A multi-station cycle operation conditioning and dehydration device

A technology of circulation operation and dehydration device, which is applied to the feeding/discharging device of the settling tank, dehydration/drying/thickened sludge treatment, separation method, etc., which can solve the problems of increasing labor level and reducing sludge dehydration speed, etc. , to achieve the effect of reducing the difficulty of cleaning, reducing the difficulty of adding precipitant, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

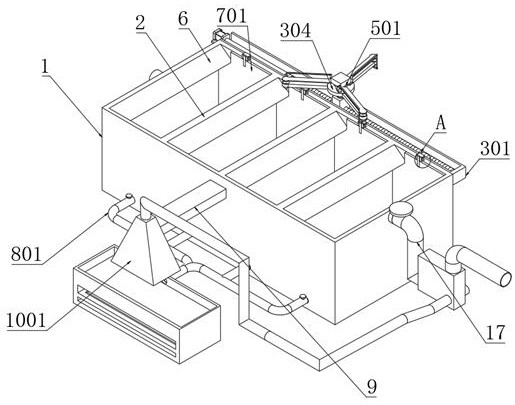

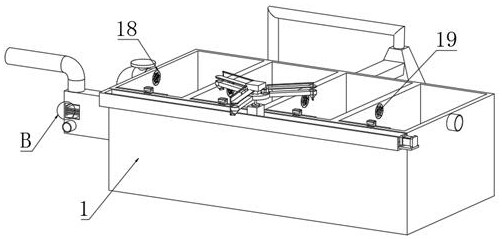

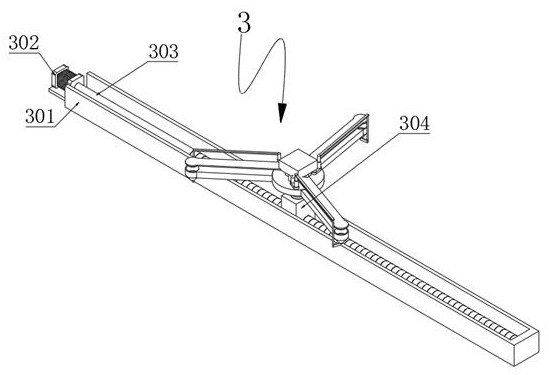

[0051] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, a multi-station cycle operation conditioning and dehydration device, including a settling tank 1, a partition plate 2 is equidistantly installed in the middle of the inner wall of the settling tank 1, and a synchronous Moving mechanism 3, synchronous moving mechanism 3 comprises concave rod 301, linear reciprocating motor 302, screw mandrel 303, moving block 304, rotating motor 305, rotating disk 306, cross bar 307, tapered bucket 308, accumulator 309, electric telescopic rod 310 and connecting rod 311;

[0052] A concave rod 301 is installed on the back side of the settling tank 1, and a linear reciprocating motor 302 is installed on one end of the concave rod 301, and a screw rod 303 is clamped on one end of the linear reciprocating motor 302, and a moving rod 303 is socketed on the outer surface of the screw rod 303. Block 304, the middle part of the top of the moving block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com