A modular test chamber for space material experiment samples

A test chamber and modular technology, applied in the field of aerospace material exposure experiments, can solve problems such as affecting the smooth progress of exposure experiments of other materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

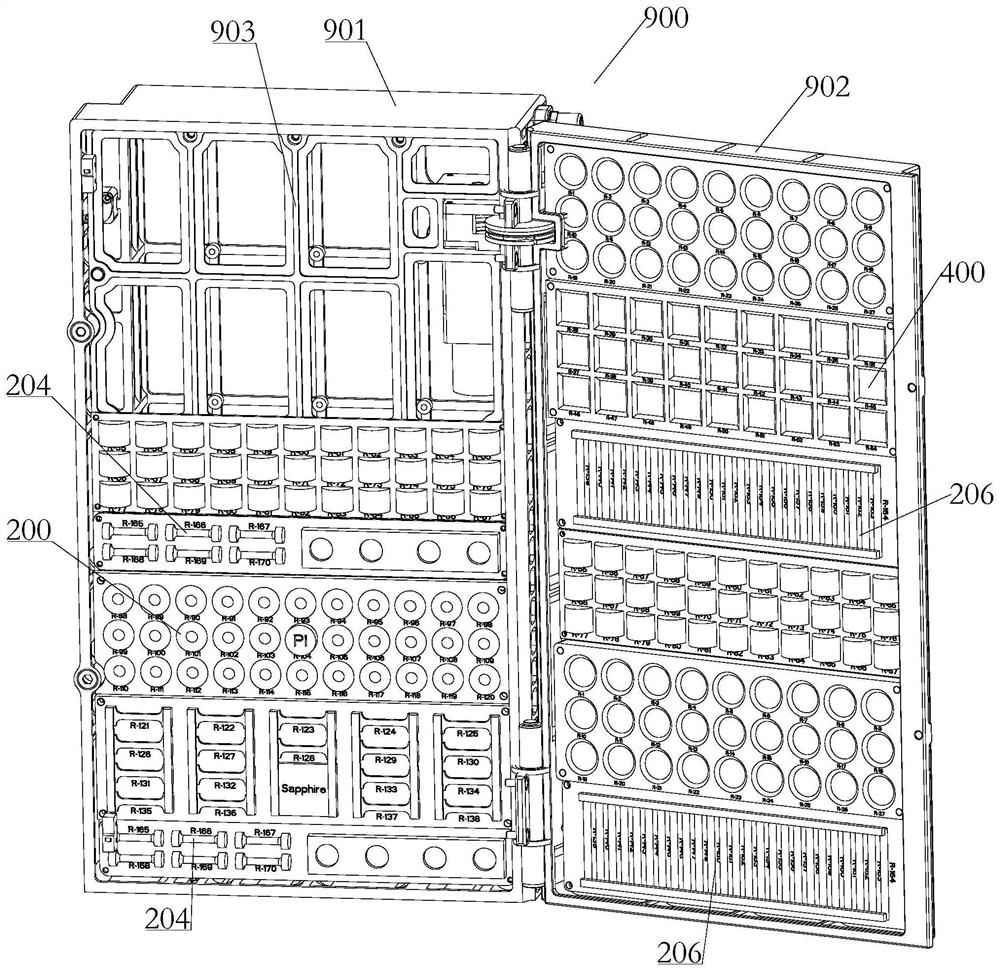

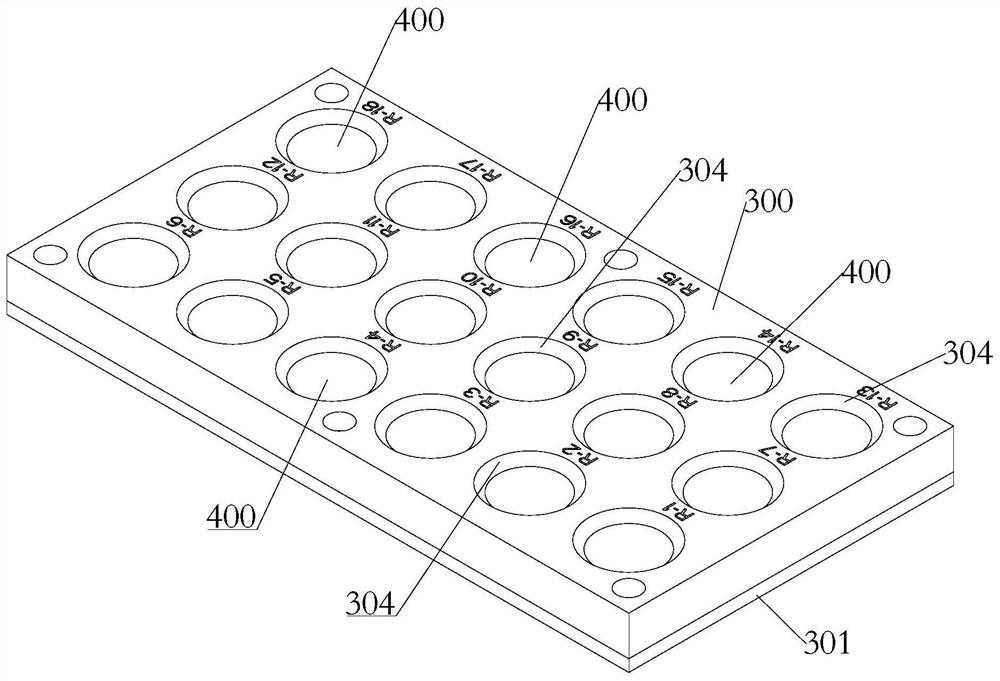

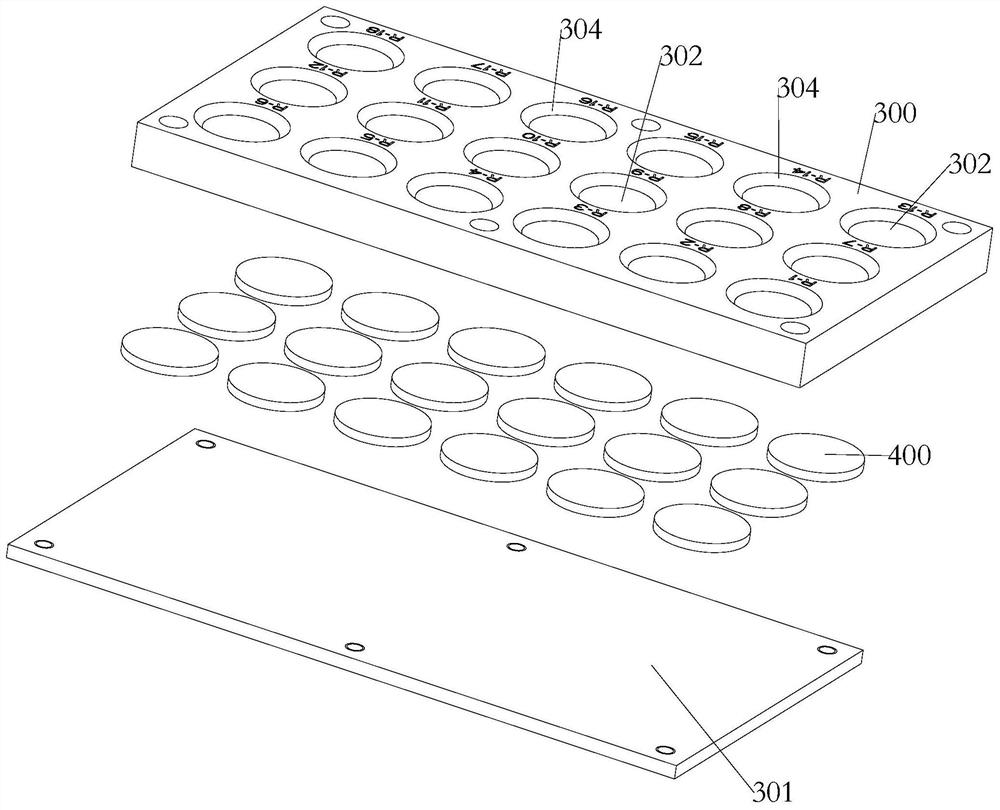

Embodiment 1

[0156] Such as Figure 2-Figure 4 As shown, this embodiment mainly relates to a general material module, the sample material is a general material, the installation support structure includes an upper cover 300 and a lower cover 301, and the upper cover 300 is provided with a number of exposure holes 302, the On the inner ring side of the upper end of the exposure hole 302, there is a circle of crimping edge 303, and the upper end of the crimping edge 303 is provided with a circle of chamfering 304 near the position of the exposing hole 302, and the specific chamfering angle is 45°; the lower cover plate 301 is detachable Installed on the lower end of the upper cover 300 , an installation space for installing materials is formed between the lower cover 301 and the pressing edge 303 .

[0157] Such as Figure 2-Figure 4 As shown, the general material of this embodiment is adapted to be installed in the installation space. The sample module of this embodiment can be used for e...

Embodiment 2

[0159] Such as Figure 5-Figure 8 As shown, the present embodiment mainly involves the functional material module, the sample material is a functional material, the installation support structure includes an upper cover 300 and a lower cover 301, and the upper cover 300 is provided with a number of exposure holes 302, so The upper end of the exposed hole 302 is provided with a circle of bevels 303 on the inner ring side, and the upper end of the bezels 303 is provided with a circle of chamfers 304 near the position of the exposed holes 302, and the specific design of the chamfers is 45°; the lower cover plate 301 can be It is disassembled and installed at the lower end of the upper cover plate 300 , and an installation space for installing materials is formed between the lower cover plate 301 and the pressing edge 303 .

[0160] Such as Figure 5-Figure 8As shown, the installation support structure of this embodiment also includes an O-ring 305, an isolation ring 306 and a su...

Embodiment 3

[0165] Such as Figure 9-Figure 11 As shown, the present embodiment mainly involves polymer material modules, and the installation support structure includes an upper cover plate 300 and a lower cover plate 301, and several exposure holes 302 are opened on the upper cover plate 300, and the upper ends of the exposure holes 302 are A circle of bevel 303 is provided on the inner ring side, and a circle of chamfer 304 is provided at the upper end of the bezel 303 close to the exposure hole 302, and the chamfer is specifically designed to be 45°; the lower cover 301 is detachably mounted on the At the lower end of the upper cover plate 300 , an installation space for installing materials is formed between the lower cover plate 301 and the pressing edge 303 .

[0166] Such as Figure 9-Figure 11 As shown, the installation support structure of this embodiment also includes a spacer plate 308 and an elastic support plate 309, the elastic support plate 309 is located above the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com