Fatigue test device for outer front flap and joint test piece

A fatigue test and test piece technology, applied in the field of aircraft structure fatigue test, to achieve the effect of saving test resources and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

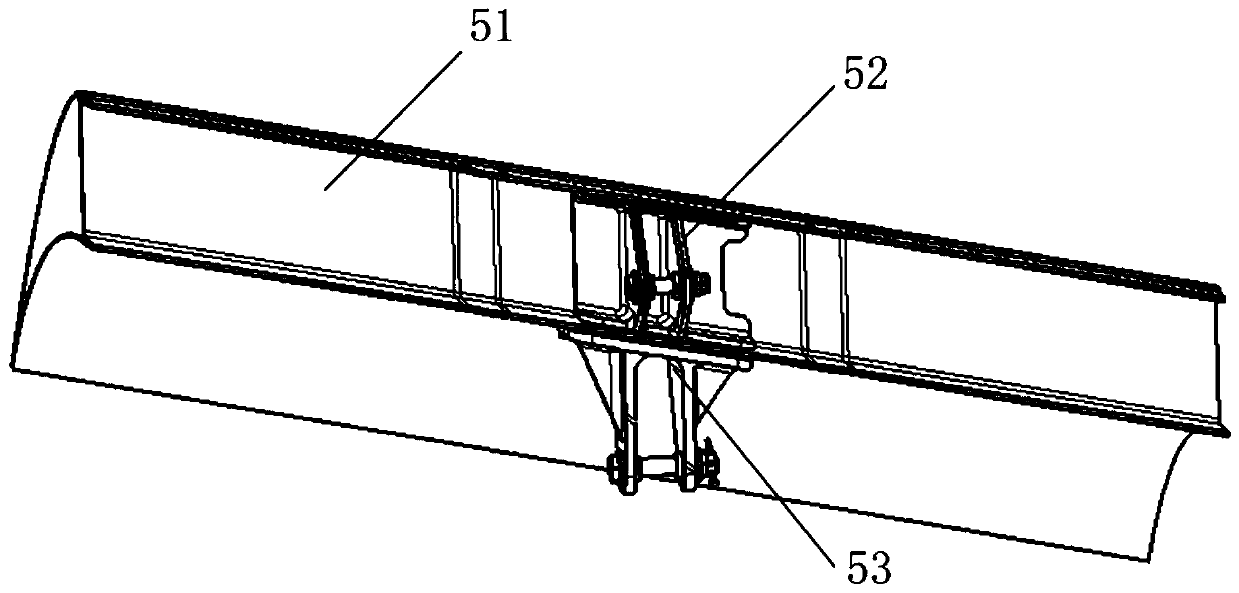

[0034] Such as Figure 1 to Figure 5 As shown, in order to carry out the fatigue test of the outer front flap and the joint, the outer front flap and the joint test piece are constructed at first in the present application, and the said test piece is the same or similar to the real structure, and it is mainly composed of the front flap 51, the front joint 52 and the rear Connector 53 consists of, as figure 2 shown.

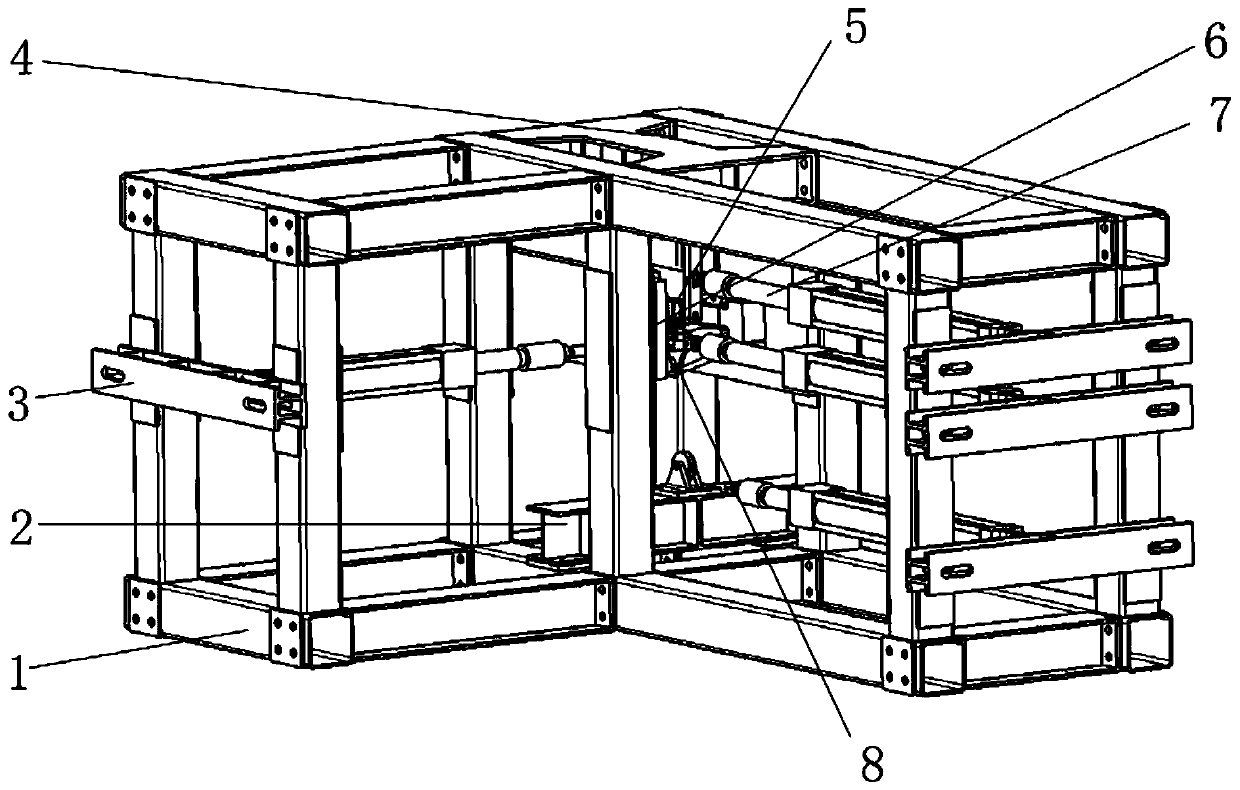

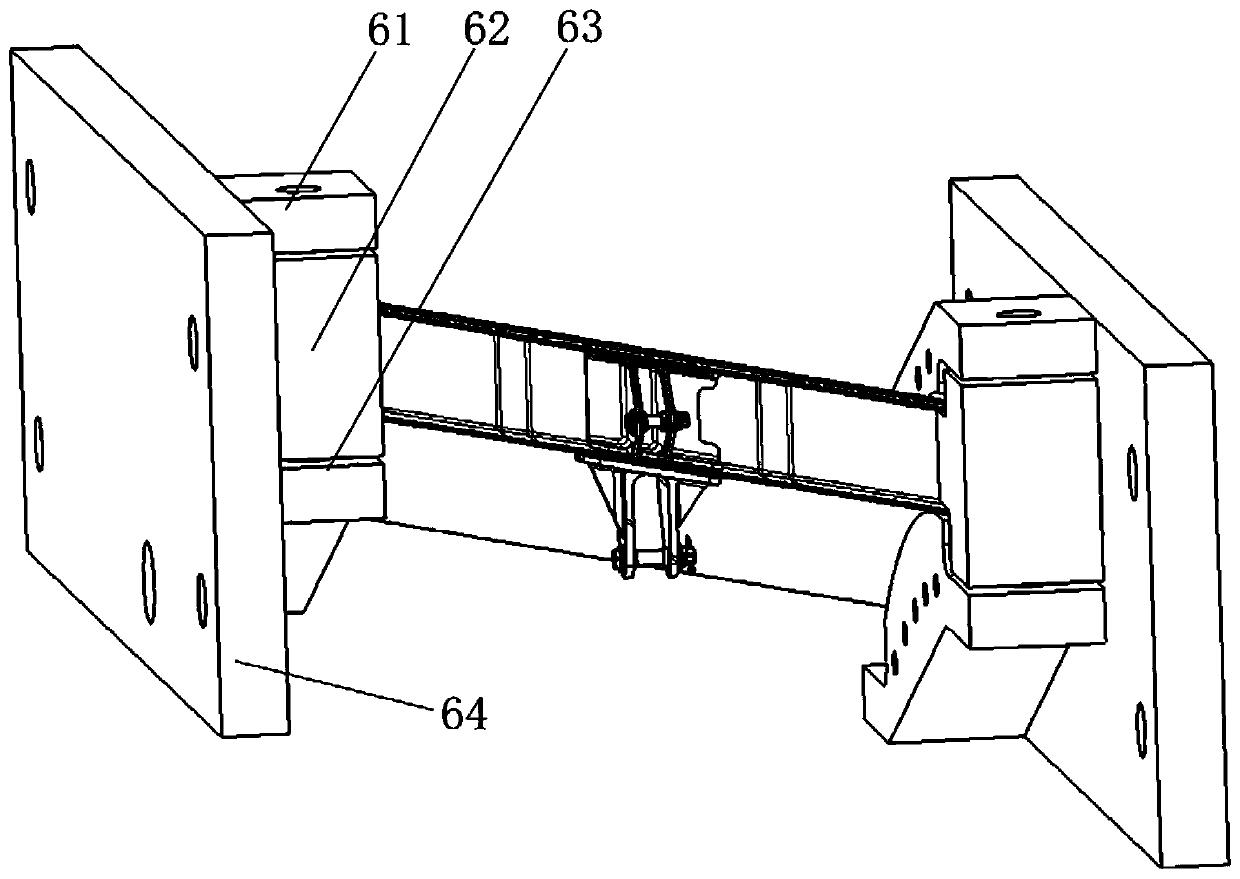

[0035] For this reason, the fatigue test device for the outer front flap and the joint test piece proposed by the application includes: test bench 1, pulley seat assembly support structure 2, actuator fixed beam 3, lever support support structure 4, test piece Support 6, front joint loading m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com