High-ground-clearance caterpillar self-propelled pineapple harvesting machine

A self-propelled, high-gap technology, applied to harvesters, loaders, agricultural machinery and implements, etc., can solve the problems of low production efficiency, harsh working conditions, and high labor intensity of fruits, and achieve high production efficiency and transition Convenient transportation and good passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

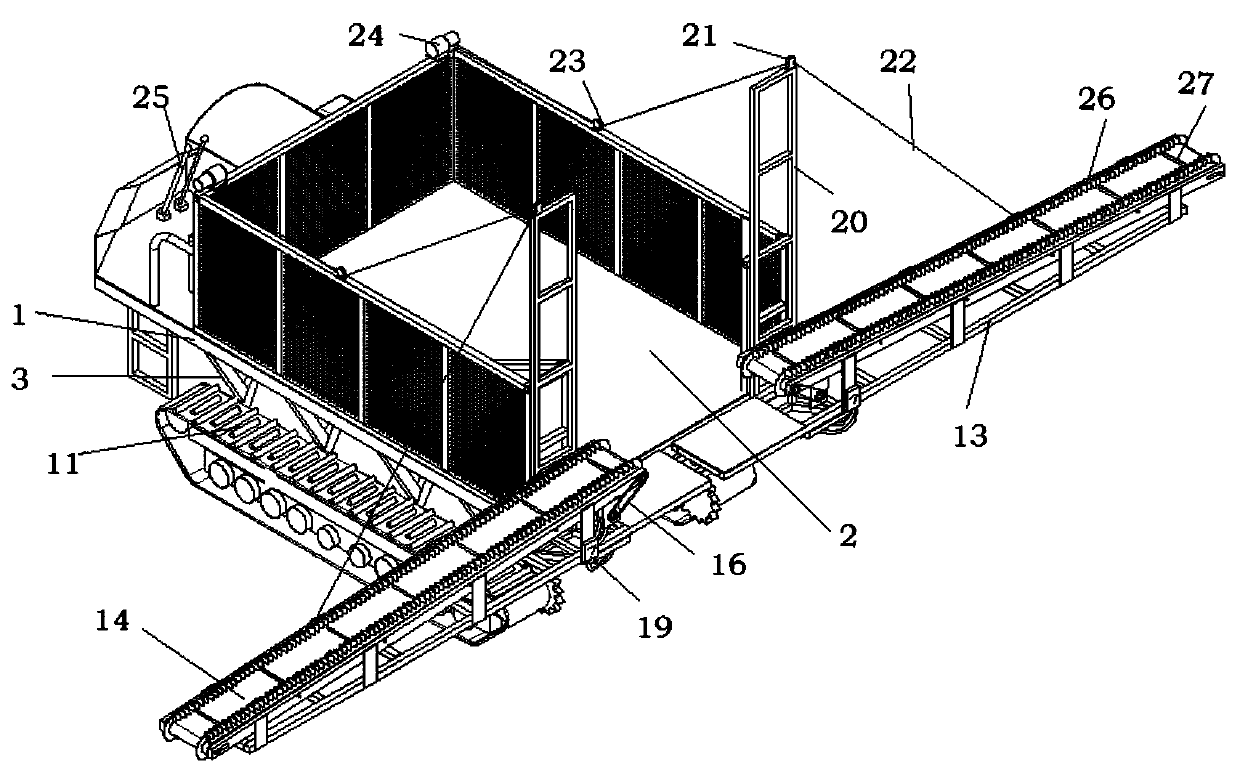

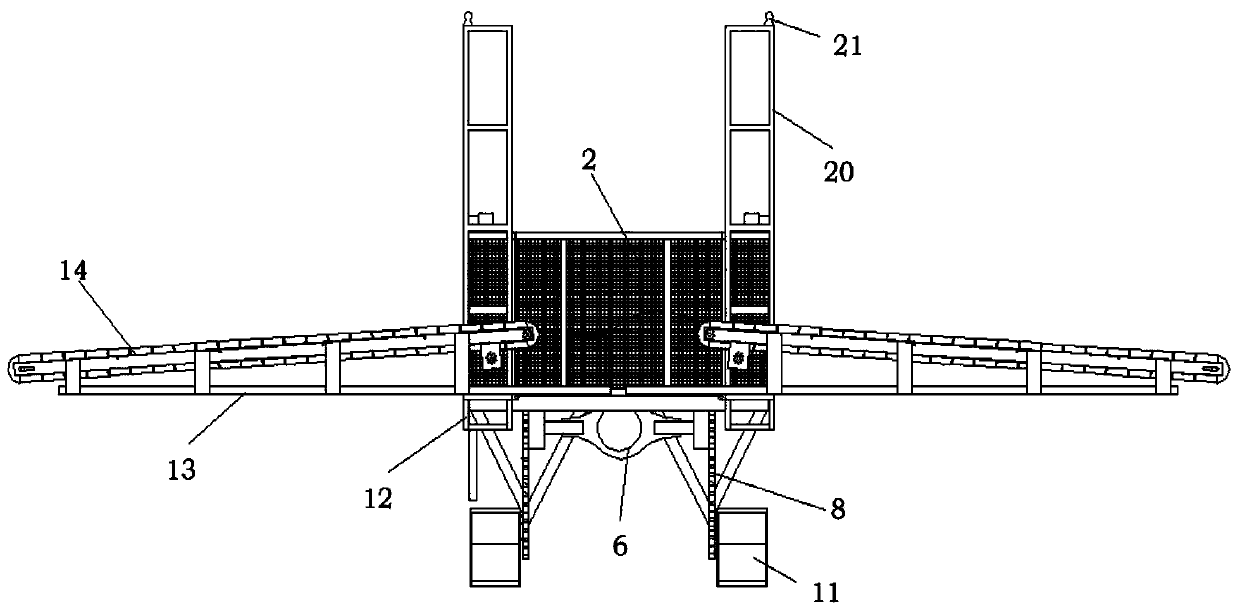

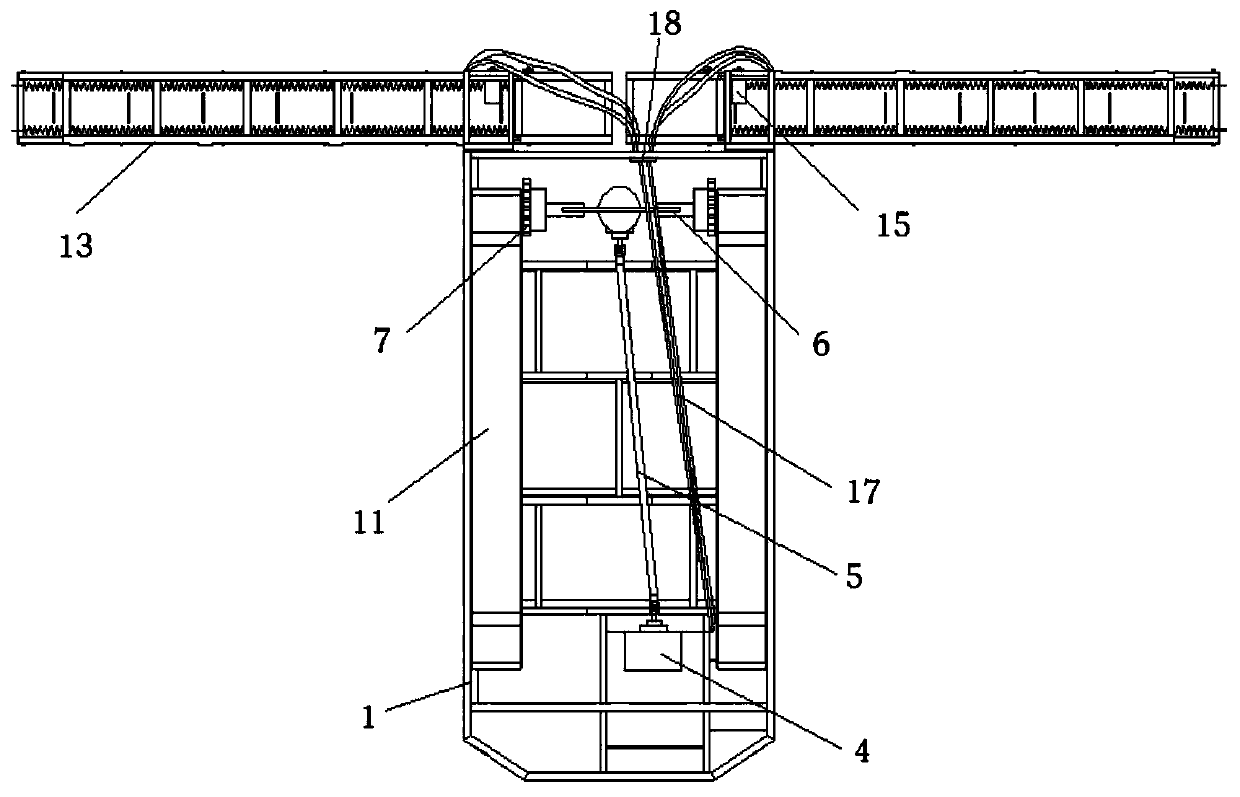

[0025] Such as figure 1 , 2 , 3 and 4, a high ground clearance crawler self-propelled pineapple harvesting vehicle, including crawler running gear, power system, walking platform 1, loading compartment 2, automatic retractable system, conveying device and hydraulic system, described The loading compartment 2 is fixedly welded on the top of the walking platform 1, and the walking platform 1 is provided with a crawler walking mechanism through the frame 3 on the bottom side thereof, and a power system is provided above the front part of the frame 3, and the power system The whole set of power and control of the diesel engine is adopted. The rear end beam of the loading compartment 2 is provided with a conveying device, and the conveying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com