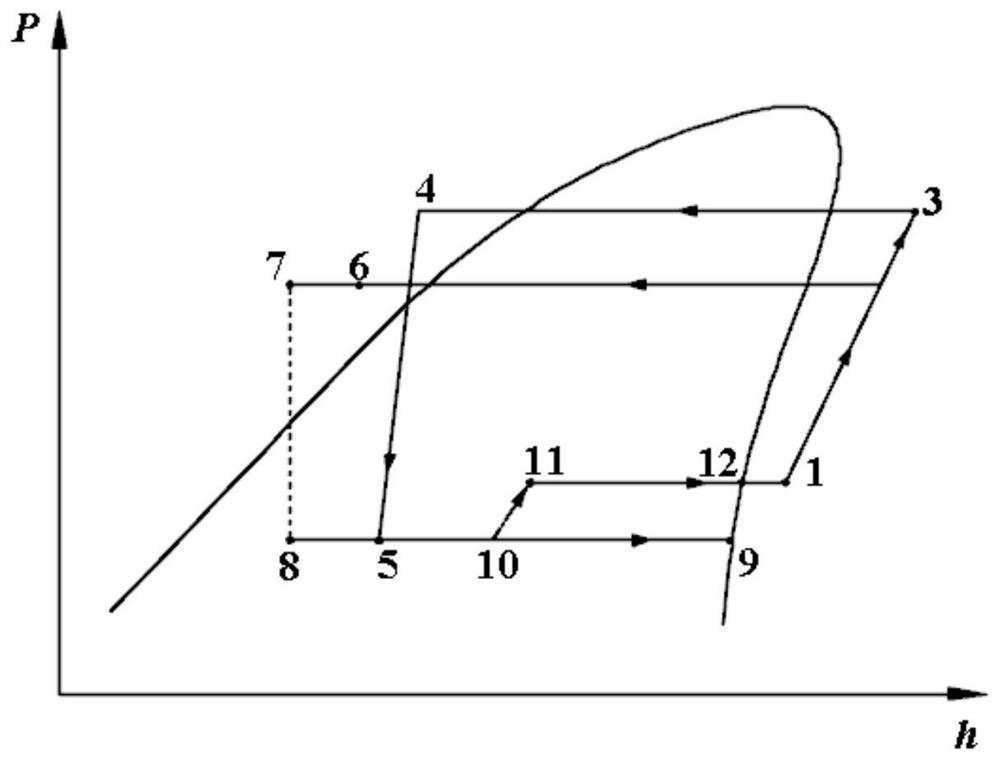

[0028] figure 1Shown is one implementation of the invention. In this embodiment, the compressor 101 with an intermediate air extraction function is an intermediate air extraction compressor, and its types include rolling rotor compressors, screw compressors, scroll compressors and other new compressors with an air extraction function. The intermediate air extraction port of the compressor 101 with intermediate air extraction function is connected to the inlet of the first condenser 102, and the outlet of the first condenser 102 is connected to the inlet of the high pressure side of the regenerator 104; the outlet of the high pressure side of the regenerator 104 is connected to the throttling device 105 in turn It is connected with the inlet of the first evaporator 107; the outlet of the first evaporator 107 is connected with the secondary flow inlet of the injector 106, that is, the injection fluid inlet; the high-pressure exhaust port of the compressor 101 with the intermedia...

Embodiment 2

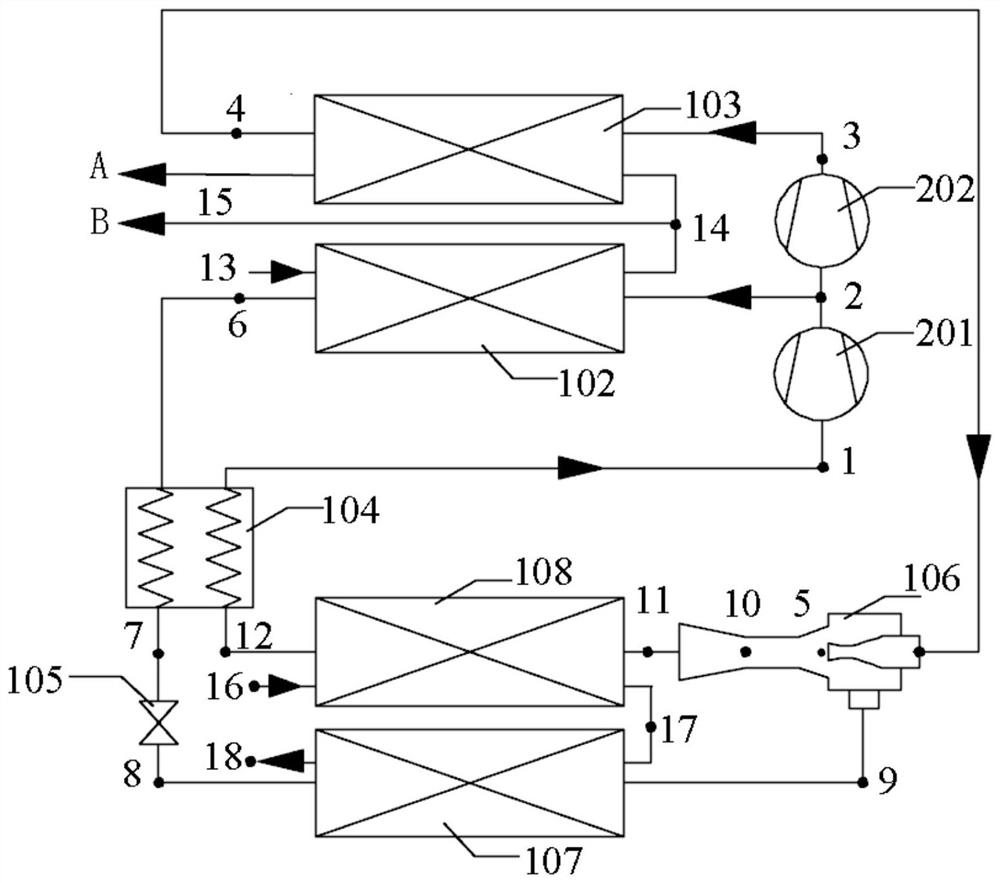

[0031] image 3 Shown is another implementation of the invention. In this embodiment, the multi-temperature zone and large temperature span heat pump system using ejector synergy includes a first-stage series compressor 201 and a second-stage series compressor 202 arranged in series, and the exhaust port of the first-stage series compressor 201 is connected to the The inlet of the first condenser 102 is connected with the inlet of the second-stage series compressor 202, the outlet of the first condenser 102 is connected with the inlet of the high pressure side of the regenerator 104; the outlet of the high pressure side of the regenerator 104 is connected with the throttling device 105 and the first The inlet of the evaporator 107 is connected; the outlet of the first evaporator 107 is connected with the secondary flow inlet of the injector 106, that is, the injection fluid inlet; the exhaust port of the second stage series compressor 202 is connected with the inlet of the sec...

Embodiment 3

[0033] Figure 4 Shown is another implementation of the invention. In this embodiment, the multi-temperature zone and large temperature span heat pump system using ejector synergy includes a parallel low exhaust pressure compressor 301 and a second-stage parallel compressor 302, and the exhaust port of the low exhaust pressure compressor 301 is connected to the The inlet of the first condenser 102 is connected, and the outlet of the first condenser 102 is connected with the inlet of the high-pressure side of the regenerator 104; the outlet of the high-pressure side of the regenerator 104 is connected with the throttle device 105 and the inlet of the first evaporator 107 in turn; The outlet of the device 107 is connected with the secondary flow inlet of the ejector 106, that is, the injection fluid inlet; the outlet of the high discharge pressure compressor 302 is connected with the inlet of the second condenser 103; the outlet of the second condenser 103 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com