A diesel engine radiator

An engine and radiator technology, which is applied in the cooling of engine components, machines/engines, and engines, can solve the problems that the radiator cannot meet the cooling requirements, affects the service life of the engine, and has a slow cooling speed, and achieves a simple and practical structure. High performance, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

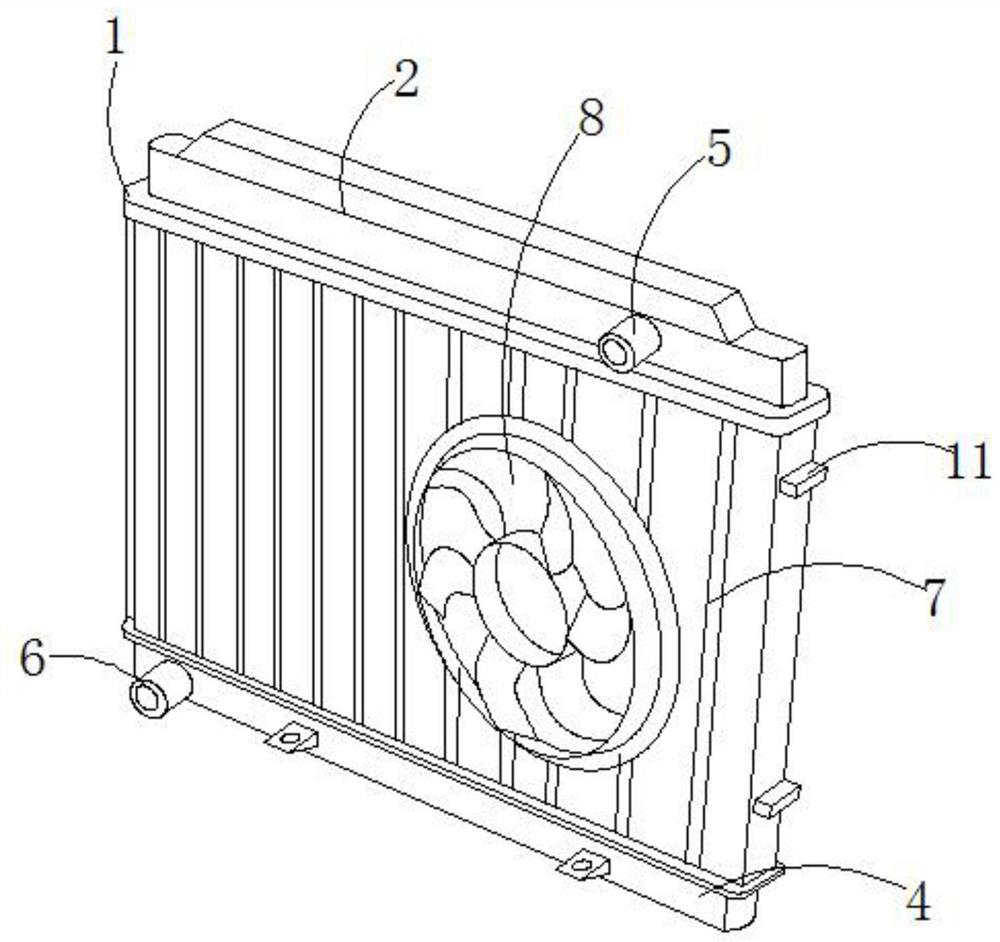

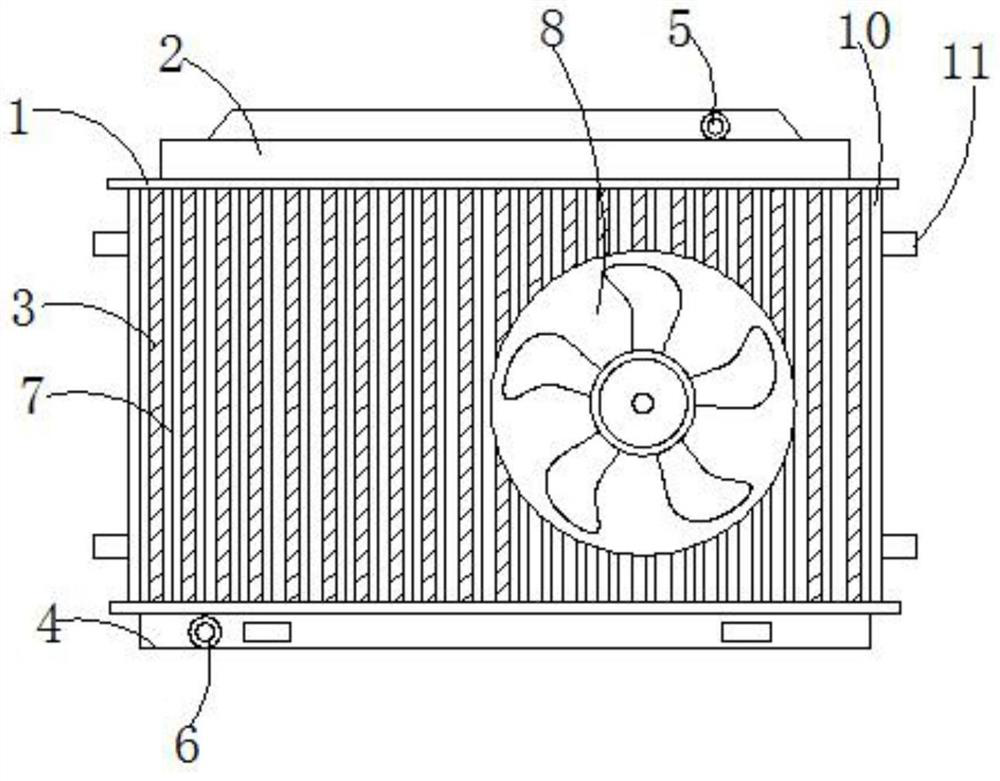

[0026] Such as Figure 1-4 As shown, a diesel engine radiator includes a frame 1, an upper water chamber 2, a cooling pipe 3 and a lower water chamber 4, the upper water chamber 2 is located at the upper end of the frame 1, and the upper side wall of the upper water chamber 2 is provided with The water inlet pipe 5 and the heat dissipation pipe 3 are located between the upper and lower racks 1, the lower water chamber 4 is fixedly installed at the lower end of the lower frame 1, and the side wall of the lower water chamber 4 is equipped with a water outlet pipe 6, and each adjacent two Radiating fins 7 are installed between the radiating pipes 3, cooling fans 8 are installed on the cooling fins 7, fixed plates 10 are installed on the left and right sides between the two racks 1 up and down, and the left and right two fixed plates 10 connect all the cooling pipes 3 sandwiched in the middle, the fixed pad 11 is fixedly installed on the fixed plate 10;

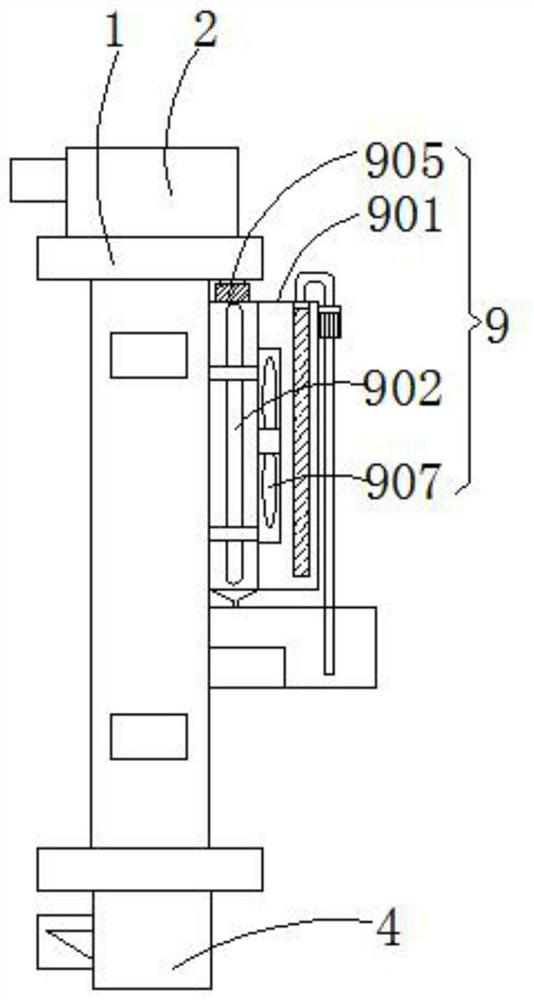

[0027] A temperature sen...

Embodiment 2

[0031] Such as Figure 1-5 As shown, a diesel engine radiator includes a frame 1, an upper water chamber 2, a cooling pipe 3 and a lower water chamber 4, the upper water chamber 2 is located at the upper end of the frame 1, and the upper side wall of the upper water chamber 2 is provided with The water inlet pipe 5 and the heat dissipation pipe 3 are located between the upper and lower racks 1, the lower water chamber 4 is fixedly installed at the lower end of the lower frame 1, and the side wall of the lower water chamber 4 is equipped with a water outlet pipe 6, and each adjacent two Radiating fins 7 are installed between the radiating pipes 3, cooling fans 8 are installed on the cooling fins 7, fixed plates 10 are installed on the left and right sides between the two racks 1 up and down, and the left and right two fixed plates 10 connect all the cooling pipes 3 sandwiched in the middle, the fixed pad 11 is fixedly installed on the fixed plate 10;

[0032]A temperature sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com