Low-pulsating-torque switched reluctance motor and driving method thereof

A pulsating torque and switched reluctance technology, applied in motor control, AC motor control, torque pulsation control, etc., can solve problems affecting the wide application of motors, and achieve the effect of reducing pulsating torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

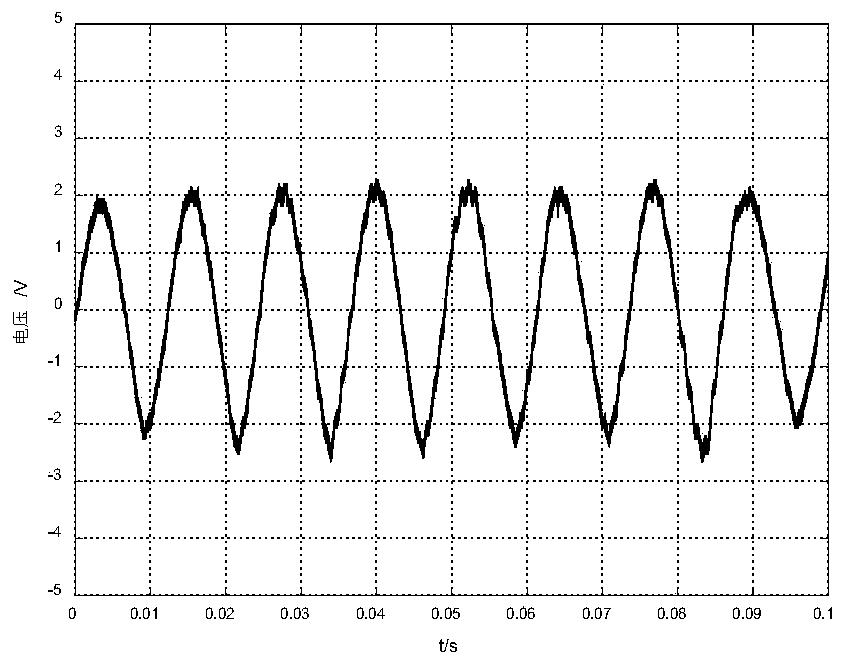

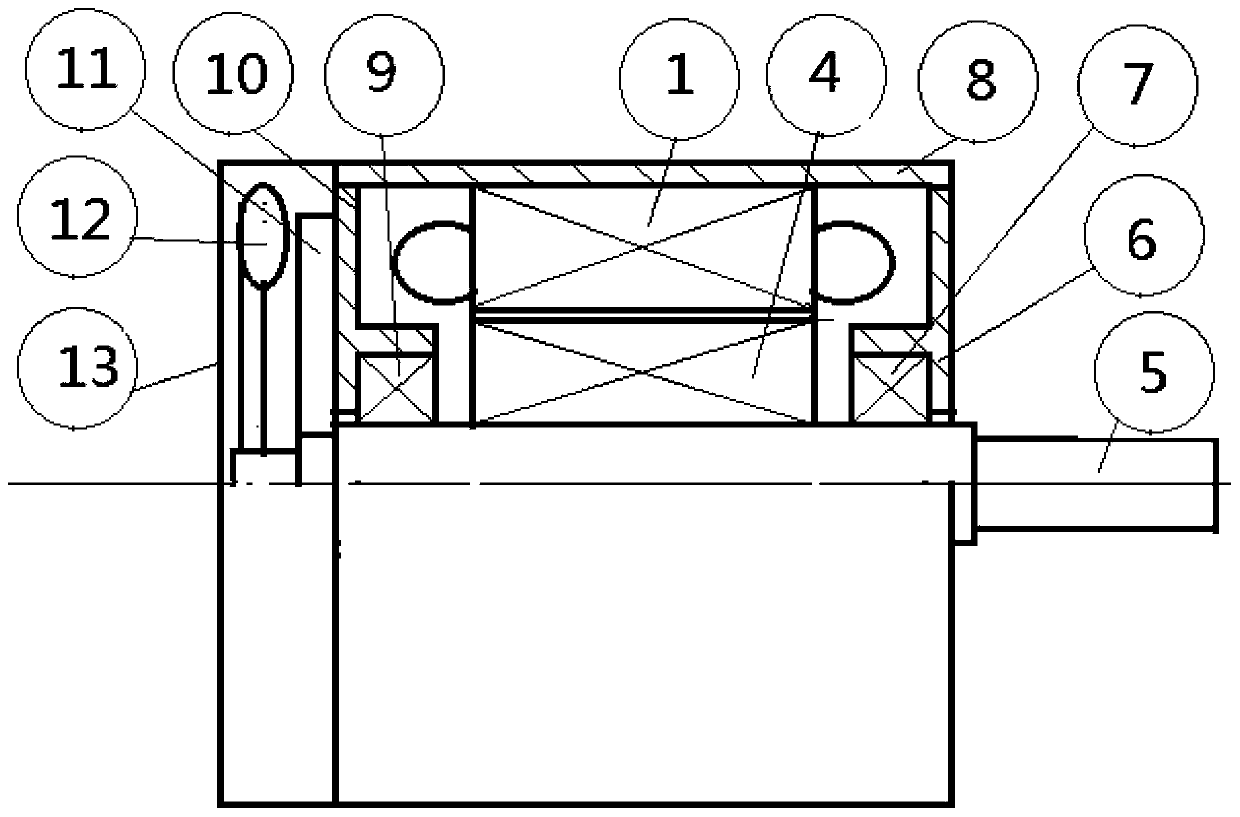

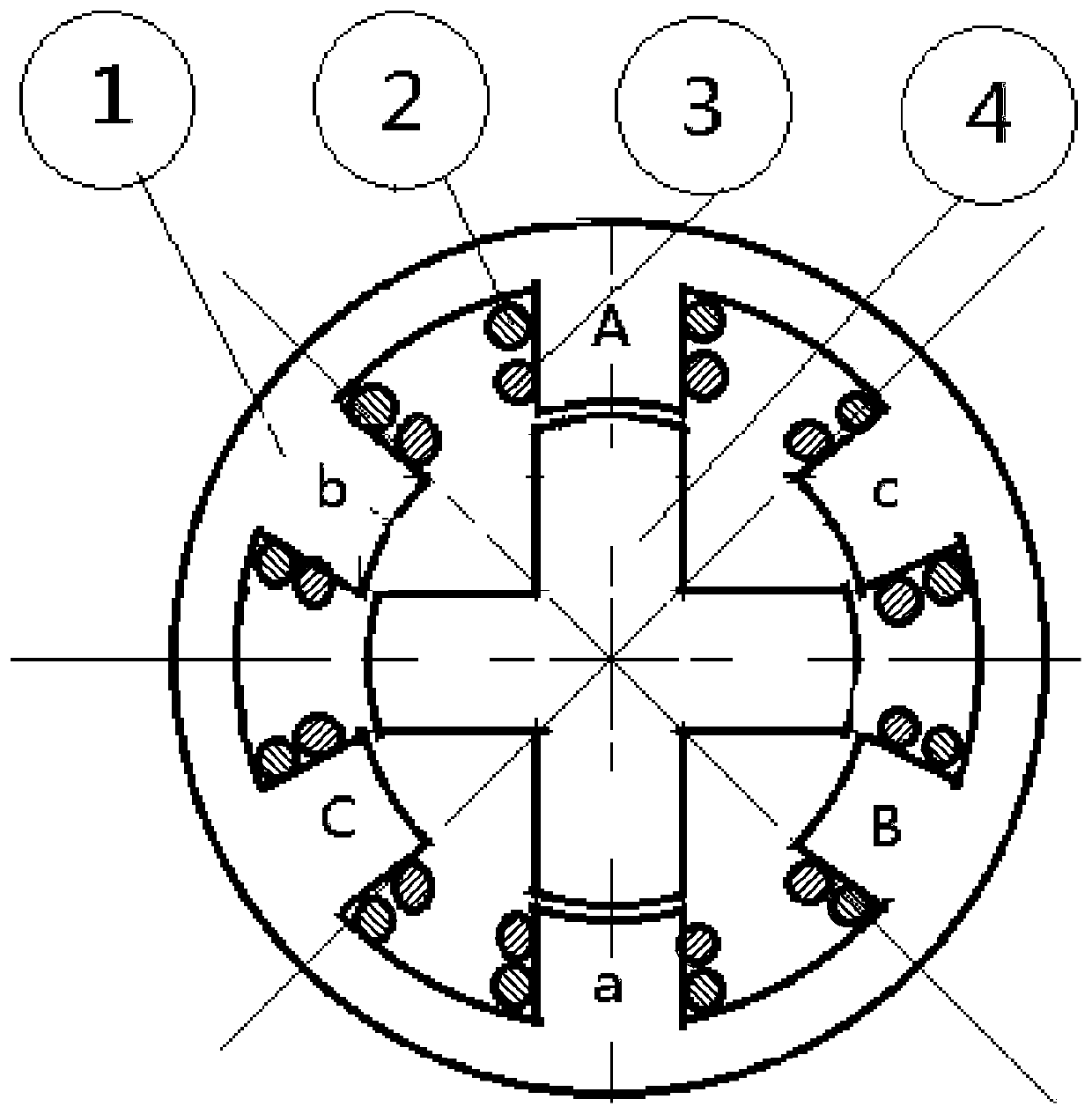

[0027] Such as figure 2 , 3 As shown in and 4, a switched reluctance motor with low pulsating torque includes a stator core 1, a first winding 2, a second winding 3, a rotor core 4, a rotating shaft 5, a front end cover 6, a front end cover bearing 7, and a base 8. Rear end cover bearing 9, rear end cover 10, position sensor 11, cooling fan 12, fan cover 13 and speed control system. The two ends of the front end cover 6, the rear end cover 10 and the machine base 8 are respectively fixed. The outer rings of the front end cover bearing 7 and the rear end cover bearing 9 are respectively embedded in the middle parts of the inner surfaces of the front end cover 6 and the rear end cover 10 . Both ends of the rotating shaft 5 are respectively embedded in the inner rings of the front end cover bearing 7 and the rear end cover bearing 9 . The stator core 1 is fixed inside the base 8 . The rotor core 4 is fixed on the rotating shaft 5 and located inside the stator core 1 . The r...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that: the number of pole pairs of the stator core 1 and the rotor core 4 is n; n is not limited to 1. The tooth-to-slot ratio of the stator core 1 and the rotor core 4 (that is, the tooth ratio of the stator-rotor core) is 6n:4n. There are a total of 6n slots on the stator core 1 . The 6n alveoli are divided into n alveolar groups in groups of six. The six slots in the same slot group are evenly distributed along the circumferential direction of the central axis of the stator core 1 . The n slot groups are sequentially staggered along the circumferential direction of the central axis of the stator core 1

[0051] A first winding 2 and a second winding 3 are wound on each of the n slot groups of the stator core 1 . Both the first winding 2 and the second winding 3 are symmetrical three-phase windings with the same parameters. The 6 alveoli in the same group are respectively defined as tooth A, tooth B, toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com