A system and method for detecting defects in electrical equipment using sweeping impulse current

A technology of inrush current and electrical equipment, applied in the field of electrical equipment defect detection, can solve problems such as narrow applicability, long detection time, limited spectrum coverage, etc., and achieve the effect of saving maintenance costs and improving defect detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

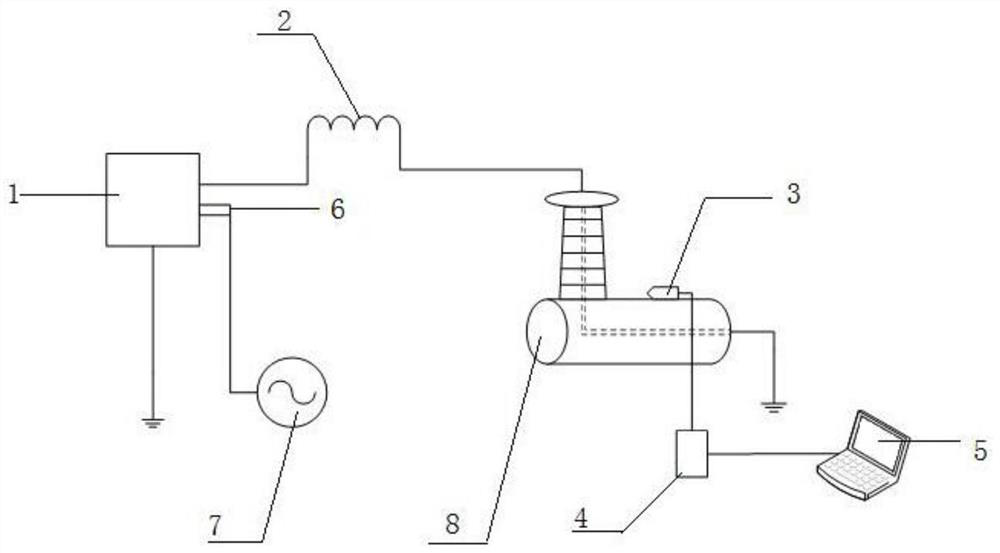

[0021] Such as figure 1 As shown, the system of the present invention includes an inrush current generator 1, an adjustable inductance 2, a vibration sensor 3, a data acquisition device 4, a vibration test system 5, a shunt 6 and an oscilloscope 7, and the output terminal of the inrush current generator 1 can be connected in series. After the inductance 2 is adjusted, it is connected to one end of the electrical equipment 8 to be tested, and the inrush current generator 1, the adjustable inductance 2, and the electrical equipment 8 are connected in series through a copper wire to form a loop; the inrush current generator 1 and the electrical equipment 8 are all connected to the ground; the inrush current The generator 1 is connected to the oscilloscope 7 through the shunt 6 to realize the monitoring of the discharge current waveform. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com