X-ray image classification and identification method for high-voltage strain clamp crimping defect discrimination

A tension clamp and image classification technology, applied in the field of inspection, can solve the problems of low judgment efficiency, accuracy cannot be separated from subjective factors, and time occupation is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

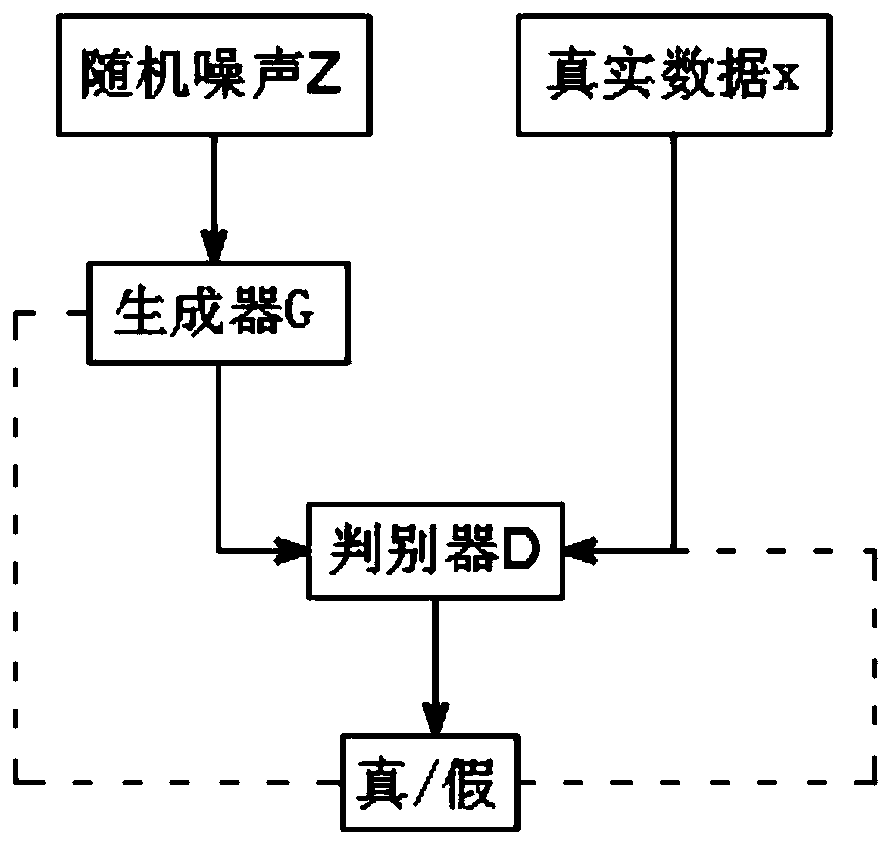

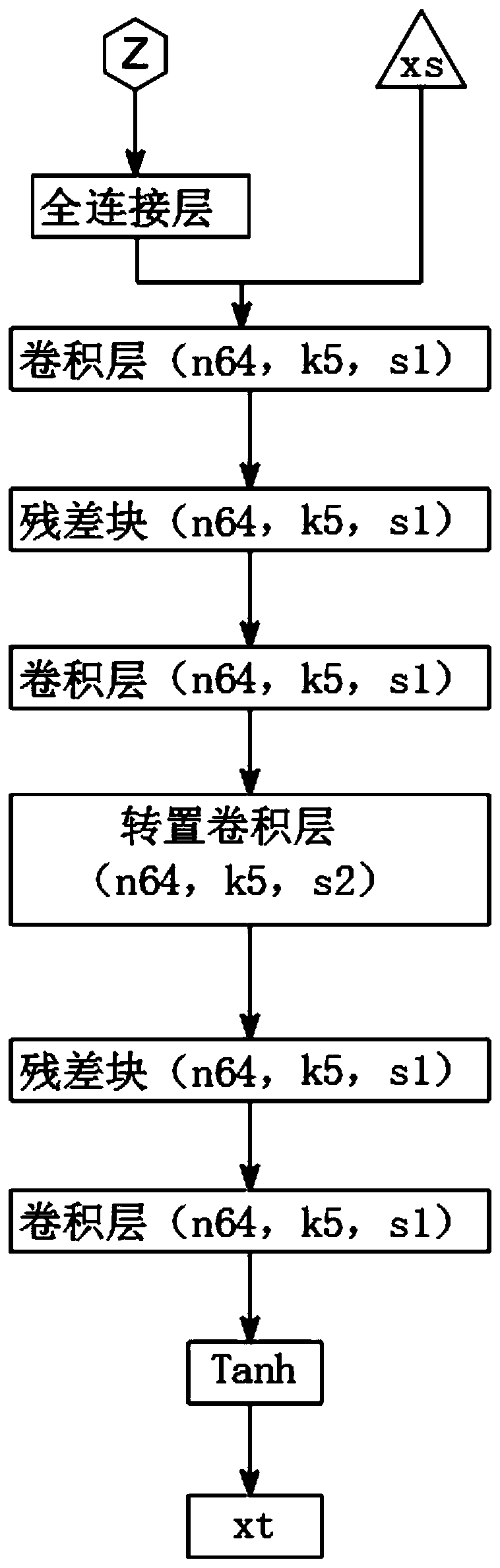

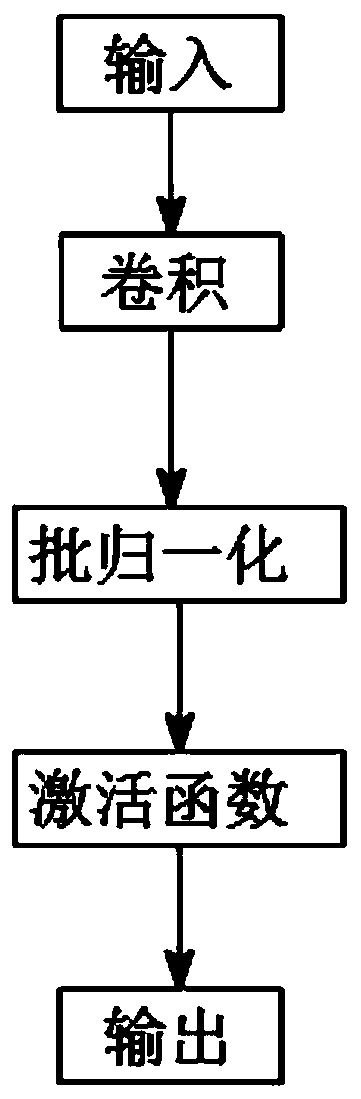

[0069] This embodiment uses a specific case to illustrate the detailed process of identifying existing X-ray-affected defects by using the X-ray image classification and recognition method for crimping defect discrimination of high-voltage tension clamps according to the present invention. Figure 1-6 As shown, the specific implementation includes the following steps:

[0070] Before using the method described in this application to judge whether any X-ray image or image of a tension clamp that needs to be judged exists, and if there is a defect, it needs to be established and trained for unknown GAN data model for discriminant X-ray images of defects in tension clamps. For the establishment and training of the GAN data model, the following steps are used to achieve:

[0071] Step S100 collects the X-ray images of existing strain clamp defects by category based on the type of strain clamp defect. The defect types cover all possible defect types of strain clamps, which are:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com