Micro-led array device based on Group III nitride semiconductor and its preparation method

A technology of nitride semiconductors and arrays, applied in semiconductor devices, electrical solid devices, electrical components, etc., can solve optical crosstalk, can not solve optical crosstalk, and silver cannot be used as electrodes, etc., to improve luminous efficiency and increase current expansion range , Solve the effect of mutual crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation method of the Micro-LED array device based on III-nitride semiconductor with barrier added, the steps include:

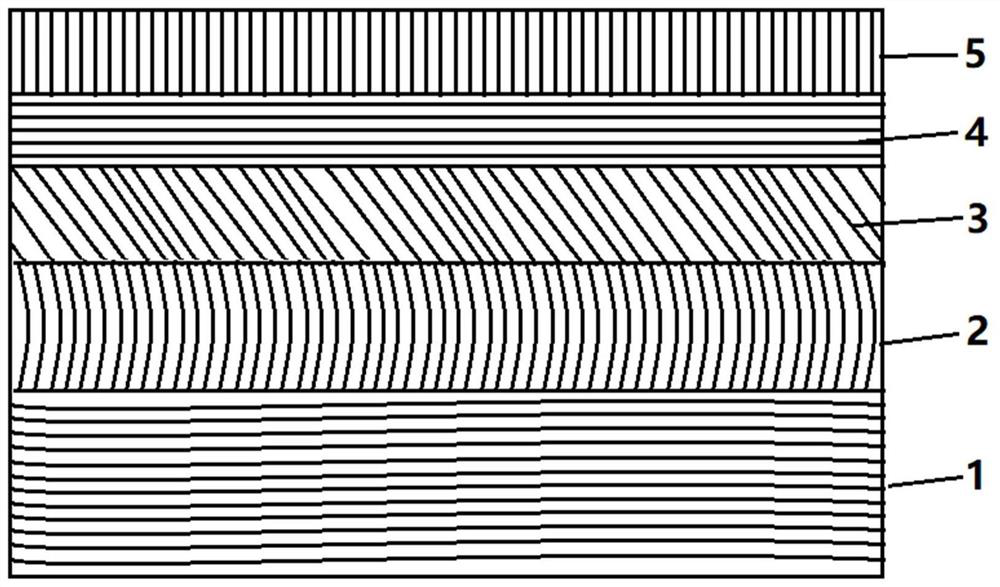

[0055] This method is processed on the Si blue light LED epitaxial wafer, and the structure of the Si blue light LED epitaxial wafer is:

[0056] A Si substrate 1 with a thickness of 800 μm;

[0057] A GaN buffer layer 2 grown on the Si substrate, with a thickness of 1750nm;

[0058] An n-type GaN layer 3 grown on the buffer layer with a thickness of 1650nm;

[0059] An InGaN / GaN quantum well active layer 4 grown on an n-type GaN layer; the thickness of the InGaN / GaN quantum well active layer is 200nm, the number of periods is 10, the In content is 0.26, the Ga content is 0.74, and the well width is 2.2nm, the barrier thickness is 5.8nm;

[0060] A p-type GaN layer 5 grown on the quantum well active layer with a thickness of 100 nm.

[0061] (1) Using PECVD (Plasma Enhanced Chemical Vapor Deposition) technology to evaporate a layer of 150n...

Embodiment 2

[0072] The preparation method of the Micro-LED array device based on III-nitride semiconductor with barrier added, the steps include:

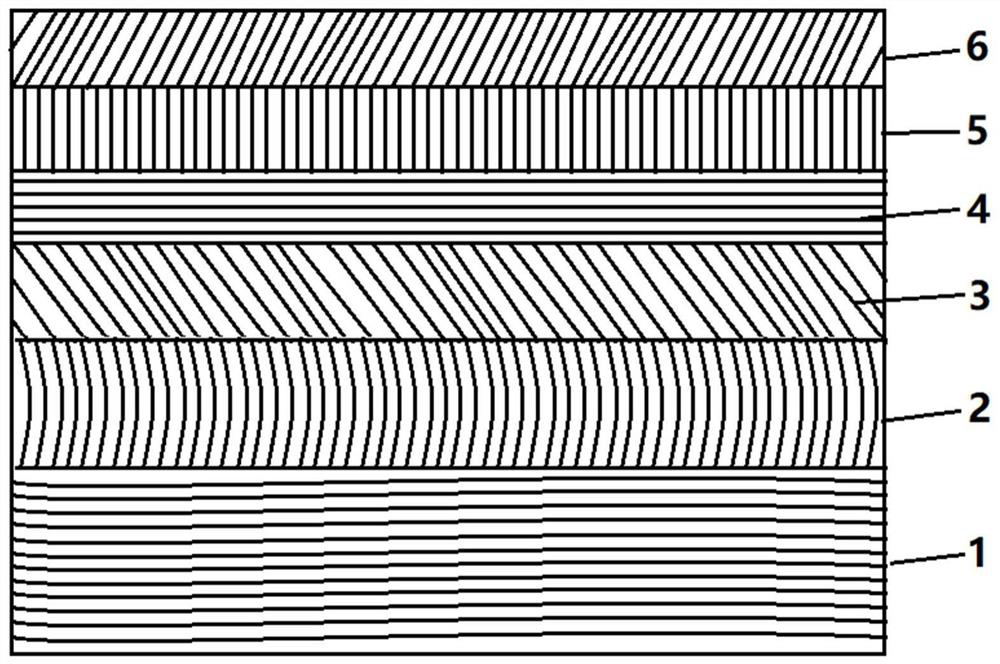

[0073] This method is processed on the Si blue light LED epitaxial wafer, and the structure of the Si blue light LED epitaxial wafer is:

[0074] A Si substrate 1 with a thickness of 800 μm;

[0075] A GaN buffer layer 2 grown on the Si substrate, with a thickness of 1750nm;

[0076] An n-type GaN layer 3 grown on the buffer layer with a thickness of 1750nm;

[0077] An InGaN / GaN quantum well active layer 4 grown on an n-type GaN layer; the thickness of the InGaN / GaN quantum well active layer is 250nm, the number of periods is 10, the In content is 0.26, the Ga content is 0.74, and the well width is 2.2nm, the barrier thickness is 5.8nm;

[0078] A p-type GaN layer 5 grown on the quantum well active layer with a thickness of 150nm.

[0079] (1) Using PECVD (plasma enhanced chemical vapor deposition) technology to evaporate a layer of 200nm t...

Embodiment 3

[0090] The preparation method of the Micro-LED array device based on III-nitride semiconductor with barrier added, the steps include:

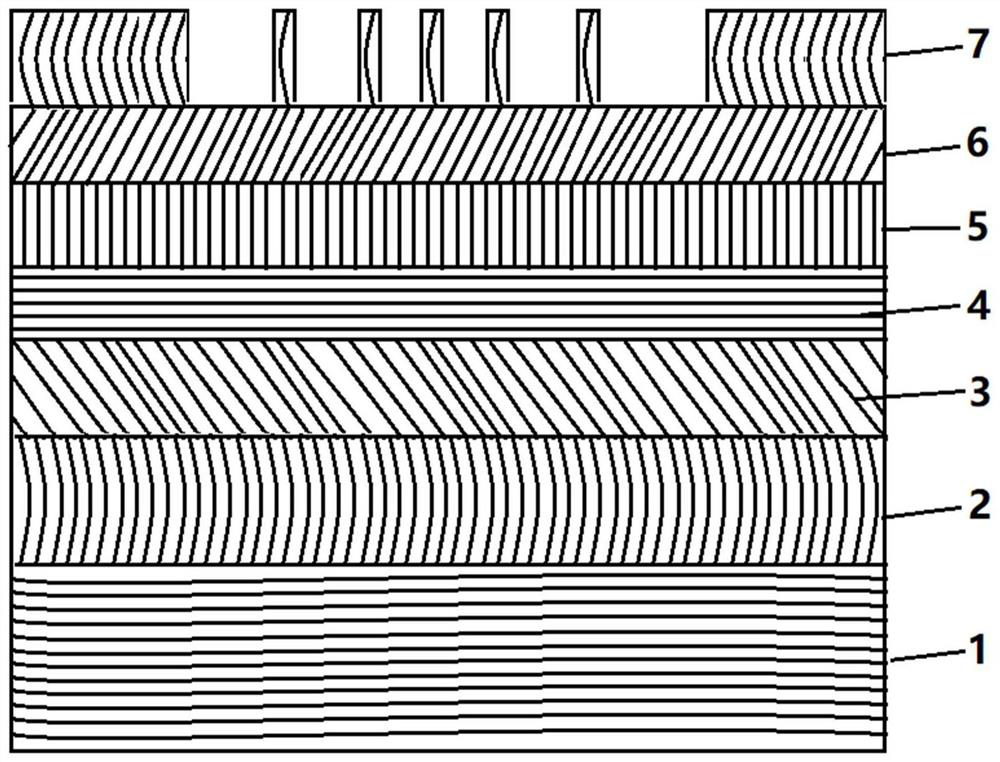

[0091] This method is processed on the Si blue light LED epitaxial wafer, and the structure of the Si blue light LED epitaxial wafer is:

[0092] A Si substrate 1 with a thickness of 800 μm;

[0093] A GaN buffer layer 2 grown on the Si substrate, with a thickness of 1750nm;

[0094] An n-type GaN layer 3 grown on the buffer layer with a thickness of 1850nm;

[0095] An InGaN / GaN quantum well active layer 4 grown on an n-type GaN layer; the thickness of the InGaN / GaN quantum well active layer is 300nm, the number of periods is 10, the In content is 0.26, the Ga content is 0.74, and the well width is 2.2nm, the barrier thickness is 5.8nm;

[0096] A p-type GaN layer 5 grown on the quantum well active layer with a thickness of 200nm.

[0097] (1) Using PECVD (plasma enhanced chemical vapor deposition) technology to evaporate a layer of 250nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com