Asymmetric membrane with pore size, preparation method, and application in seawater desalination

An asymmetric and diaphragm technology, applied in seawater treatment, chemical instruments and methods, membranes, etc., can solve the problem of no polyolefin diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

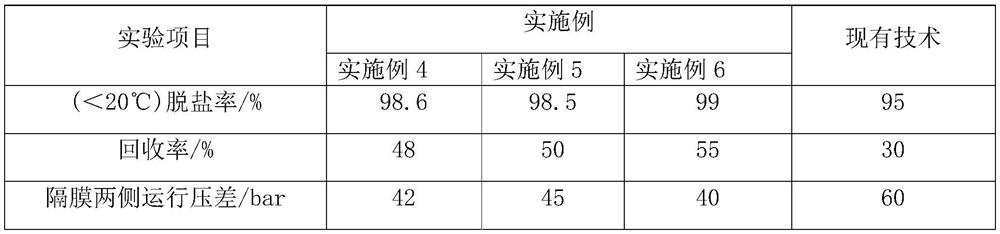

Examples

Embodiment 1

[0021] The asymmetric pore diameter diaphragm of the present embodiment 1 includes: a diaphragm distributed with multi-layer microporous structures; wherein the microporous structures on the upper and lower surface layers of the diaphragm have unequal pore diameters.

[0022] Optionally, the pore diameters of the microporous structures of the upper surface layer 1, the middle layer 2, and the lower surface layer 3 of the membrane are 100-200 nm, 70-100 nm, and 10-40 nm in sequence. Optionally, the pore diameters of the microporous structures of the upper surface layer, the middle layer, and the lower surface layer of the membrane are 140 nm, 80 nm, and 25 nm in sequence.

[0023] Optionally, the thickness ratio of the upper surface layer, the middle layer, and the lower surface layer of the diaphragm is 1 / 4:1 / 2:1 / 4 in turn, and the macroporous structure of the upper surface layer of the diaphragm blocks macromolecular impurities and bacteria in seawater , the micropores in the...

Embodiment 2

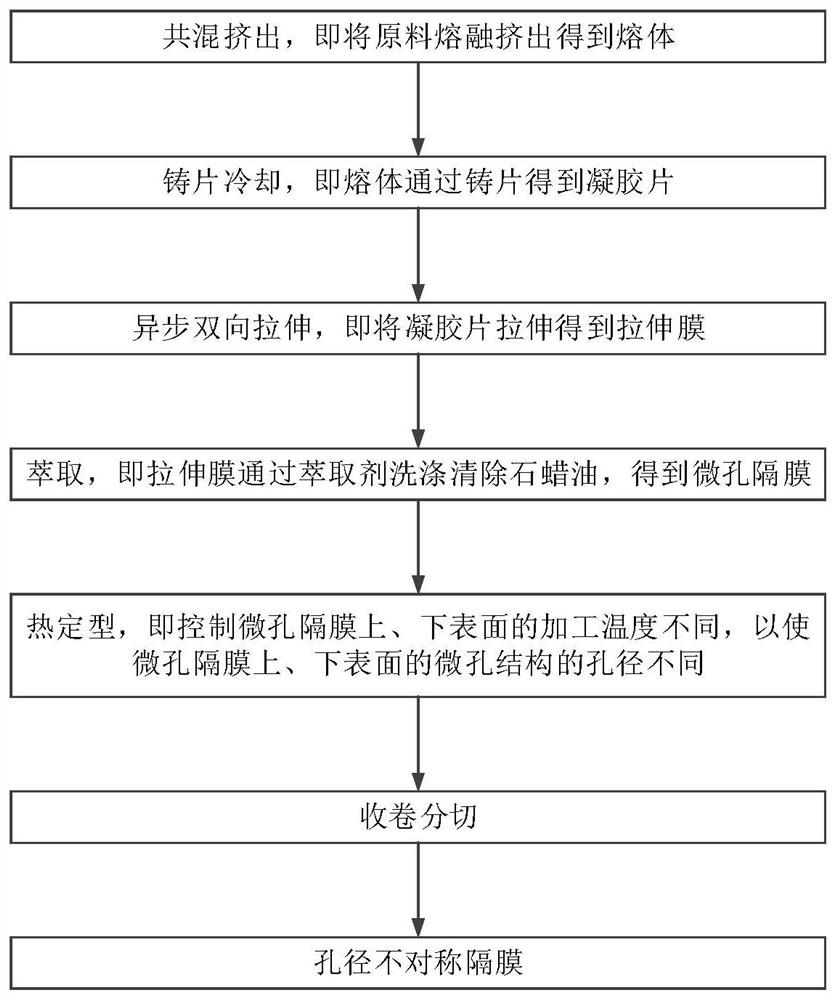

[0026] See figure 1 , on the basis of Example 1, this Example 2 also provides a method for preparing a diaphragm with an asymmetric pore size, including: blending and extruding, that is, melting and extruding the raw materials to obtain a melt; casting sheet cooling, that is, passing the melt through Cast sheet to obtain gel sheet; asynchronous biaxial stretching, that is, stretching the gel sheet to obtain a stretched film; extraction, that is, the stretched film is washed with an extractant to remove paraffin oil, and a microporous diaphragm is obtained; heat setting, that is, to control the microporous diaphragm The processing temperature of the upper and lower surfaces is different, so that the pore diameters of the microporous structures on the upper and lower surfaces of the microporous diaphragm are different; and winding and cutting to obtain a multilayer microporous diaphragm with asymmetric pore diameters on both sides (ie, asymmetric pore diameter diaphragm) .

[0...

Embodiment 3

[0039] On the basis of embodiment 1 or 2, this embodiment 3 also provides an application of a membrane with asymmetric pore size as a reverse osmosis membrane for seawater desalination.

[0040] Specifically, the upper surface of the diaphragm is distributed with a dense microporous structure of small pore size, and the lower surface of the diaphragm is distributed with a microporous structure of large pore size. When seawater passes through the diaphragm, the microporous structure of the upper surface layer of the diaphragm is suitable for water molecules and dissolved oxygen to pass through smoothly. However, it will cut off impurities, bacteria and macromolecular salts (diameter > 10nm) in seawater, and obtain drinkable fresh water on the lower surface of the diaphragm to achieve seawater desalination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com