A position adjustment tracking device for a welding process monitoring platform spectrometer

A welding process and tracking device technology, applied in the direction of measuring devices, welding equipment, auxiliary devices, etc., can solve problems such as experimental errors, accurate monitoring of optical signals in difficult-to-weld areas, and optical signal differences, etc., to achieve repeated positioning, compact and novel structure , the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0037] Aiming at the problems that the adjustment process of the spectrometer placement position in the actual welding process is very complicated and time-consuming, accurate adjustment is difficult, the adjustment efficiency is low, and it is difficult to track the welding center, the invention provides a spectrometer position adjustment method for the welding process monitoring platform. tracking device.

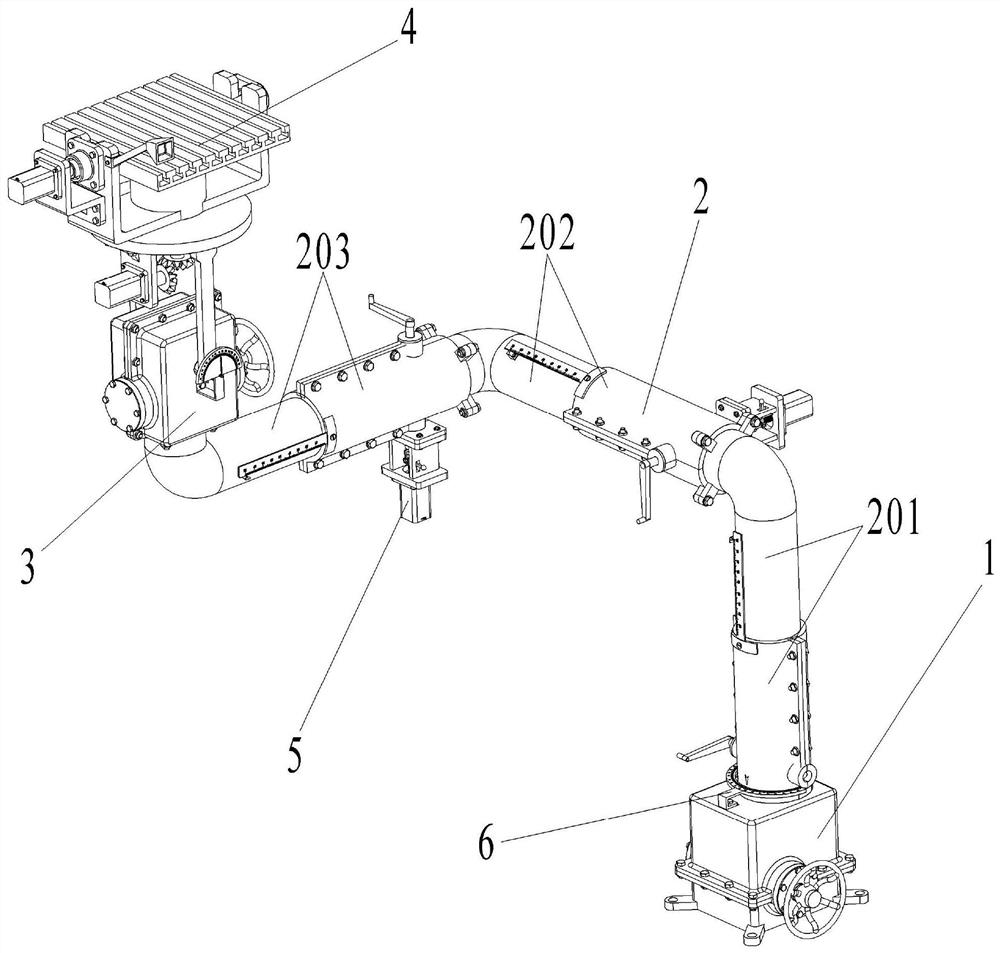

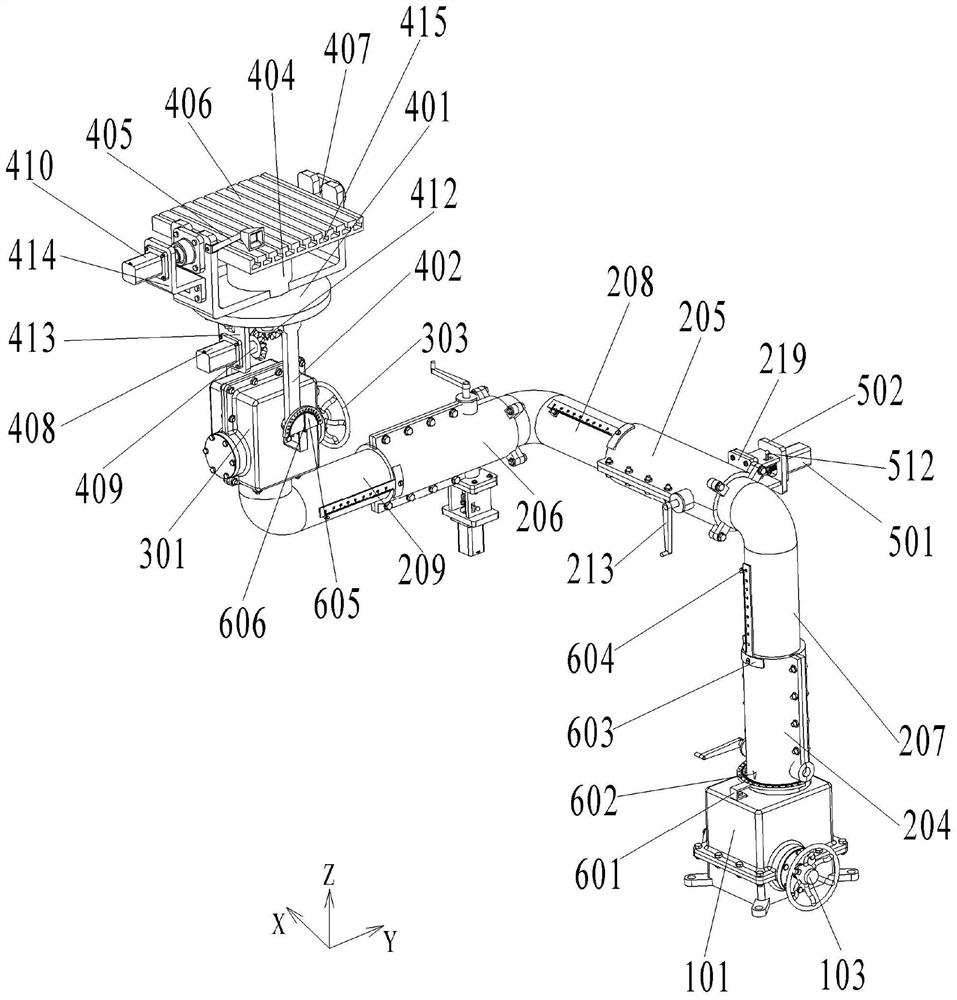

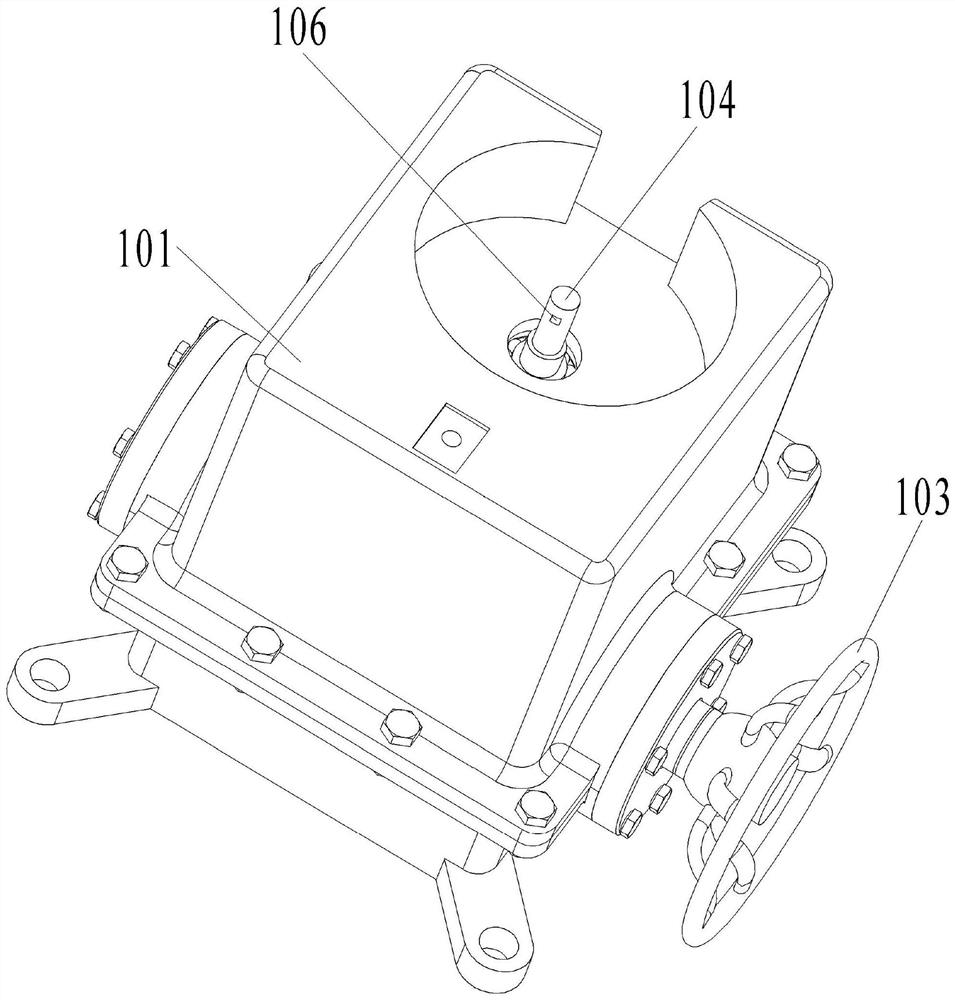

[0038] like Figure 1 to Figure 14 As shown, the embodiment of the present invention provides a position adjustment tracking device for a welding process monitoring platform spectrometer, including: a bottom angle adjustment assembly 1, the bottom angle adjustment assembly 1 includes an adjustment box 101, the adjustment box A bottom worm 102 is pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com