Method and device for laser cleaning paint

A laser cleaning and painting technology, applied in the field of laser cleaning, can solve problems such as different scanning times, different paint thicknesses, and damage to cleaning objects, and achieve the effects of high automation, guaranteed efficiency, and avoiding workpiece damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

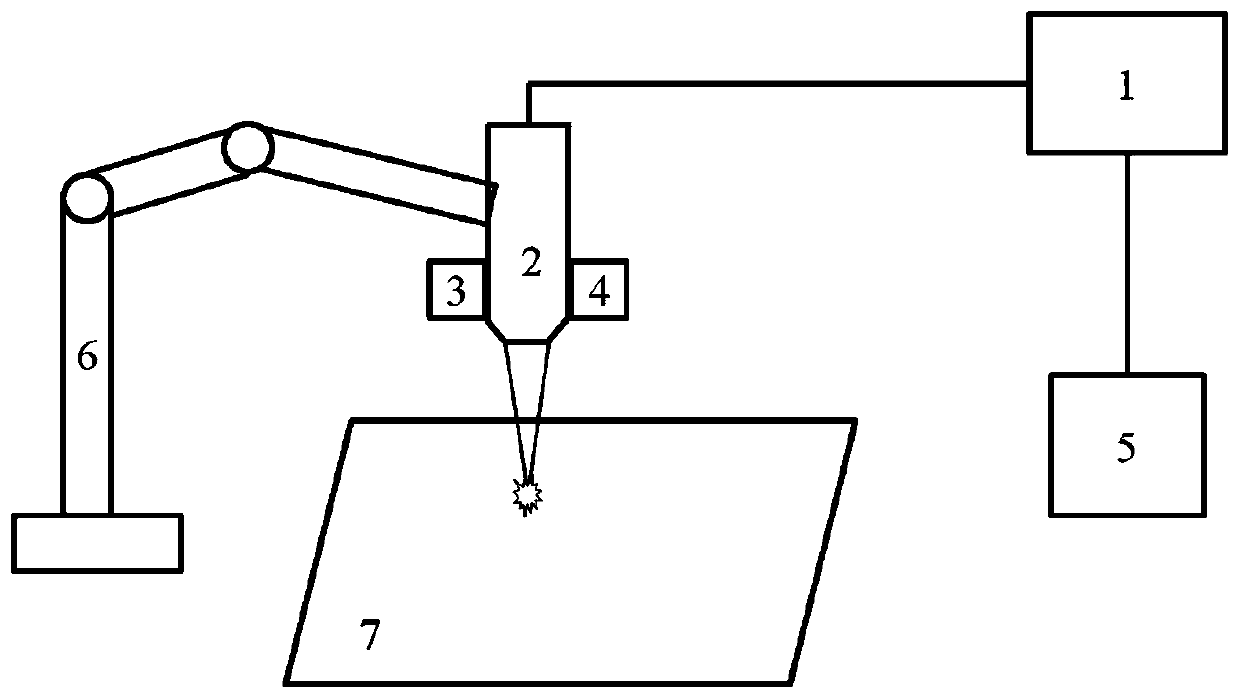

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

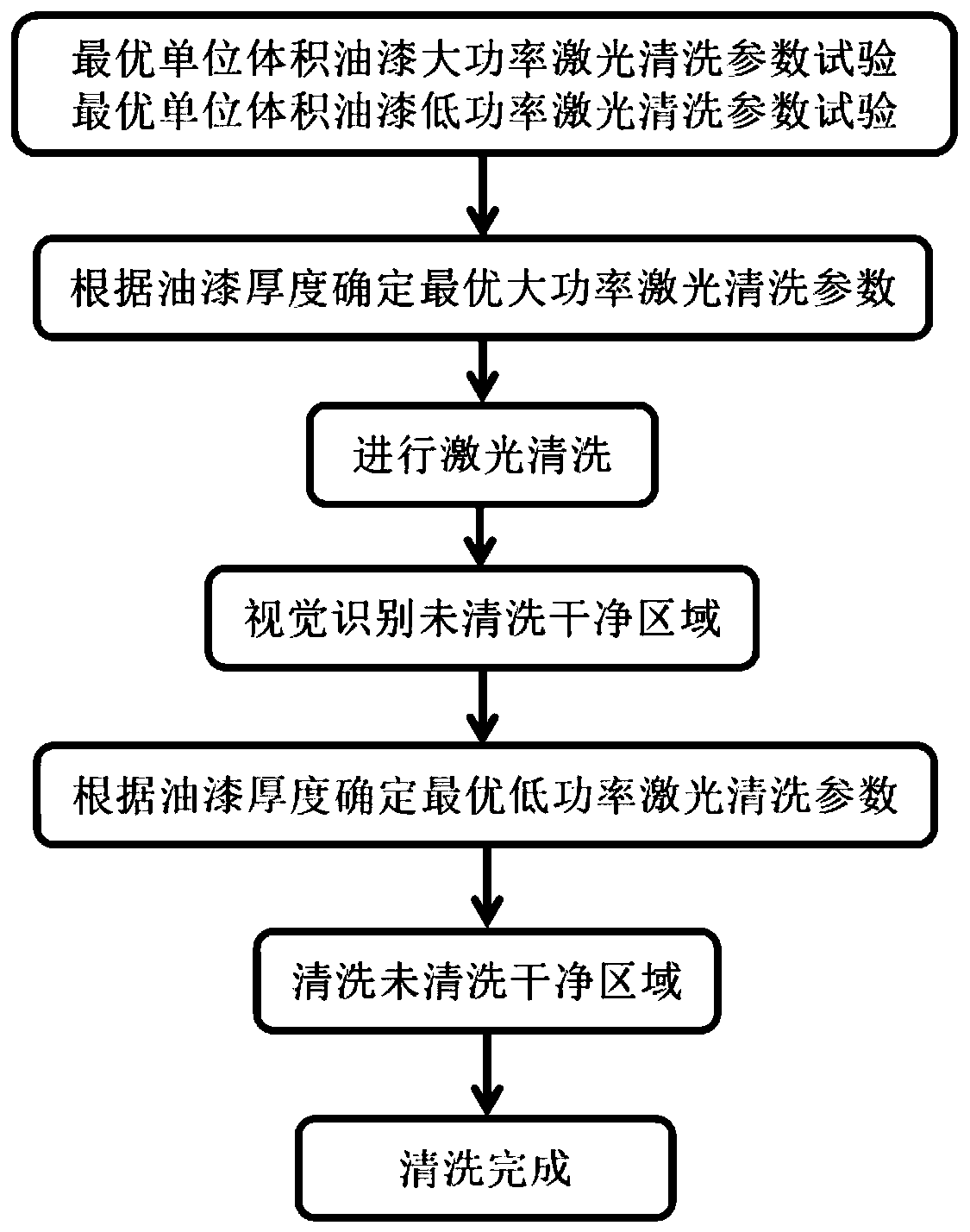

[0030] Such as figure 1 and figure 2 Shown, the method for the laser cleaning paint of the present embodiment comprises the following steps:

[0031] S01, establish the corresponding relationship between the average value of paint thickness on the surface of the workpiece 7 and the laser cleaning parameters;

[0032] S02. Measure the average paint thickness on the surface of the workpiece 7 to be cleaned, and select the corresponding laser cleaning parameters according to the corresponding relationship between the average paint thickness and the laser cleaning parameters in step S01;

[0033] S03. Perform laser cleaning on the paint on the surface of the workpiece 7 according to the laser cleaning parameters selected in step S02;

[0034] S04. After the cleaning is completed, check whether the cleaning surface is cleaned; if it is not clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com