Method for packaging finished butadiene styrene rubber product pieces through packaging bags

A technology of styrene-butadiene rubber and packaging bags, which is applied in the directions of packaging, packaging protection, transportation and packaging, can solve problems such as incompatibility, and achieve the effects of being easy to use for a long time, improving stability, and facilitating stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

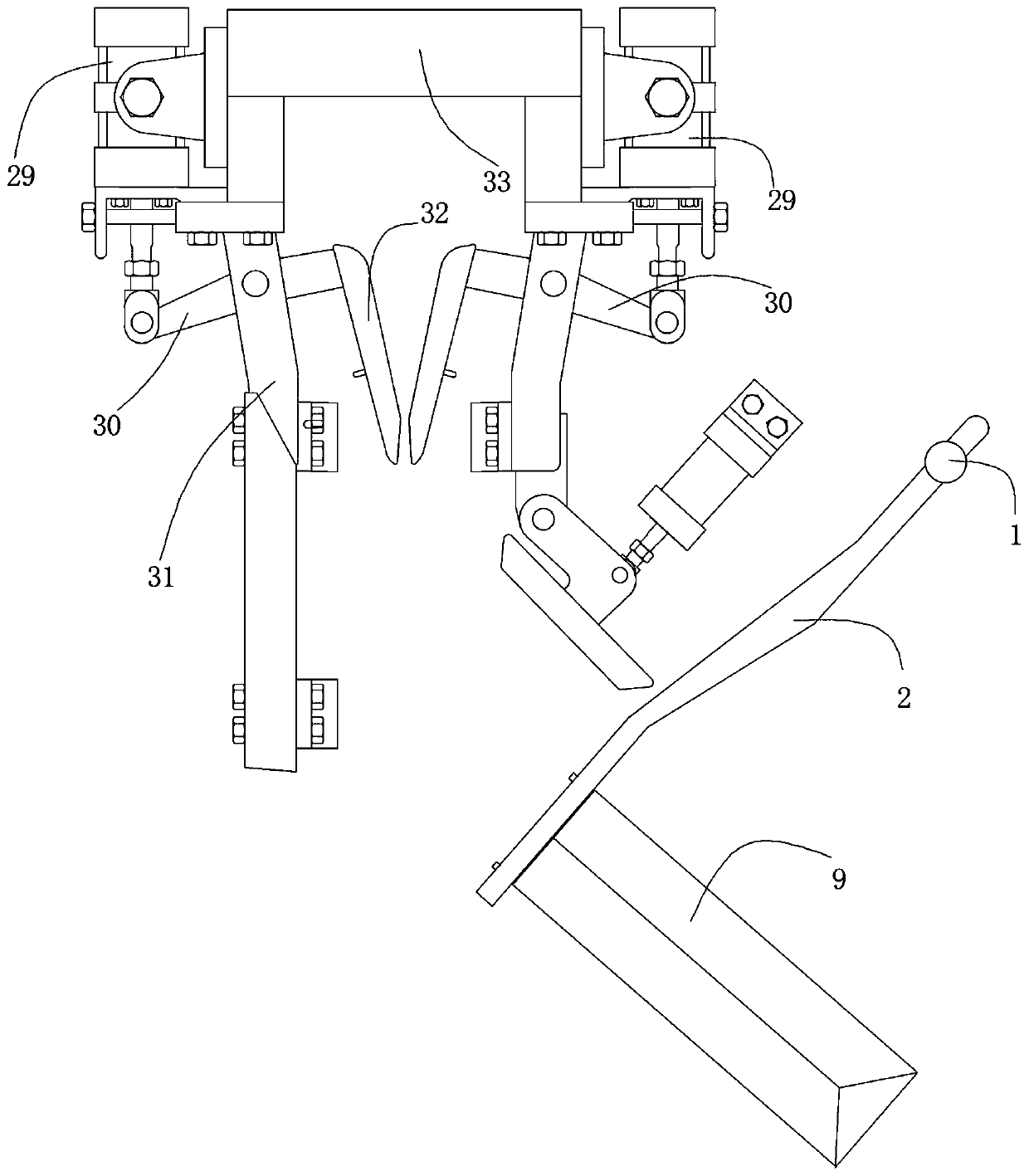

[0029] This styrene-butadiene rubber finished block packaging bag packaging method is used to pack the outer packaging bag 9 for the finished block 34, so that the packaging bag 9 is stretched from the sheet, so that the finished block 34 can smoothly enter the packaging bag.

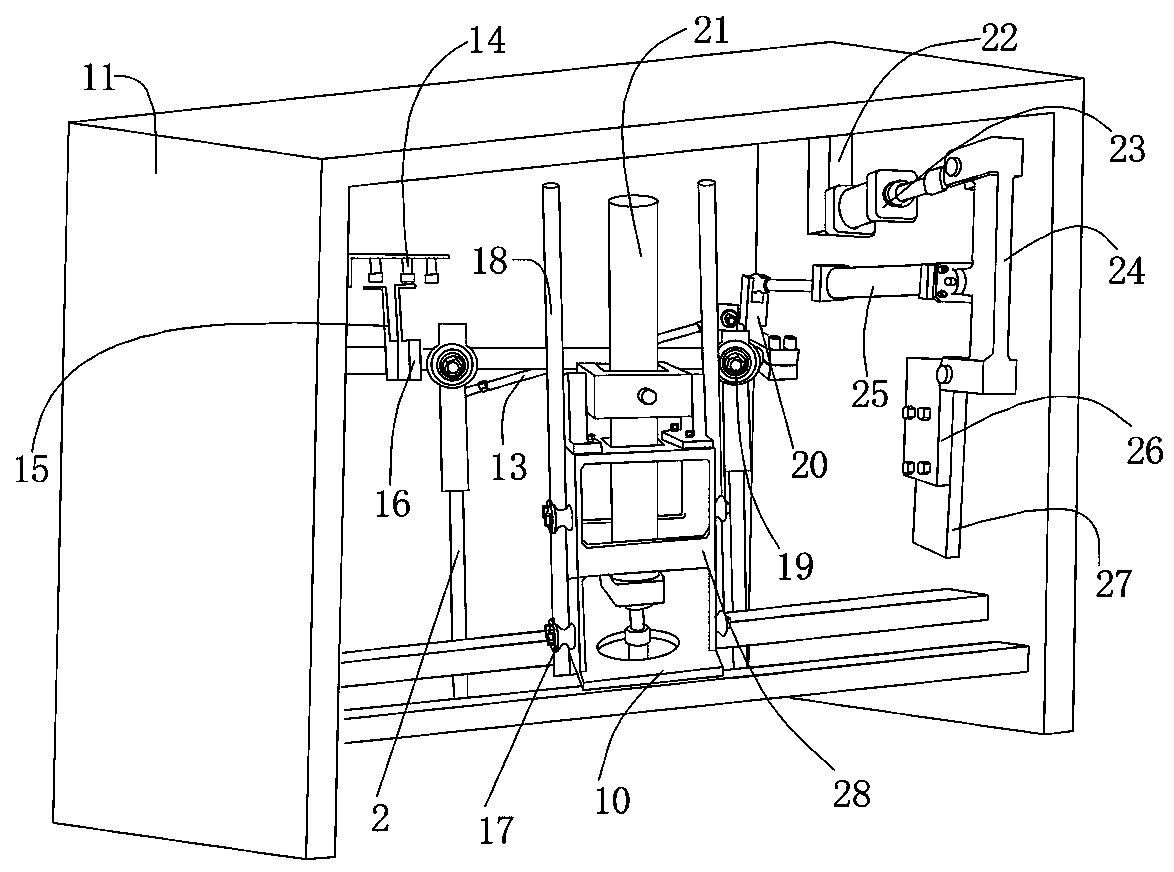

[0030] In order to realize automatic operation, this method needs to correspond to two sets of machines, one is a packaging bag extraction machine, and the other is a packaging bag closing machine. Below in conjunction with the specific structure of these two sets of machines, the present invention will be further described.

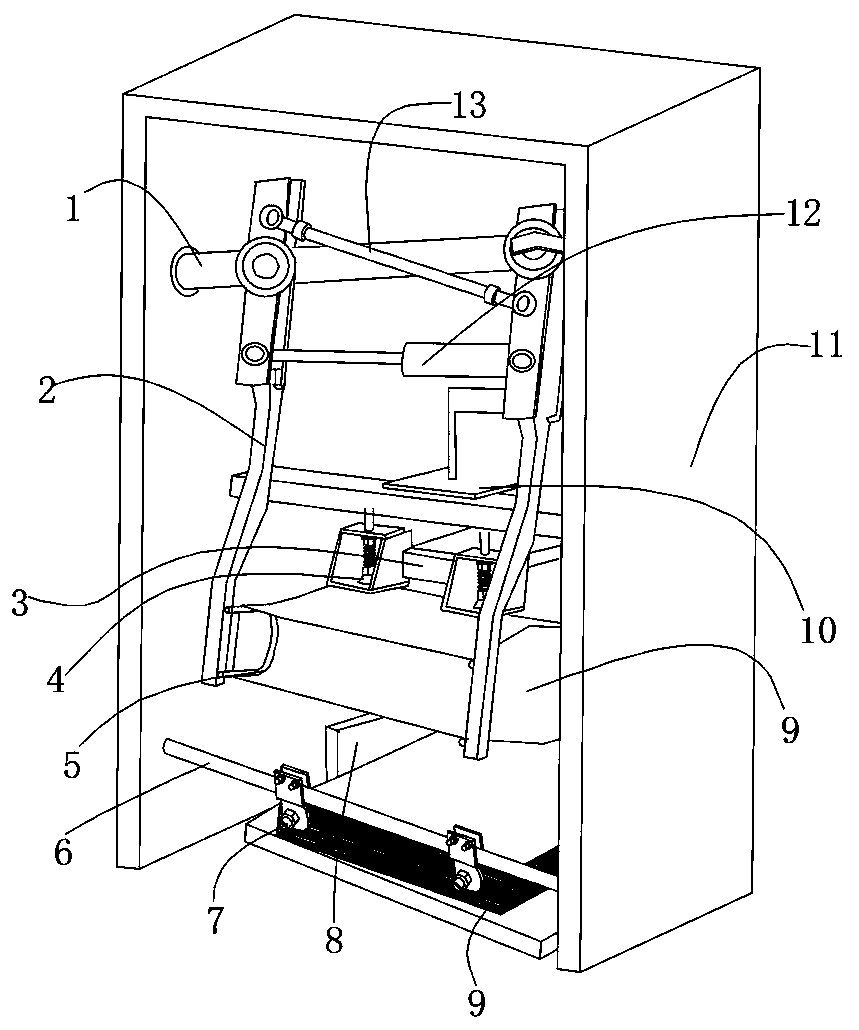

[0031] The structure of packaging bag extraction machine comprises frame 11, and frame 11 is X-shaped, and frame 11 provides support for some parts. A storage room is provided in the frame 11 , and the storage room is on the lower side in the frame 11 and is defined by the side panels 8 . The packaging bags 9 folded into sheets are stacked in the storage chamber, and the sheet-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com