Special injector for telescopic push rod type chain hemostatic device

A syringe and push rod technology, applied in the field of special syringes for telescopic push rod type chain type hemostatic devices, can solve the problems of inconvenient operation, incomplete hemostasis, poor hemostasis effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

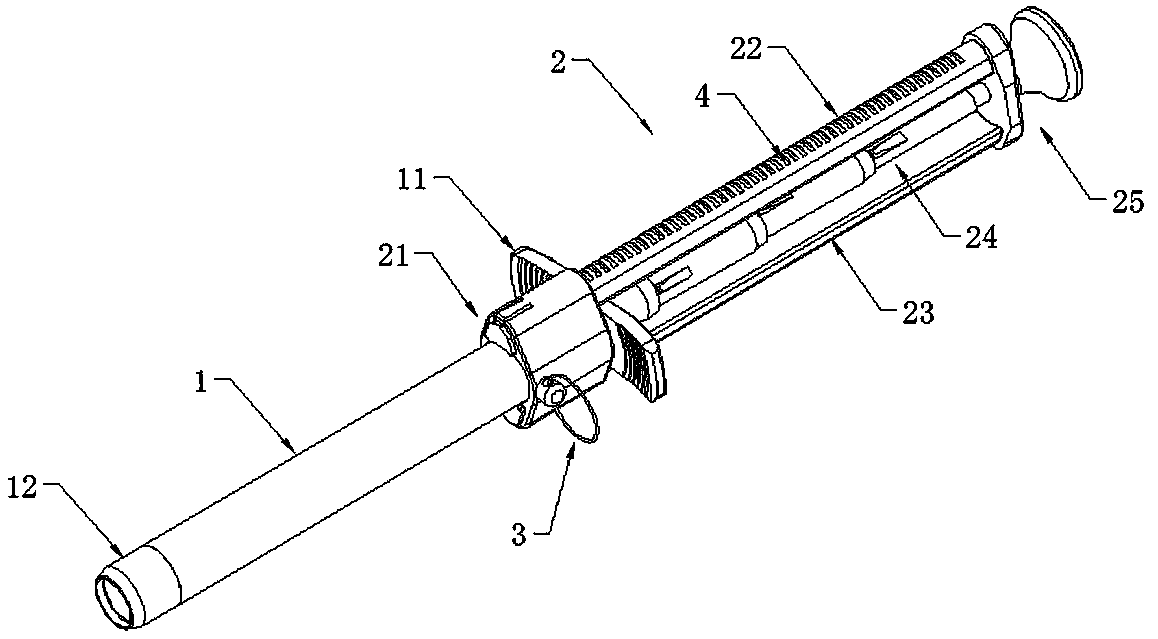

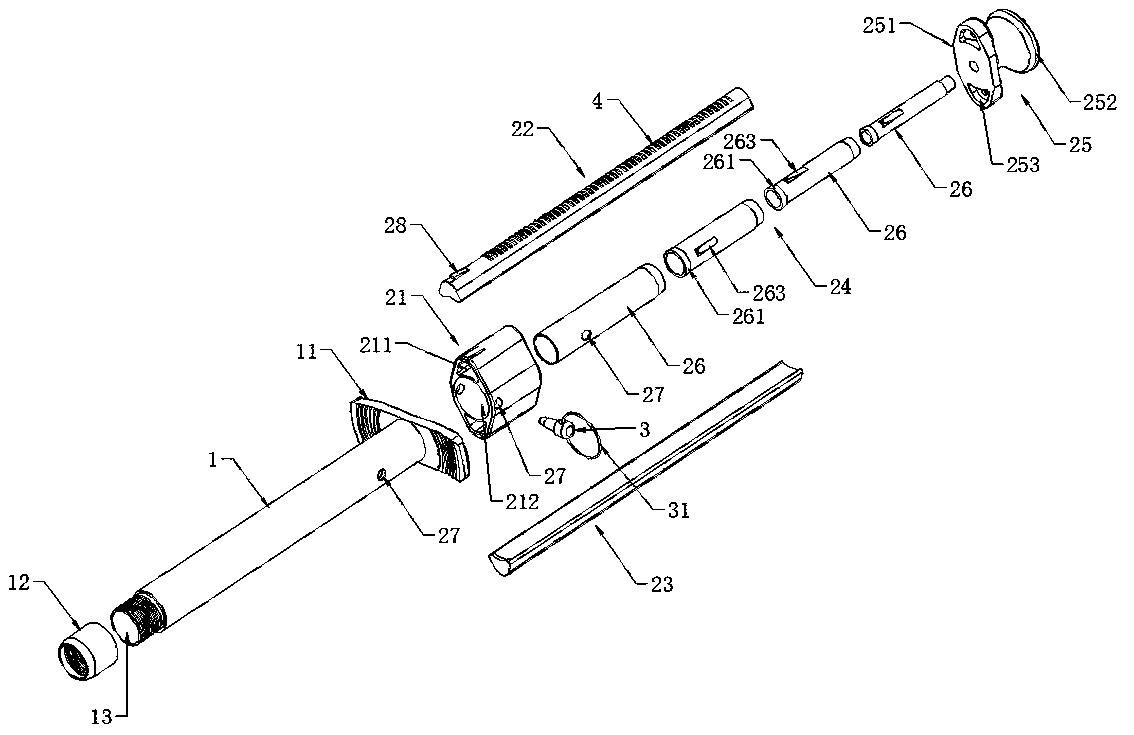

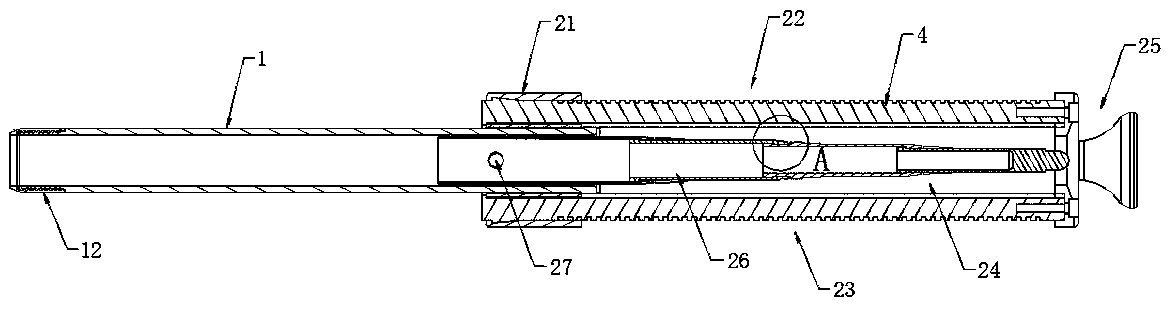

[0029] see Figure 1 to Figure 5 , a special syringe for telescopic push rod type chain hemostatic device, including a syringe 1 for storing the chain hemostatic device and a propulsion mechanism 2 for pushing the syringe 1 to move; the chain hemostatic device is made of an expandable A hemostatic chain formed by series connection of hemostatic materials, the adjacent hemostatic materials on the hemostatic chain can be extruded and shrunk and stored in the injection tube 1. When in use, the hemostatic chain is pushed into the wound for hemostasis; the tail of the injection tube 1 is fixed with a The handle 11 of the injection tube 1 is vertical and extends outward. The handle 11 is convenient for the operator to pull the injection tube 1; Cover piece 22 and lower cover piece 23, the telescopic push rod 24 that is arranged in the accommodatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com