A Refractory Wastewater Treatment System

A wastewater treatment system and technology of the treatment system, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. and treatment cost increase, to achieve the effect of recycling, efficient and stable treatment, and reduction of treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, refractory wastewater treatment system

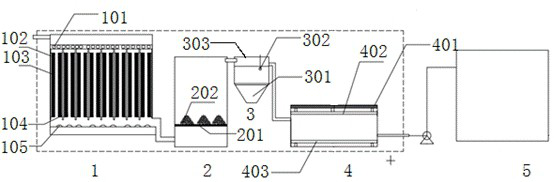

[0041] The structure diagram of the processing system of the present invention is as follows: figure 1 As shown, it includes a regulating tank, a DBD plasma reactor 1, an iron-carbon micro-electrolysis reactor 2, a static sedimentation system 3, a photocatalytic waste water fuel cell system 4, and a nanofiltration-reverse osmosis double-membrane system 5 connected sequentially by pipelines. .

[0042] Wherein, the upper part of the DBD plasma reactor is provided with a water distribution layer, and the water distribution layer is provided with a water distribution hole 101, and the waste water enters the plasma reaction zone in the middle through the water distribution hole in the water distribution layer; The reaction area is equipped with multiple sets of high and low voltage electrode pairs separated by partition plates, forming multiple plasma reaction zones; the distance between the high and low voltage electr...

Embodiment 2

[0047] Embodiment two, refractory wastewater treatment process

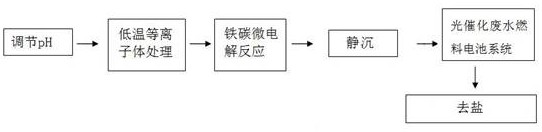

[0048] Using the above system according to figure 2 The technological process treats the wastewater, and the treatment steps are:

[0049] S1, adding sulfuric acid to the waste water to adjust the pH to 4;

[0050] S2. Pass the waste water into the DBD plasma reactor for treatment. The working atmosphere in the DBD plasma reactor is air, the intake flow rate is controlled at 2L / min, and the discharge voltage is controlled at 10kv-30kv;

[0051] S3, passing the effluent of the operation S2 into the iron-carbon micro-electrolysis reactor to carry out the iron-carbon micro-electrolysis reaction; the weight ratio of the iron-based material and the carbon-based material in the iron-carbon micro-electrolysis reactor is 4:1;

[0052] S4. Static sedimentation treatment is performed on the effluent of the process S3, and the iron-carbon filler in the water is separated;

[0053] S5, passing the effluent of the process...

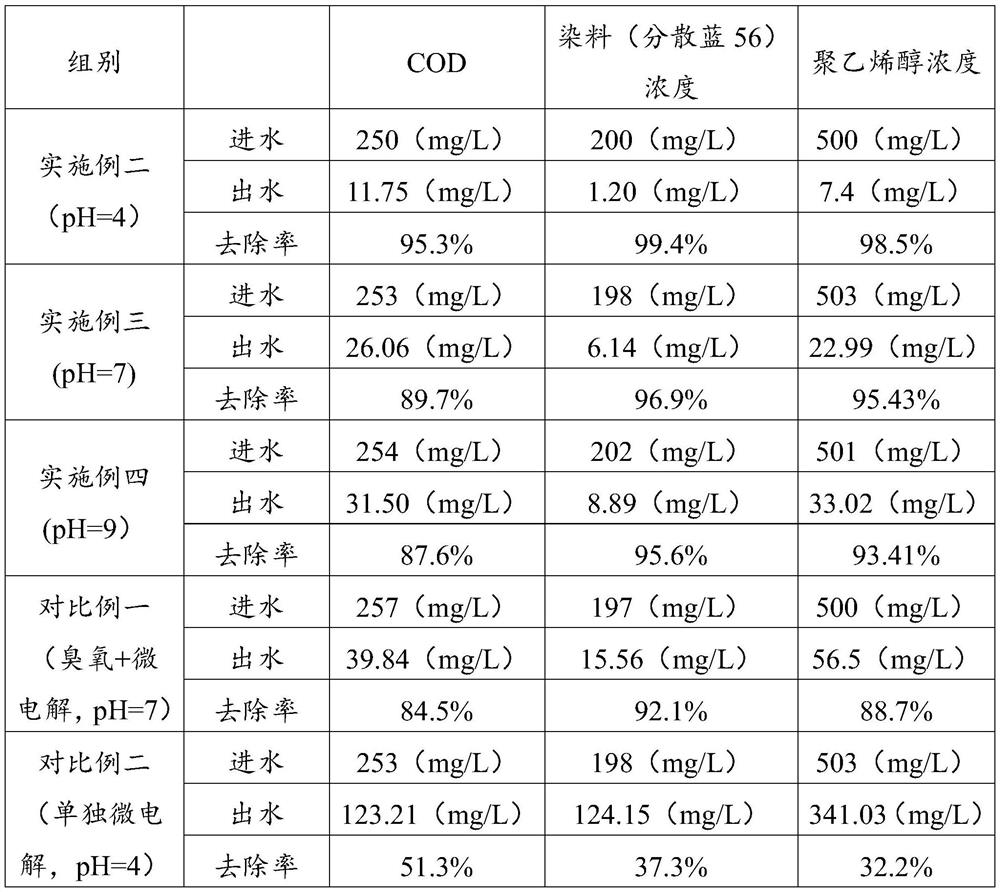

Embodiment 3

[0055] Embodiment three, refractory wastewater treatment process

[0056] The difference between the third embodiment and the second embodiment is that the step S1 adjusts the pH to 7, and the other parameters are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com