A process method for strengthening the pressure resistance quality of aluminum alloy

A process method and aluminum alloy technology, applied in the field of aluminum alloy castings, can solve the problems of thermal joint dispersion, box casting leakage, small porosity and pinhole defects, and achieve the effect of improving the seepage effect and preventing pressure leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] Mix according to the requirements of the ingredients of the infusion solution, stir to make it even and fully wet, and the stirring time is not less than 1 hour.

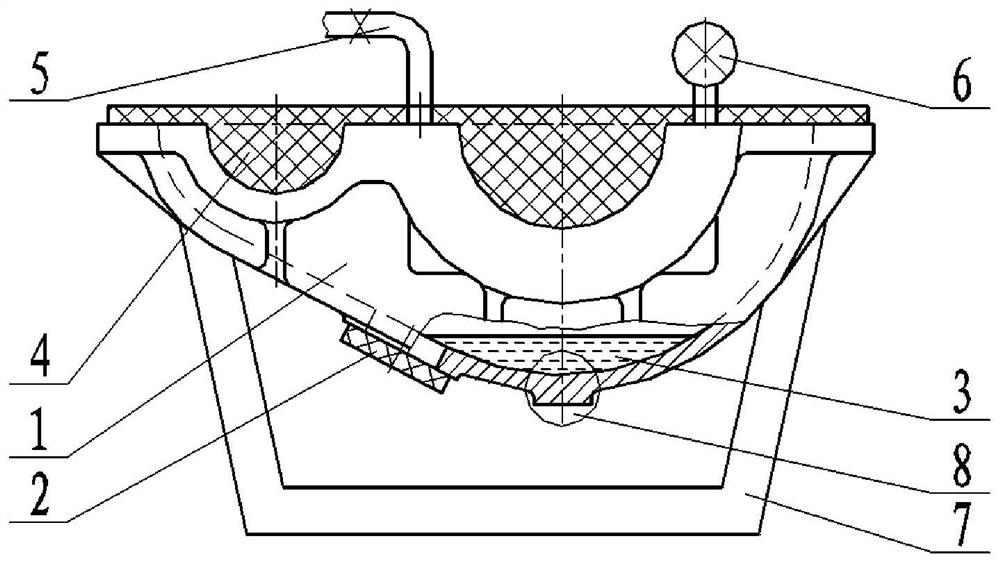

[0037] See the attachment for the schematic diagram of parts assembly figure 1 , after the casting 1 is finished, install the sealing side plate 2, add an appropriate amount of infiltration fluid 3 that is evenly stirred, install the sealing upper plate 4 on the casting 1, and reserve 2 processing holes on the sealing upper plate 4 to install valves. After the installation of the air inlet pipe 5 and pressure gauge 6 is completed, place the casting 1 on the test bench 7 to ensure that the leakage position 8 is at the deepest point of the liquid surface.

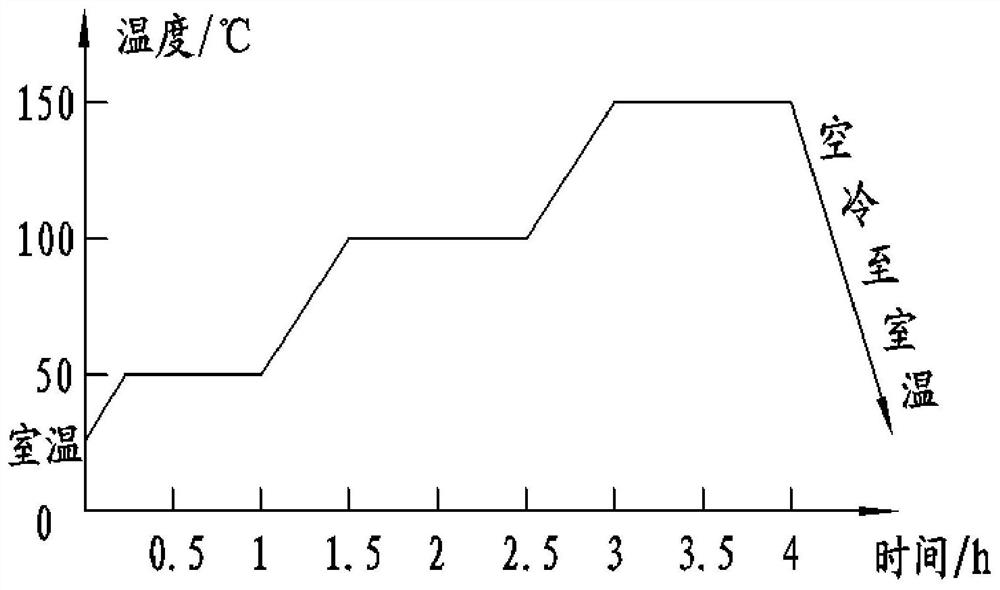

[0038] Fill compressed air through the inlet pipe 5 with a valve to make the inner cavity pressure of the casting 1 reach 0.48-0.50 MPa, close the valve, and maintain the pressure for 1-2 hours according to the degree of leakage. Remove the sealing upper pl...

Embodiment 3

[0041] Take the infiltration process of the reduction box as an example.

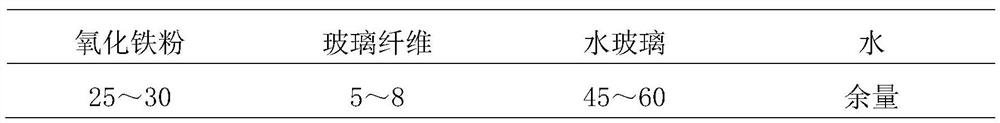

[0042] The embodiment is as follows: the raw material of the infiltration fluid is selected with a particle size of 20-25 μm Fe 2 o 3 Powder, 800-mesh glass fiber, water glass with a modulus M=3.1-3.3, and industrial distilled water are mixed according to the requirements of the infiltration fluid composition, stirred to make it even and fully wet, and the stirring time is 1 hour.

[0043] The schematic diagram of the assembly of the parts is shown in the attached figure 1 , after the casting 1 is finished, install the sealing side plate 2, add an appropriate amount of infiltration fluid 3 that is evenly stirred, install the sealing upper plate 4 on the casting 1, and reserve 2 processing holes on the sealing upper plate 4 to install valves. After the installation of the air inlet pipe 5 and pressure gauge 6 is completed, place the casting 1 on the test bench 7 to ensure that the leakage position 8 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com