Petrochemical lightweight refractory castable

A castable and refractory technology, applied in the field of metallurgy, can solve the problems of increasing the risk of burns, high temperature of the container shell, and damage to the lining refractory material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The second aspect of the present invention provides the preparation method of the lightweight refractory castable provided by the first aspect of the present invention, those skilled in the art can choose a suitable method, through the formula of the lightweight refractory castable provided by the first aspect of the present invention A lightweight refractory castable is prepared. For example, the preparation method is usually physical mixing, which may specifically include: mixing the components according to the formula provided in the first aspect of the present invention, and the mixing time may be 170-200s, 170-180s, 180-190s, or 190-200s.

[0034] The third aspect of the present invention provides the use of the lightweight castable refractory material provided by the first aspect of the present invention as a lining refractory material for a reactor. As mentioned above, during the reaction process of some reactors (such as petroleum catalytic crackers), the equip...

Embodiment 1

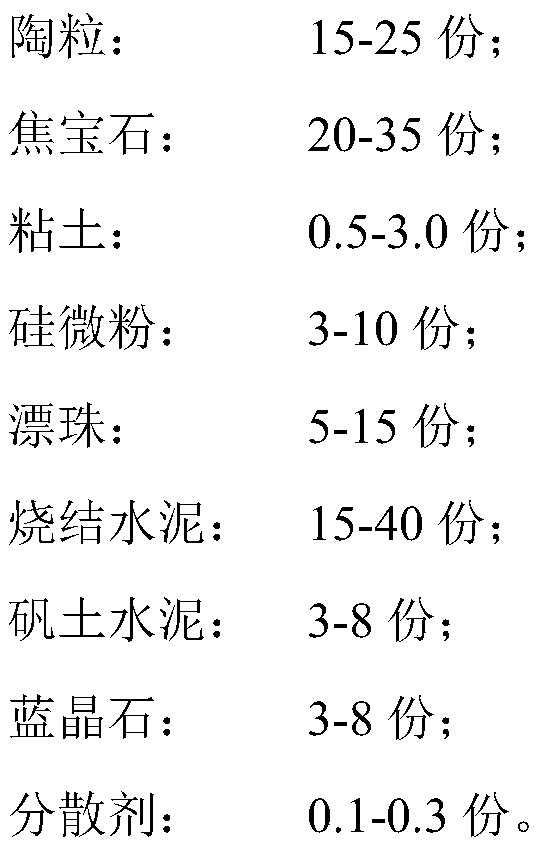

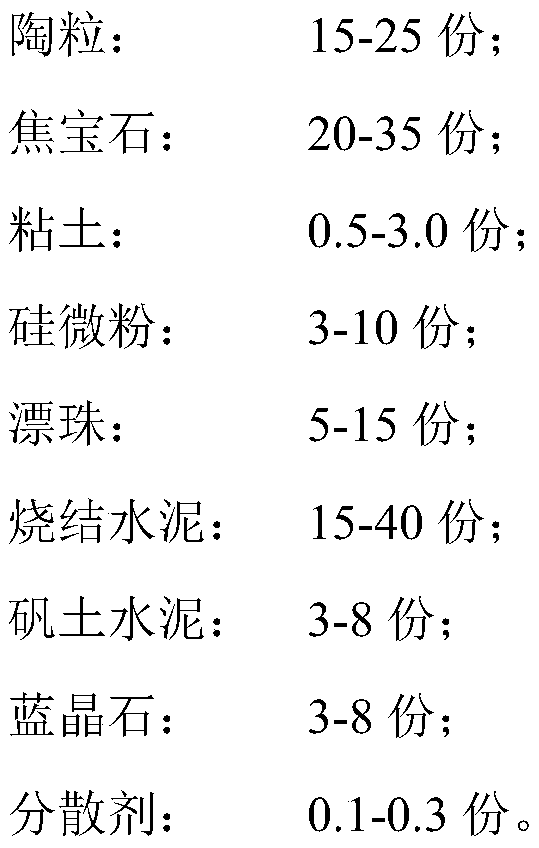

[0039] The raw material formula ratio of each sample in the embodiment is as shown in table 1:

[0040] Table 1

[0041] Raw material name sample 1 sample 2 sample 3 Ceramsite (3-5mm) 15 17 25 Focus gem (1-3mm) 17.5 13.5 17.5 Focus gem (0-1mm) 17.5 13.5 17.5 Suzhou Clay 1.8 0.8 2.8 Silica powder (920μ) 8 6 3 Floating beads (floating matter ≥ 90%) 5 11 9 Sintered cement (S-68) 12.5 14 7.5 Sintered cement (A-75) 12.5 14 7.5 Alumina Cement(925) 5 5 5 Kyanite (60 mesh) 5 5 5 M-100 0.1 0.1 0.1 P530 0.1 0.1 0.1

[0042] When preparing lightweight refractory castables for petrochemicals, set the formula on the main console according to the process flow, and weigh the small dispersant material. Start the metering equipment, accurately weigh each material to the intermediate weighing silo, and then enter the conveying system; the conveying system enters the mixer through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com