High-voltage output converter

A high-voltage output and converter technology, applied in the field of high-voltage output converters, can solve the problem of unsolved leakage inductance energy and other problems, and achieve the effects of reducing switching loss, power consumption, and reverse current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

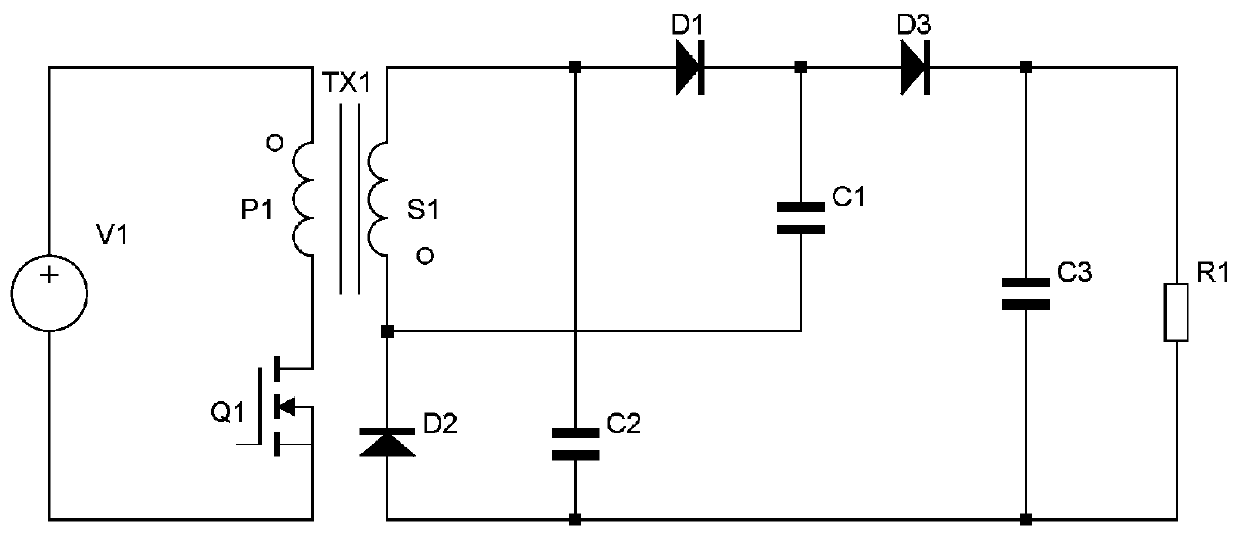

[0021] figure 2 It is a schematic diagram of the first embodiment of the switching converter power stage of the high-voltage output converter of the present invention, and the connection relationship of this embodiment is as follows:

[0022] The input positive terminal is electrically connected to the terminal with the same name of the primary winding P1 of the transformer TX1, the terminal with the same name of the primary winding P1 of the transformer TX1 is electrically connected to the drain of the MOS transistor Q1, the source of the MOS transistor Q1 is electrically connected to the input negative terminal, and the MOS The drain of the tube Q1 is also electrically connected to the source of the MOS tube Q2, the drain of the MOS tube Q2 is electrically connected to the positive terminal of the capacitor C4, the negative terminal of the capacitor C4 is electrically connected to the positive input terminal, and the secondary winding S1 of the transformer TX1 The opposite ...

no. 2 example

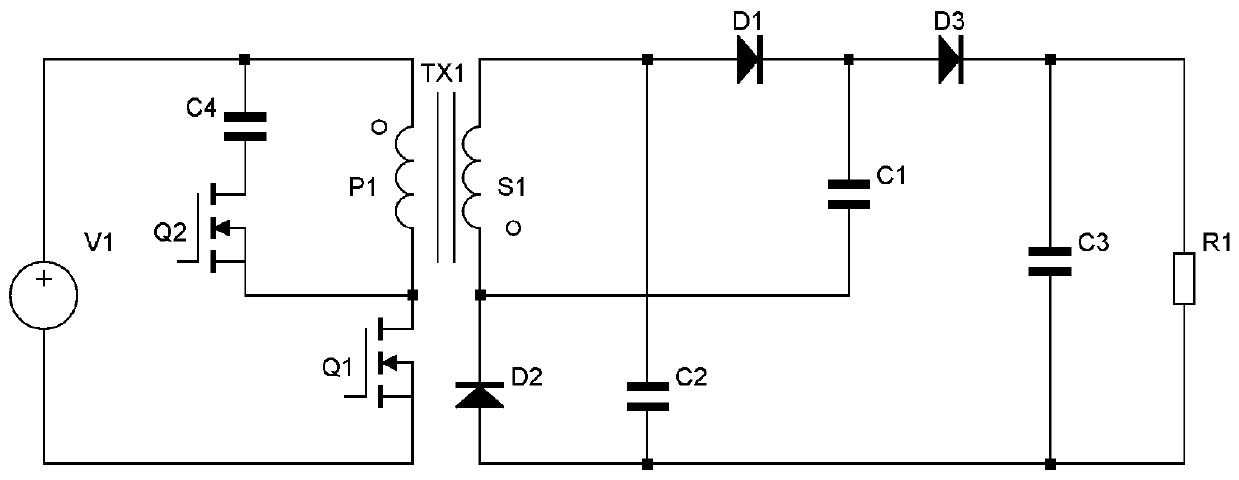

[0035] Figure 5 It is a schematic circuit diagram of a high-voltage output converter according to the second embodiment of the present invention. Wherein, compared with the first embodiment, the clamping circuit composed of MOS transistors and capacitors is not connected to the primary winding of the transformer, but is connected to the auxiliary winding. Since the clamp tube is connected to the auxiliary winding, its source voltage can be fixed, no bootstrap drive circuit is needed, and a conventional circuit (such as a totem pole circuit) can be used for driving, simplifying the drive circuit.

[0036] The connection relationship of this embodiment is as follows:

[0037] The input positive terminal is electrically connected to the same-named terminal of the primary winding P1 of the transformer TX1, the different-named terminal of the primary winding P1 of the transformer TX1 is electrically connected to the drain of the MOS transistor Q1, and the source of the MOS transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com