An explosive composition containing aluminum

A technology of composition and aluminum powder, applied in explosives and other directions, can solve problems such as the application of compounds that have not been seen before, and achieve the effect of good safety and low impact sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

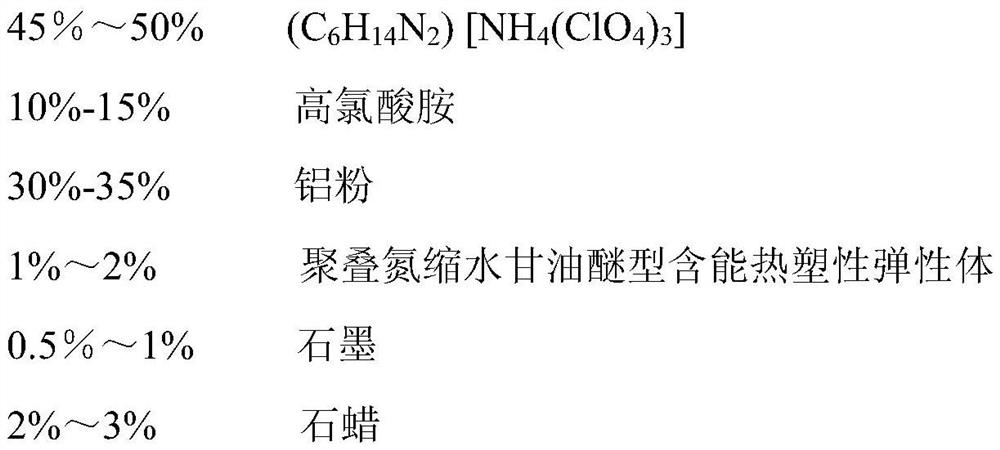

Method used

Image

Examples

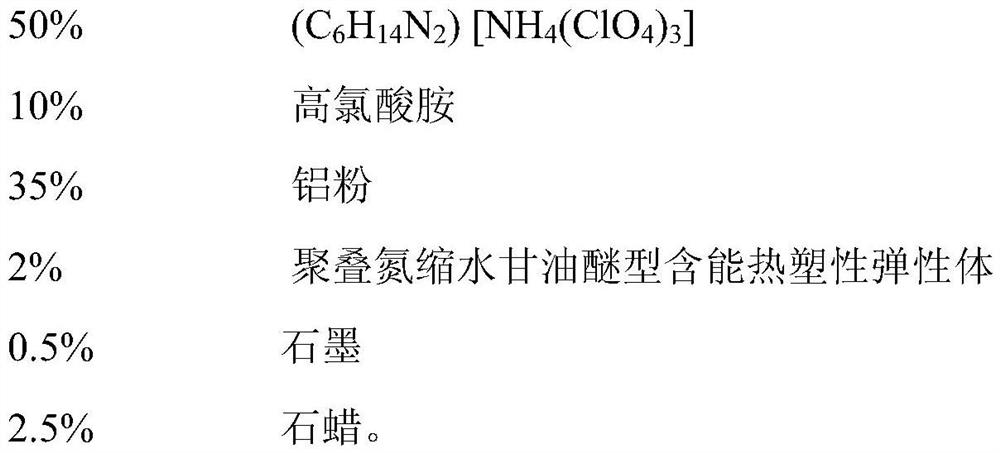

Embodiment 1

[0013] The present embodiment is implemented with reference to the following mass percentage composition: 50% (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ], 10% ammonium perchlorate, 35% aluminum powder, 2% polyazide glycidyl ether type energetic thermoplastic elastomer, 0.5% graphite, 2.5% paraffin.

[0014] The preparation method of this embodiment (taking 1000g as an example): the temperature of the granulation kettle is adjusted to 65°C±2°C, and 500g (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ] compound and 100g ammonium perchlorate were added to the granulation kettle, 100mL dichloroethane solvent was added to infiltrate, after mixing evenly, the petroleum ether solution of 25g paraffin was added to the granulation kettle, stirred for 10min, and then 20g polyazide was added Put the dichloroethane solution of glycidyl ether-type energetic thermoplastic elastomer into the above mixture, stir for 10 minutes, then add 350g of aluminum powder and 5g of graphite into the above mixture, and ...

Embodiment 2

[0016] The present embodiment is implemented with reference to the following mass percentage composition: 45% (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ], 15% ammonium perchlorate, 35% aluminum powder, 2% polyazide glycidyl ether type energetic thermoplastic elastomer, 0.5% graphite, 2.5% paraffin.

[0017] The preparation method of this embodiment (taking 1000g as an example): the temperature of the granulation kettle is adjusted to 65°C ± 2°C, and 450g (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ] compound and 150g of ammonium perchlorate were added to the granulation kettle, and 100mL dichloroethane solvent was added to infiltrate it. After mixing evenly, 25g of paraffin petroleum ether solution was added to the granulation kettle, stirred for 10min, and then 20g of polyazide was added Put the dichloroethane solution of glycidyl ether-type energetic thermoplastic elastomer into the above mixture, stir for 10 minutes, then add 350g of aluminum powder and 5g of graphite into the above mi...

Embodiment 3

[0019] The present embodiment is implemented with reference to the following mass percentage composition: 50% (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ], 15% ammonium perchlorate, 30% aluminum powder, 2% polyazide glycidyl ether type energetic thermoplastic elastomer, 0.5% graphite, 2.5% paraffin.

[0020] The preparation method of this embodiment (taking 1000g as an example): the temperature of the granulation kettle is adjusted to 65°C±2°C, and 500g (C 6 h 14 N 2 )[NH 4 (ClO 4 ) 3 ] compound and 150g of ammonium perchlorate were added to the granulation kettle, and 100mL dichloroethane solvent was added to infiltrate it. After mixing evenly, 25g of paraffin petroleum ether solution was added to the granulation kettle, stirred for 10min, and then 20g of polyazide was added Put the dichloroethane solution of glycidyl ether-type energetic thermoplastic elastomer into the above mixture, stir for 10 minutes, then add 300g of aluminum powder and 5g of graphite into the above mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com