A method for overall manufacturing of a large-sized, thin-walled annular oxygen-reinforced frame

A manufacturing method and frame strengthening technology, applied in the field of mechanical processing, to achieve good internal quality, reduce repeated clamping and positioning errors, and improve material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

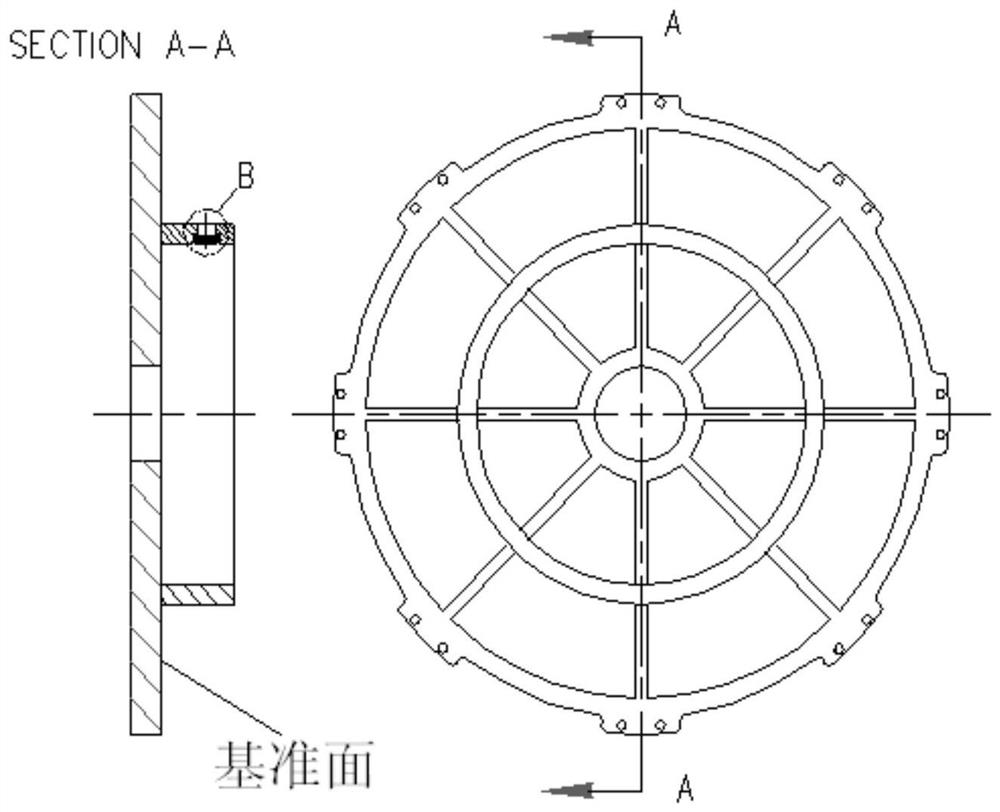

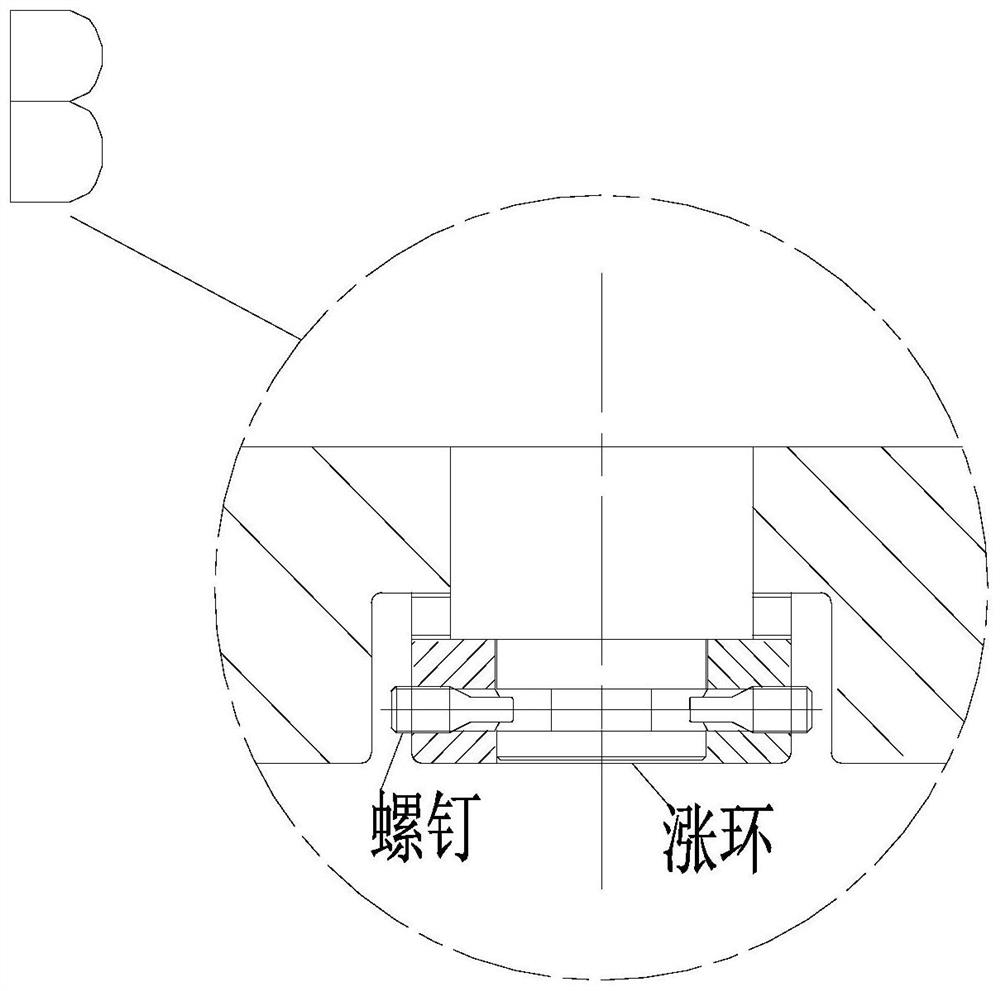

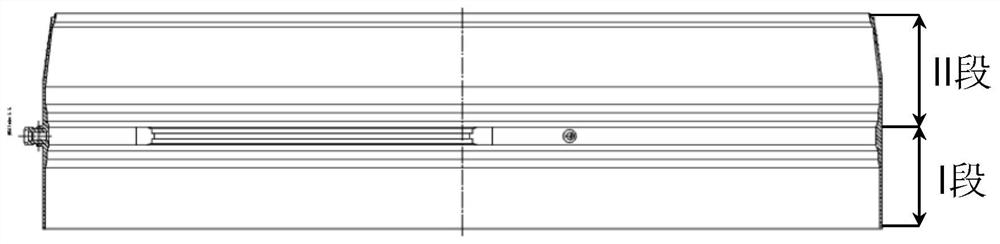

[0050] design as attached figure 1 As shown in the circular substrate, the substrate design thickness is >50mm to prevent deformation, and the dimensional tolerance meets the requirements of GB / T6414. Attached Picture 1-1 When the middle screw drives the expansion ring back or pushes out, ensure that the end faces of the screw and the expansion ring are lower than the end face of the positioning plate. Such as figure 2 The three-dimensional model diagram of the oxygen-reinforced frame parts is shown, and the three-dimensional model of the oxygen-reinforced frame is segmented along the horizontal direction above the rib plate of the oxygen-reinforced frame. Upper wall thickness transition region to part top face. For the inner and outer arcs of the model section I, place a margin of 1.5mm along the radial direction of the circle, and add a slant solid support at 68° to the deposition direction at the position of the lugs and ribs, and place 0.2mm along the radial direction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com