Foreign object damage notch calibration method with stress concentration coefficient not smaller than 3

A technology of stress concentration factor and calibration method, which is applied in the testing of mechanical parts, electrical digital data processing, biological neural network model, etc., can solve the error of blade anti-FOD assessment results, damage stress concentration factor, and affect blade anti-FOD design. Work and other issues to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

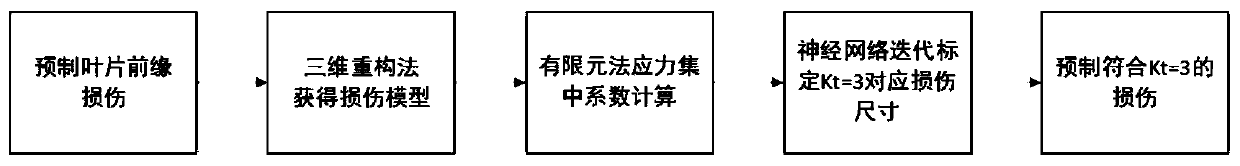

[0016] Please combine figure 1 As shown, the present invention discloses a method for calibrating the foreign object damage notch that ensures that the stress concentration factor (Kt) is not less than 3, comprising the following steps:

[0017] (1) Prefabrication of damage to the leading edge of the blade: use the air cannon method or the machining notch method to prefabricate the FOD damage on the leading edge of the aeroengine blade, that is, the projectile fired by the air cannon hits the leading edge of the aeroengine blade test piece to cause FOD damage; or use Machining machined a damage notch on the leading edge of the aero-engine blade test piece as FOD damage. The basic structure of the air cannon can refer to the Chinese invention patent application with the publication number 110160728A or the Chinese invention patent with the announcement number 103512423B, including a speed measuring device, a cylinder, a gun barrel connected to the cylinder, and a bullet holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com