A kind of colored non-slip pavement material and its preparation method and application

A pavement material and anti-slip technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as delamination and peeling, insufficient adhesion, and inability to realize rapid pavement of colored anti-slip thin layers on the road surface, achieving excellent The effect of anti-slip performance, simple construction, and extensive practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

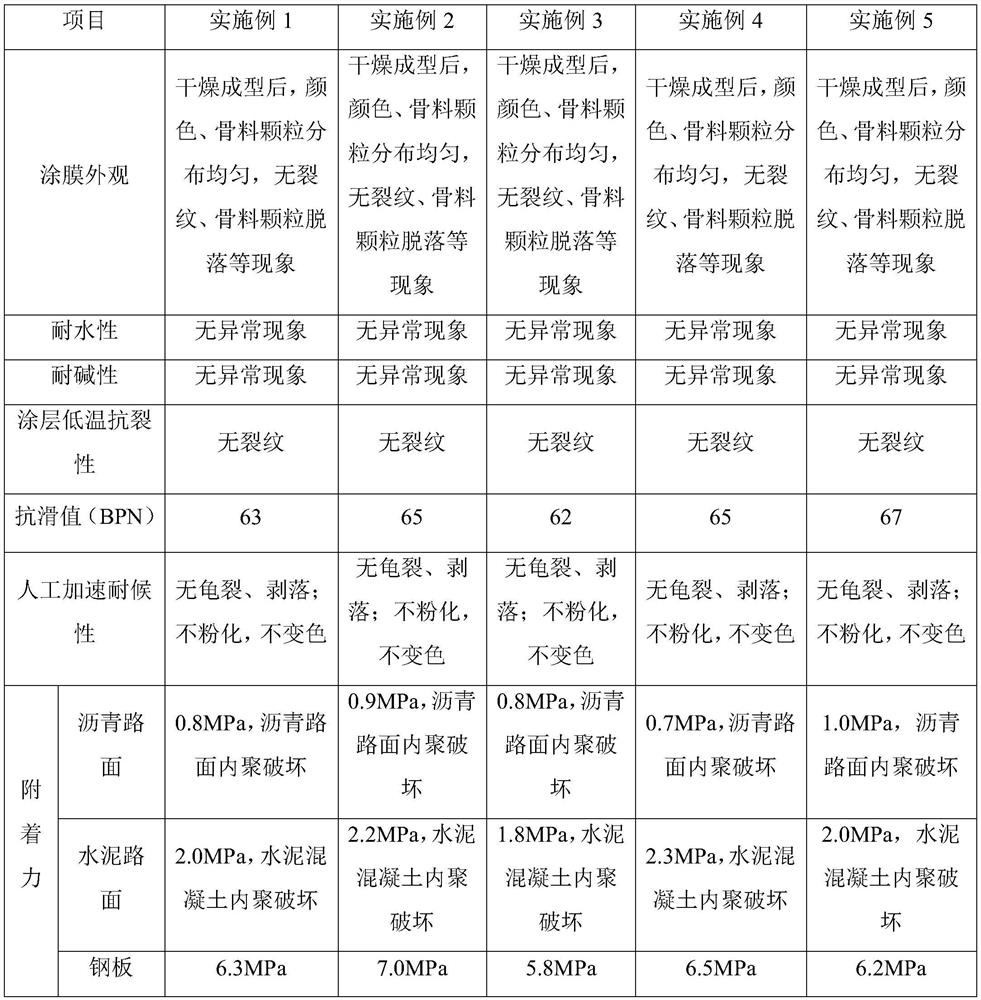

Examples

Embodiment 1

[0039] The preparation method of the colored non-slip paving material of the present embodiment may further comprise the steps:

[0040] 1) Add N,N-dimethylaniline to hydroxyethyl acrylate for dissolution;

[0041] 2) Mix liquid paraffin and 56# solid paraffin, heat and stir at 60°C until completely melted, then add the mixture prepared in step 1), stir well, and cool to room temperature;

[0042] 3) Mix and stir the 2-functionality urethane acrylate and 1,10-decanediol diacrylate evenly, then add the mixture prepared in step 2), and stir evenly;

[0043] 4) Add 600-mesh calcium carbonate and iron oxide red to the mixture prepared in step 3), stir well until the dispersion is uniform, and then grind with a sand mill to obtain a homogeneous and delicate glue;

[0044] 5) While stirring, add a mixture of 140-200 mesh silica and 1-2 mm red calcined ceramic aggregate into the glue, stir well, add tert-butyl peroxypivalate, and continue stirring for 1-2 mm. 2min, that is;

[004...

Embodiment 2

[0048] The preparation method of the colored non-slip paving material of the present embodiment may further comprise the steps:

[0049] 1) Add N,N-dimethyl-p-toluidine to hydroxypropyl acrylate for dissolution;

[0050] 2) Mix liquid paraffin and 54# solid paraffin, heat and stir at 60°C until completely melted, then add the mixture prepared in step 1), stir evenly, and cool to room temperature;

[0051]3) Mix and stir the 2-functionality urethane acrylate and 1,9-nonanediol diacrylate evenly, then add the mixture prepared in step 2), and stir evenly;

[0052] 4) Add 800-mesh calcium carbonate and chrome green to the mixture prepared in step 3), fully stir until the dispersion is uniform, and then grind with a sand mill to obtain a homogeneous and delicate glue;

[0053] 5) While stirring, add the mixture of 40-80 mesh silica and 1-3mm green calcined ceramic aggregate into the glue, stir well, add tert-butyl peroxyneodecanoate, and continue stirring for 1-3mm 2min, that is;...

Embodiment 3

[0057] The preparation method of the colored non-slip paving material of the present embodiment may further comprise the steps:

[0058] 1) adding N-methyl-N-hydroxyethyl p-toluidine to hydroxybutyl acrylate for dissolution;

[0059] 2) Mix liquid paraffin and 58# solid paraffin, heat and stir at 60°C until completely melted, then add the mixture prepared in step 1), stir evenly, and cool to room temperature;

[0060] 3) Mix and stir 3-functional polyurethane acrylate and 1,6-hexanediol diacrylate evenly, then add the mixture prepared in step 2), and stir evenly;

[0061] 4) Add 1000 meshes of calcium carbonate, iron oxide yellow, and iron oxide green to the mixture prepared in step 3), stir well until the mixture is evenly dispersed, and then grind with a sand mill to obtain a homogeneous and delicate glue;

[0062] 5) While stirring, add a mixture of 80-140 mesh silica and 1-2mm green calcined ceramic aggregate into the glue, stir well, add tert-butyl peroxy octanoate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com