Key technique of three-dimensional laser scanning in deformation monitoring

A three-dimensional laser and deformation monitoring technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of reduced work efficiency, reduced data processing speed, and increased data volume of three-dimensional laser scanners, and improved data processing speed. The effect of reducing the amount of data and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

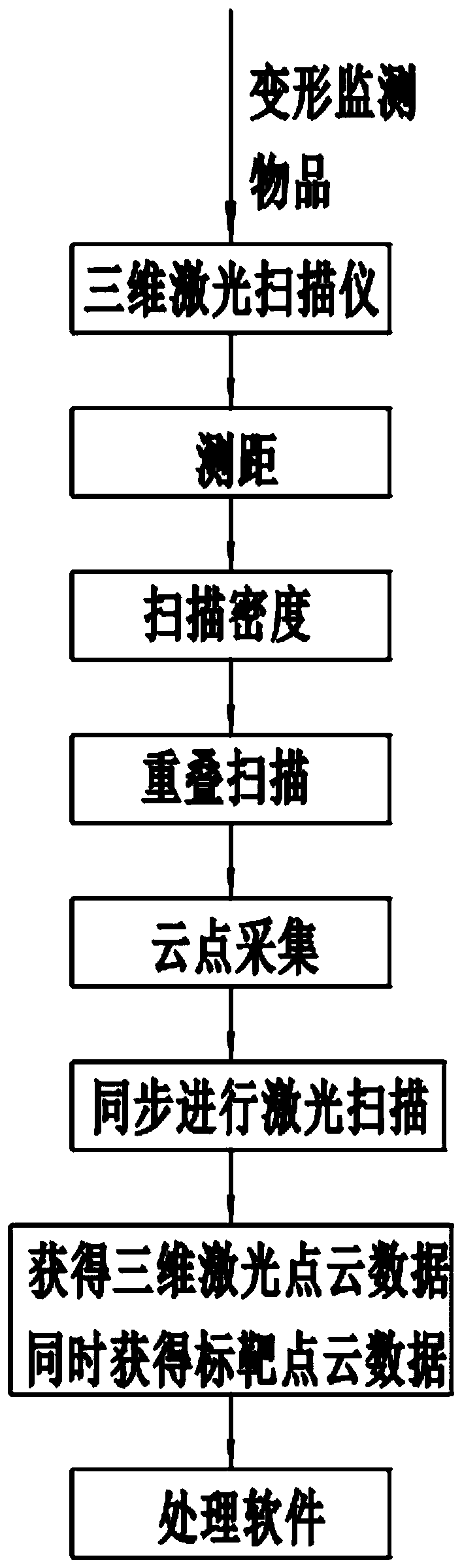

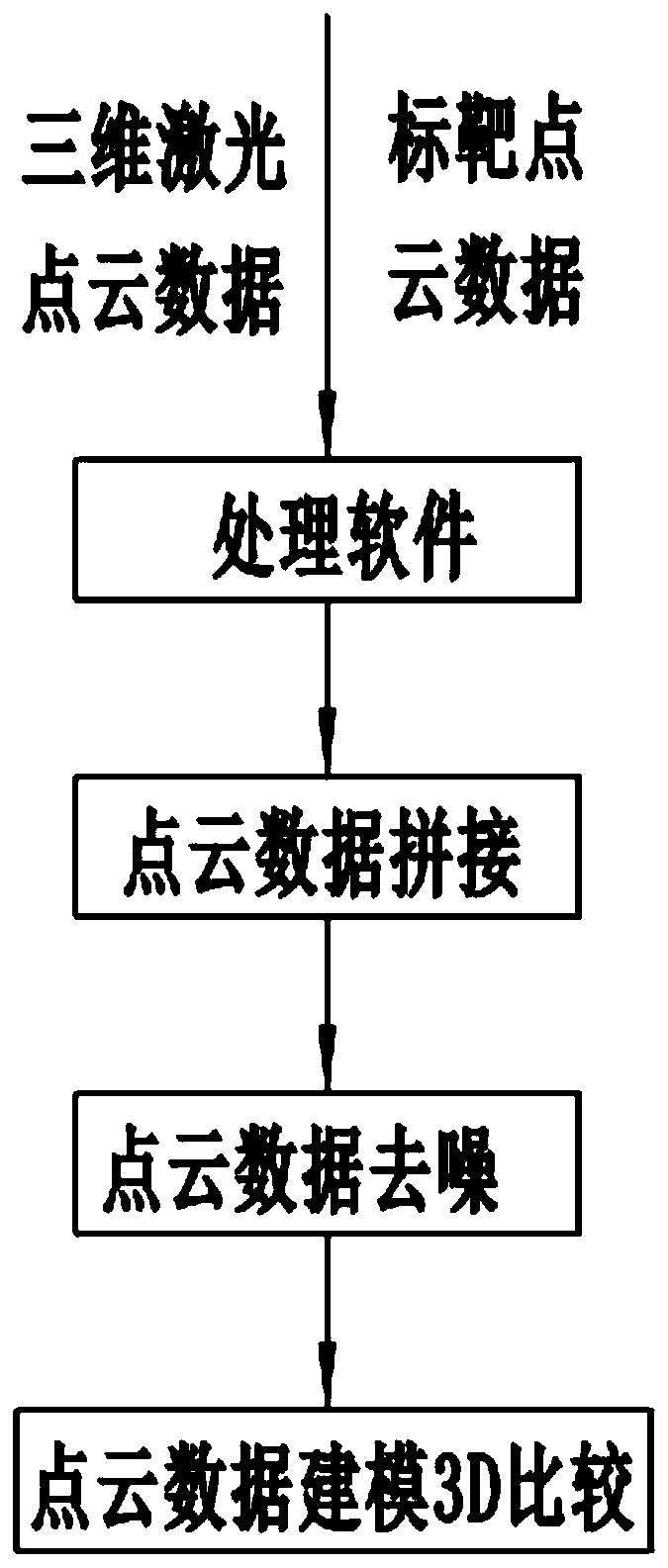

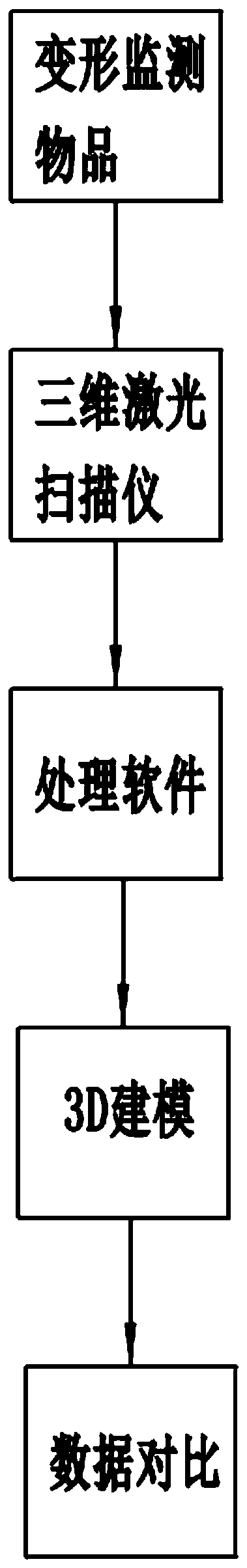

[0034] The key technology of 3D laser scanning in deformation monitoring, including the general steps of 3D laser scanner measurement: deformation detection items are scanned and measured by 3D laser scanner, the data measured and scanned by 3D laser scanner are sent to the processing software for processing, and the processing software Carry out 3D modeling of the scanned data, and compare the data through the 3D modeling models formed in different periods. The specific steps of the three-dimensional laser scanner measurement: the first choice for deformation detection items is to use the three-dimensional laser scanner for distance measurement, and then carry out the deformation monitoring items Carry out preliminary scanning, in which it is necessary to increase the scanning density during scanning, and then carry out overlapping scanning of the deformation monitoring items, and then collect cloud points of the deformation monitoring items, and use a 3D laser scanner to simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com