Automatic-control ash removal device for boiler in thermal power plant

A technology for cleaning devices and thermal power plants, applied to lighting and heating equipment, etc., can solve problems such as increased labor intensity of workers, insufficient combustion of combustibles, and impact on air quality, so as to facilitate fuel injection, increase cleanliness, and avoid flying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

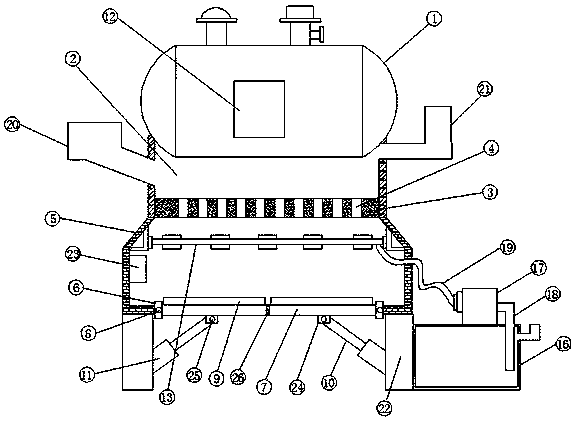

[0024] see Figure 1-2 According to an embodiment of the present invention, an automatic control and cleaning device for boiler dust in a thermal power plant includes a boiler body 1, a furnace 2 is provided at the bottom of the boiler body 1, and a combustion placement plate 3 is provided at the bottom of the furnace 2, The combustion placement plate 3 is provided with a plurality of through holes 4, the bottom side of the boiler body 1 is provided with a base 5, and the inside of the base 5 is provided with a cavity, between the cavity and the furnace 2 Connected by the through hole 4, the bottom of the base 5 is provided with a discharge port, both sides of the discharge port are fixed with a fixed plate 6, and one side of the fixed plate 6 is provided with a movable plate 7, so One side of the movable plate 7 is movably connected with the fixed plate 6 through a rotating shaft 8, one side of the movable plate 7 is fixedly provided with a pressure sensor 9, and the other si...

Embodiment 2

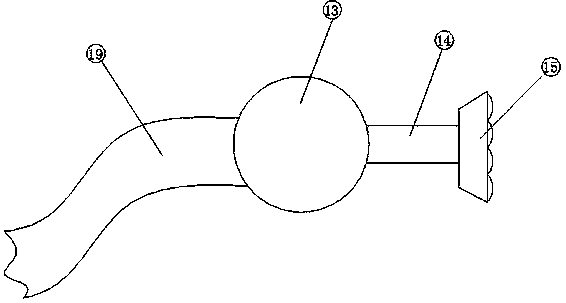

[0026] see Figure 1-2 , for the cavity, the interior of the cavity is provided with a spraying device, the spraying device includes a water main pipe 13, and one side of the water main pipe 13 is provided with several branch pipes 14, and the branch pipes 14 are far away from the One side of the main water pipe 13 is provided with a shower nozzle 15, and one end of the water main pipe 13 is connected with a water supply device, and the spray device can settle the dust produced by the combustion to avoid the flying of the dust.

Embodiment 3

[0028] For the water supply device, the water supply device includes a water tank 16, the top of the water tank 16 is provided with a water pump 17, one end of the water pump 17 is provided with an outlet pipe 18, and the other end of the water pump 17 is provided with a hose 19, The end of the flexible hose 19 away from the water pump 17 passes through the base 5 and communicates with the water main pipe 13 , the water supply device can provide water to the spraying device, and deliver the water from the water tank 16 to the spray head 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com