A kind of reactor manufacturing process

A manufacturing process and reactor technology, applied in the field of reactor production and manufacturing technology, can solve the problems of different caliber metal substrate processing, low adaptability, poor equipment use effect, etc., to ensure the use effect, good adjustment effect, and smear good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

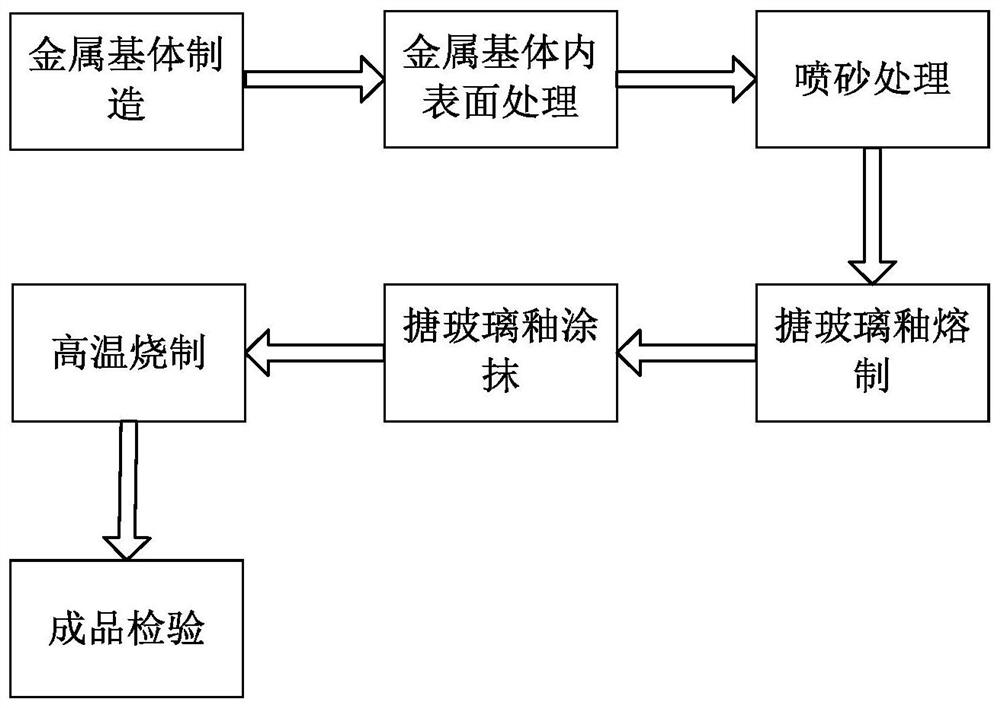

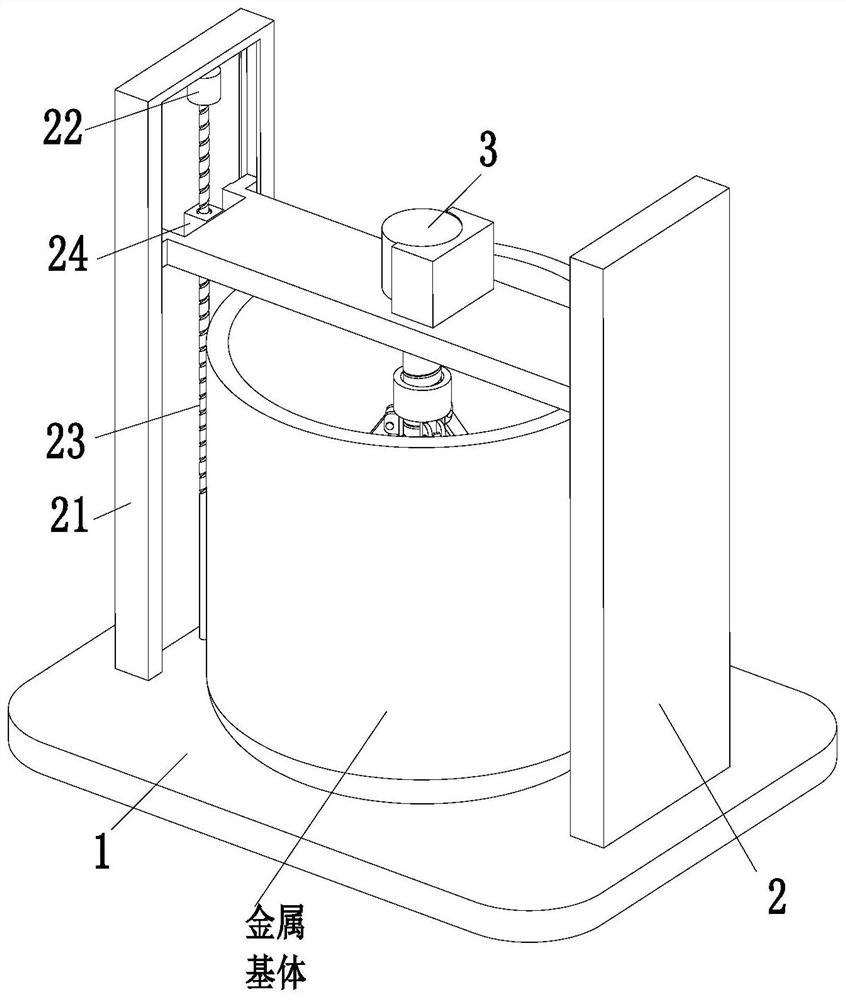

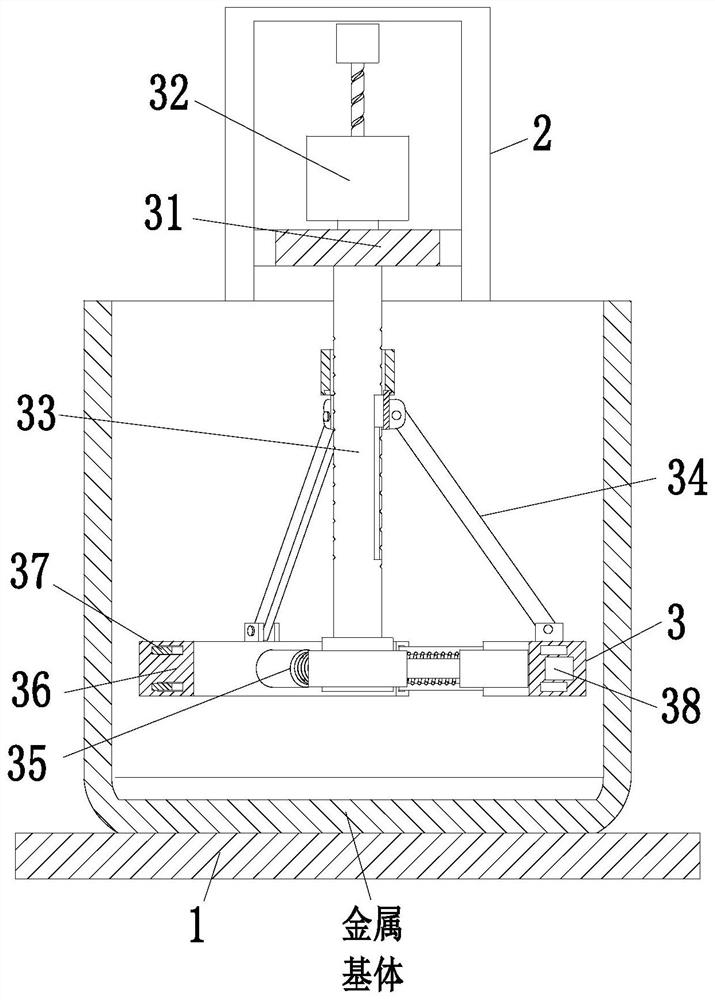

[0036] Such as Figure 1 to Figure 7 Shown, a kind of reactor manufacturing process comprises the following steps:

[0037] S1. Manufacture of metal matrix: press the steel plate into a metal matrix that meets the firing requirements, and the cross-section of the metal matrix has an "Ω"-shaped structure;

[0038] S2. Inner surface treatment of the metal matrix: remove impurities such as burrs, iron oxide scale and welding slag remaining on the inner surface of the metal matrix by pickling;

[0039] S3. Sandblasting treatment: the inner surface of the metal substrate is treated by high-speed sandblasting, so that uniform pits are formed on the inner surface of the metal substrate, the mechanical properties of the workpiece are improved, and the bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com