A flexible integrated array pressure sensor and preparation method thereof

A pressure sensor, integrated technology, applied in the field of flexible sensors, to achieve the effects of increased sensitivity, increased resistance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

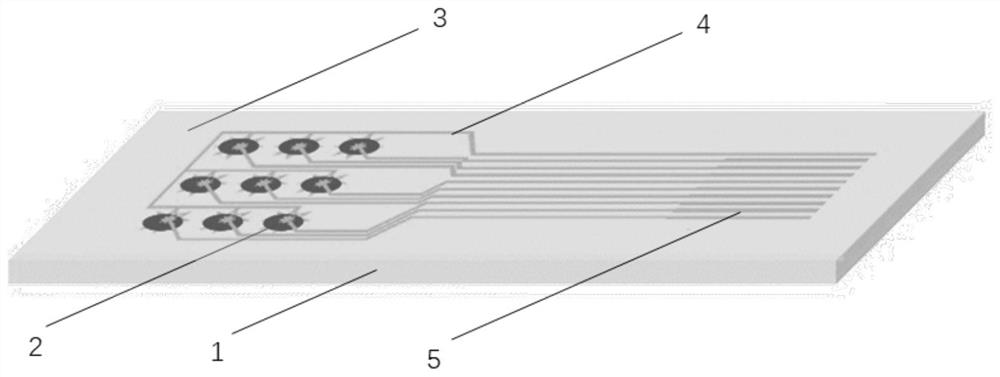

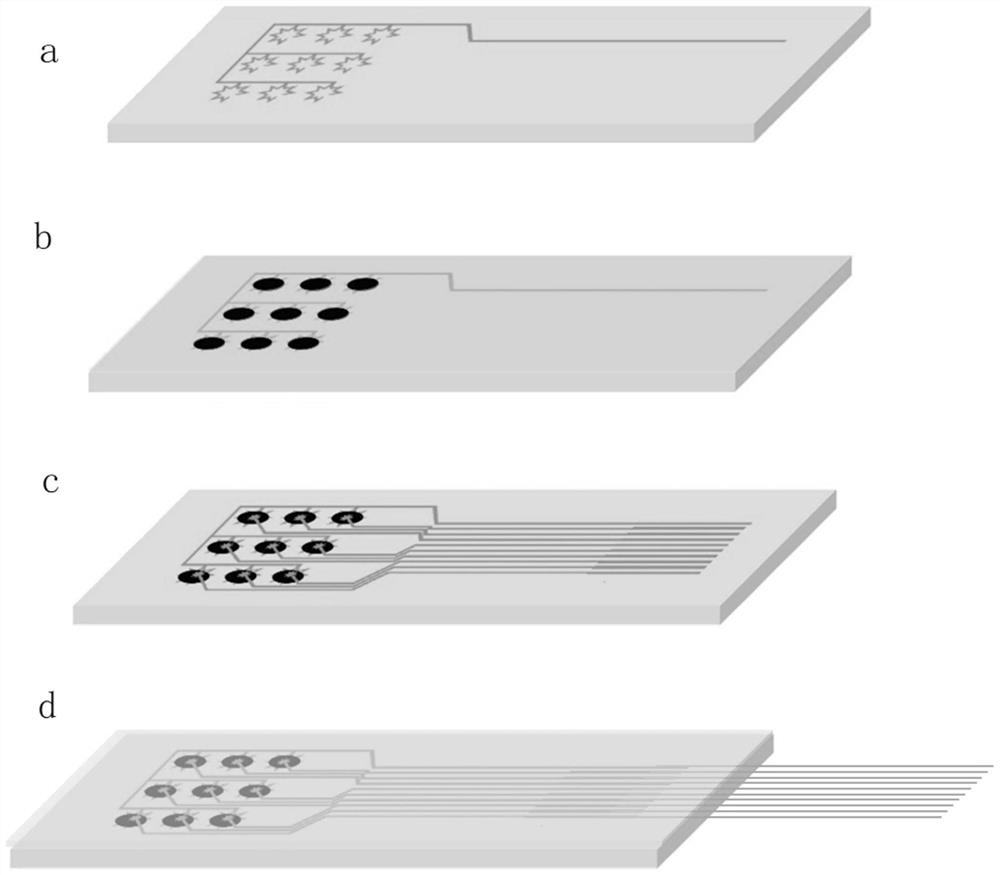

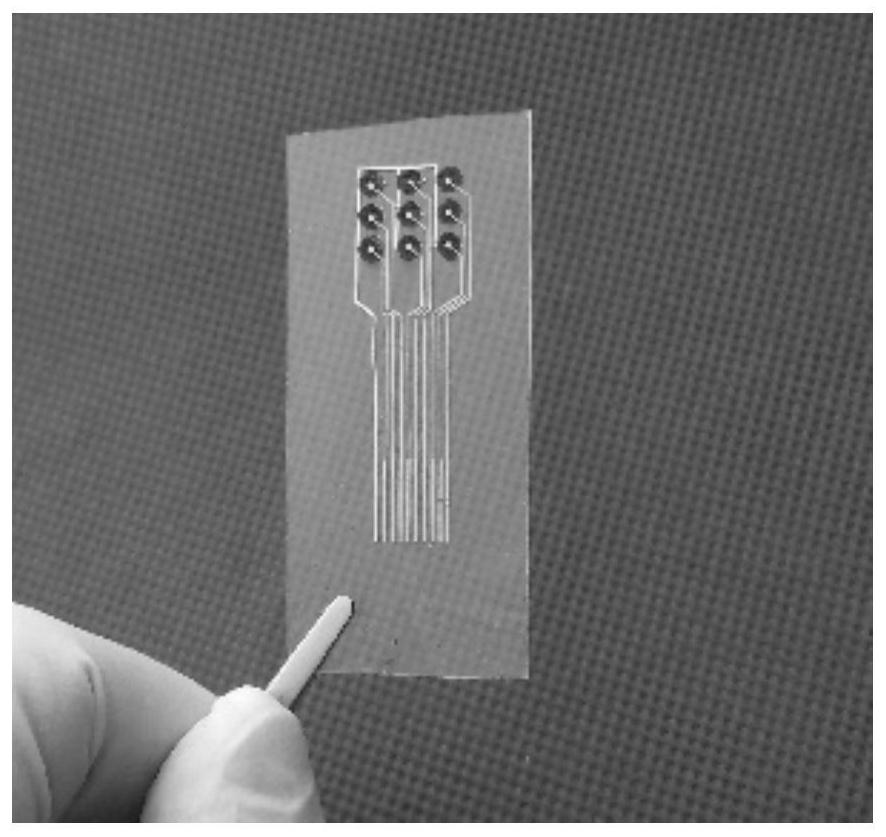

[0052] A preparation method of a flexible integrated array pressure sensor, the flow chart of the design method is shown in figure 2 , the specific steps are:

[0053] 1) Fabrication of flexible arrayed electrodes

[0054] 1.1) A flexible arrayed electrode pair is prepared by laser direct writing on a flexible substrate, including a flexible arrayed upper electrode and a flexible arrayed lower electrode. After etching, a miniature copper electrode that can be transferred twice is obtained. The material of the flexible substrate is poly Dimethyl siloxane, this process results in a flexible structure processed in one pass;

[0055] 1.2) Use absolute ethanol to clean the surface of the flexible arrayed electrode, and transfer the flexible arrayed lower electrode to the surface of the polydimethylsiloxane film for a second time.

[0056] 2) Preparation of flexible array integrated pressure sensing module

[0057] 2.1) Prepare patterned copper foil mask by laser direct writing ...

Embodiment 2

[0066] A preparation method of a flexible integrated array pressure sensor, the specific steps are:

[0067] 1) Fabrication of flexible arrayed electrodes

[0068] 1.1) A flexible arrayed electrode pair is prepared on a flexible substrate by a laser direct writing method, including a flexible arrayed upper electrode and a flexible arrayed lower electrode. After etching, a micro silver foil electrode that can be transferred twice is obtained. The material of the flexible substrate is Acrylic, this process results in a flexible structure processed in one go;

[0069] 1.2) Use absolute ethanol to clean the surface of the flexible arrayed electrode, and transfer the lower electrode of the flexible array to the surface of polydimethylsiloxane twice.

[0070] 2) Preparation of flexible array integrated pressure sensing module

[0071] 2.1) Spin-coat the conductive carbon oil to form a thin film and cure it at room temperature, pattern the thin film by laser direct writing, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com