Method for determining the parallelism of ball linear guide assembly based on the dynamic characteristics of CNC machine tool feed system

A feed system, CNC machine tool technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem of different modal frequency distribution of the system, affecting the processing quality of parts and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described in detail below in conjunction with the embodiments and drawings, and the embodiments are to explain the present invention rather than limit it.

[0075] A method for determining the assembly parallelism of a ball linear guide based on the dynamic characteristics of a feed system of a CNC machine tool, comprising the following steps:

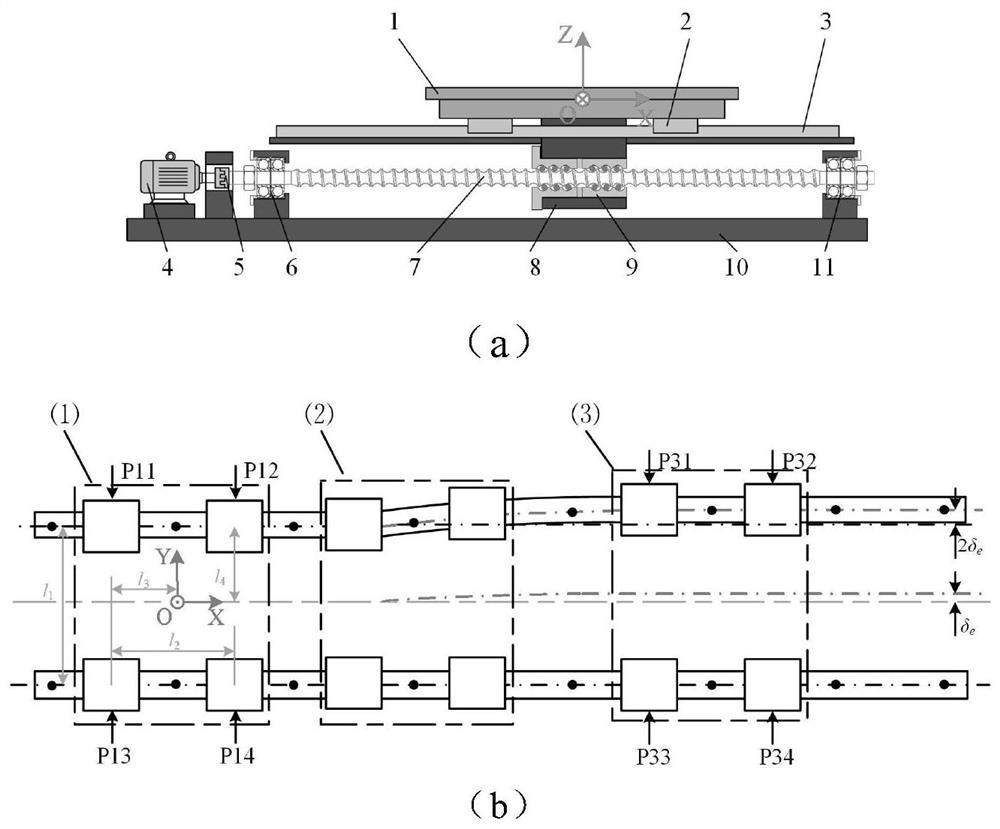

[0076] Step 1. For the feed system of the ball linear guide rail of the CNC machine tool, use the CAD software to obtain the center of mass position of the worktable through the established CAD model, and give a simplified diagram of the structure of the feed system including the coordinate system of the center of mass position of the workbench and the two guide rails Structural size relationship diagram of the span between and the distance between the two sliders;

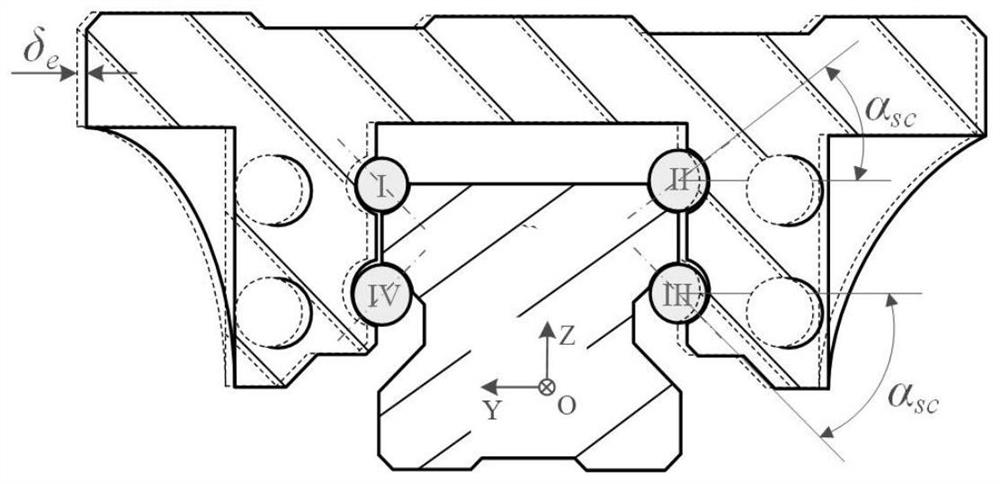

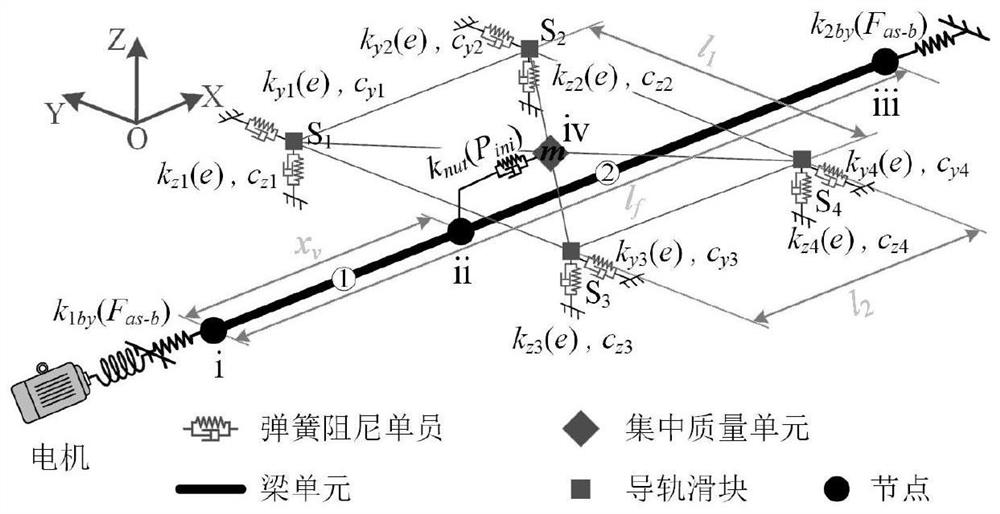

[0077] The schematic diagram of the feed system structure is as follows: figure 1 As shown in the middle picture (a), the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com