Two-way mirror observation system based on machine vision

A technology of machine vision and observation system, which is applied in the direction of instruments, measuring devices, optical devices, etc., and can solve problems such as strong light damage to human eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

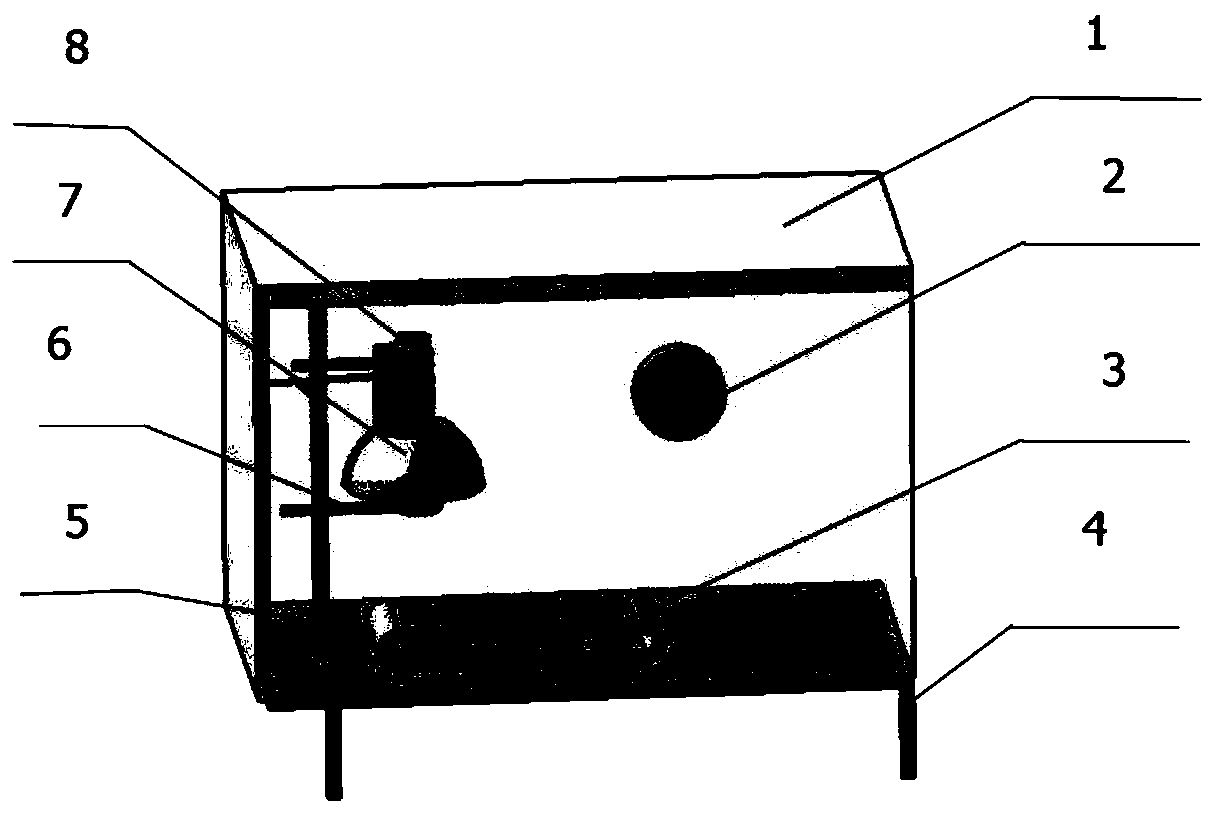

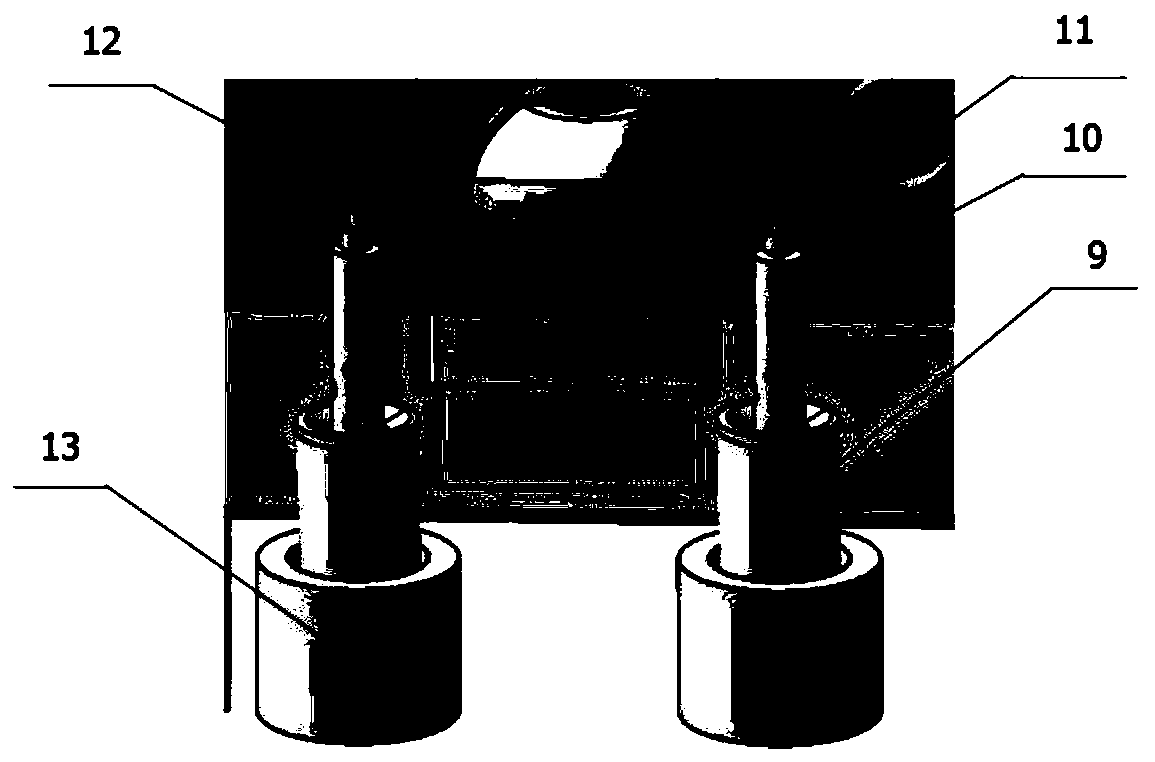

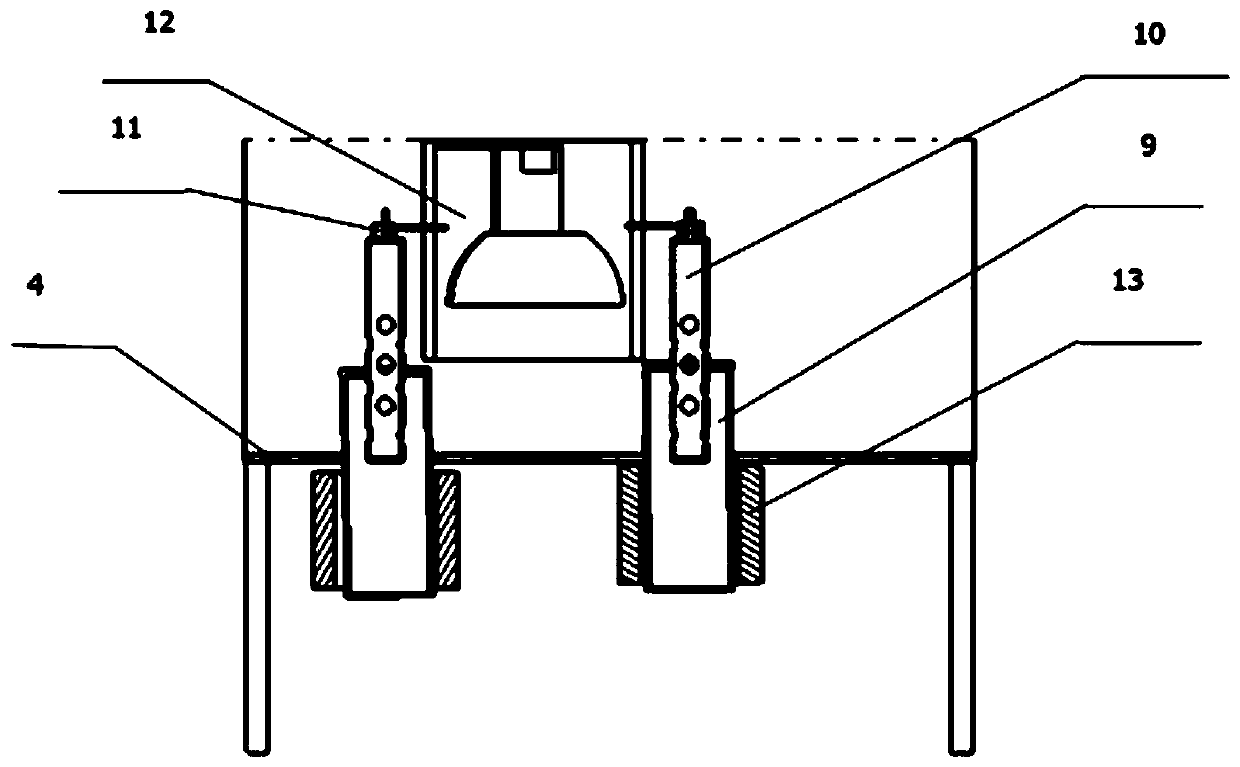

[0017] Such as figure 1 Shown, a kind of two-way mirror observation system based on machine vision, comprises, is located at the test bench 4 in the two-way mirror observation housing 1; On the test bench 4, is provided with conveyer belt 3, utilizes this conveyer belt 3 to be able to transfer article, simultaneously in The test bench 1 on the conveyor belt 3 is provided with a light source 6, a reflector adjustment device 7 and an industrial camera 8 in turn through a camera frame 5; Simultaneously, the two-way mirror observation shell 1 of described reflector adjusting device 7 reflected light is provided with photosensitive sensor 2; For better observation, be provided with transparent light-transmitting layer on the hollow observation window of two-way mirror observation shell 1; An object-viewing two-way mirror 12 is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com