Beauty yogurt and preparation method thereof

A technology of yogurt and sialic acid, applied in the field of fermented milk, can solve the problem of not being able to meet the needs of consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiment of the invention provides a cosmetic yoghurt.

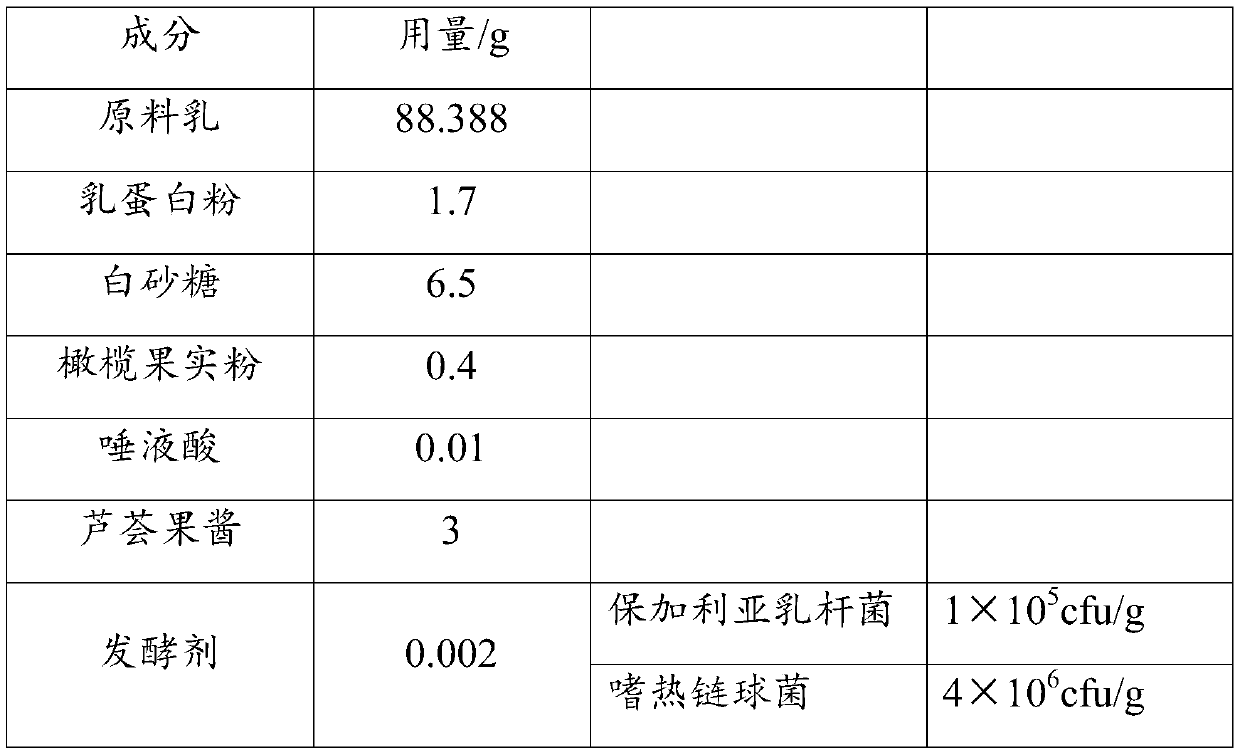

[0042] The raw material formula of described cosmetic yoghurt is as follows:

[0043]

[0044] Its production process is carried out according to the following steps:

[0045] (1) Preheat raw milk to 40°C, add white sugar, milk protein powder, sialic acid, olive fruit powder, keep warm and stir for 15 minutes;

[0046] (2) Homogenize the material obtained in step (1) at 60°C and 25MPa, sterilize at 95°C for 15s after homogenization, and cool to 38°C to obtain the fermentation base;

[0047] (3) drop starter (Streptococcus thermophilus and Lactobacillus bulgaricus) into the fermentation base material, and insulate and ferment at 38°C to an acidity of 75°T;

[0048] (4) Turn over the material obtained in step (3) and cool to 16° C. to terminate fermentation, put in aloe jam, stir evenly to obtain the final product.

Embodiment 2

[0050] The embodiment of the invention provides a cosmetic yoghurt.

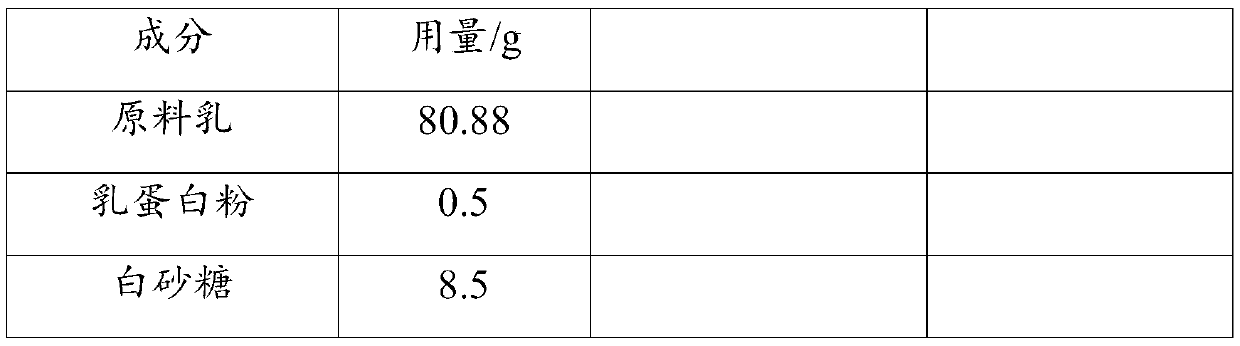

[0051] The raw material formula of described cosmetic yoghurt is as follows:

[0052]

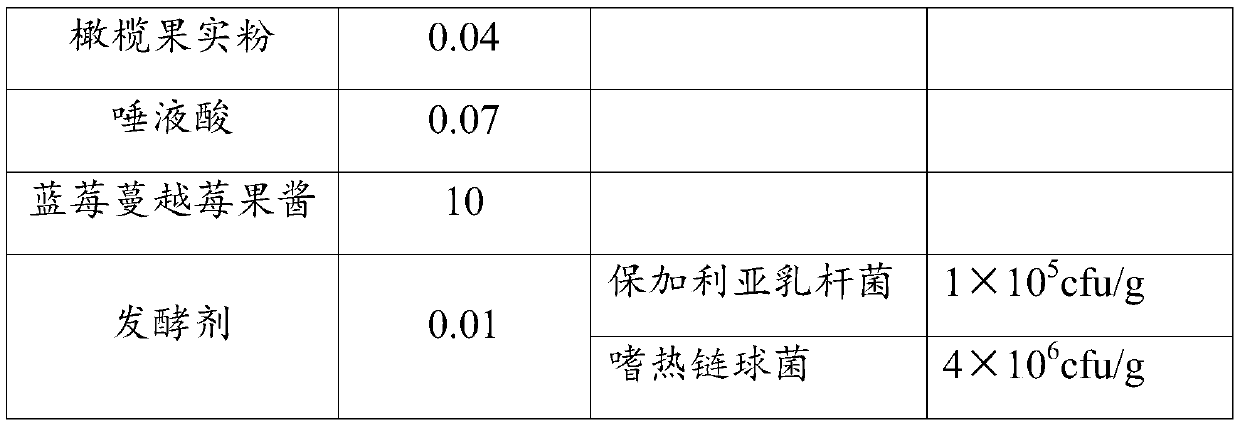

[0053]

[0054] Its production process is carried out according to the following steps:

[0055] (1) Preheat raw milk to 40°C, add white sugar, milk protein powder, sialic acid, olive fruit powder, keep warm and stir for 15 minutes;

[0056] (2) Homogenize the material obtained in step (1) at 65°C and 18MPa, sterilize at 95°C for 15s after homogenization, and cool to 42°C to obtain the fermentation base;

[0057] (3) Drop starter (Streptococcus thermophilus and Lactobacillus bulgaricus) into the fermentation base material, and insulate and ferment at 42°C to acidity 70°T;

[0058] (4) Turn over the material obtained in step (3) and cool it down to 22° C. to terminate fermentation, put in blueberry cranberry jam, and stir evenly to obtain the final product.

Embodiment 3

[0060] The embodiment of the invention provides a cosmetic yoghurt.

[0061] The raw material formula of described cosmetic yoghurt is as follows:

[0062]

[0063]

[0064] Its production process is carried out according to the following steps:

[0065] (1) Preheat raw milk to 40°C, add white sugar, milk protein powder, sialic acid, olive fruit powder, keep warm and stir for 30 minutes;

[0066] (2) Homogenize the material obtained in step (1) at 60°C and 20MPa, sterilize at 95°C for 15s after homogenization, and cool to 35°C to obtain the fermentation base material;

[0067] (3) Put starter (Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cream) into the fermentation base material, and heat-preserve and ferment at 35° C. until the acidity is 75° T;

[0068](4) Turn over the material obtained in step (3) and cool to 16° C. to terminate fermentation, put into sea buckthorn roselle jam, stir evenly to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com