Shifting fork plane machining equipment

A plane and equipment technology, applied in the field of shift fork plane workbench equipment, can solve the problems of low machining accuracy, troublesome and low production efficiency of parts, and achieve the effects of improving work efficiency, convenient operation and shortening work steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

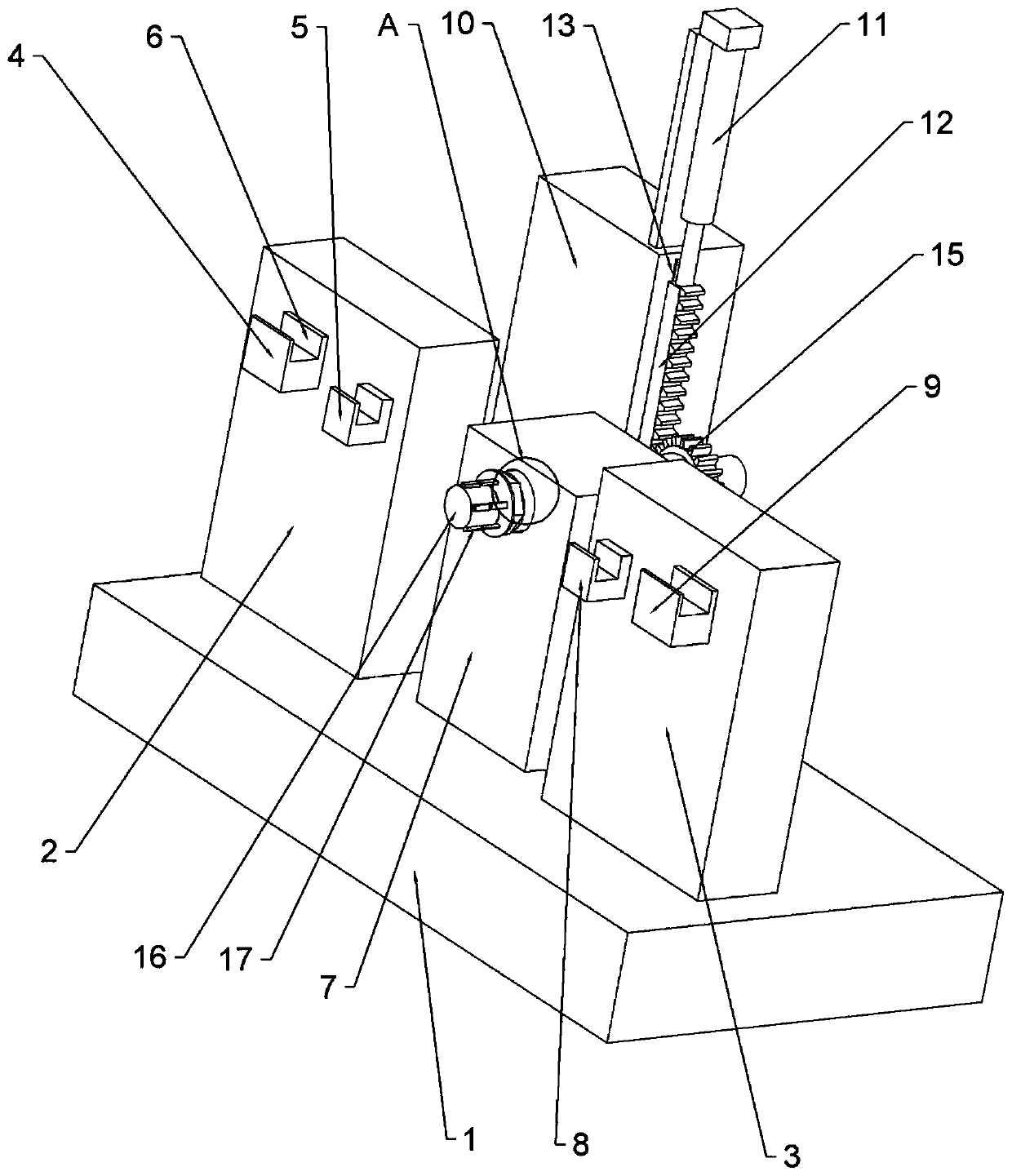

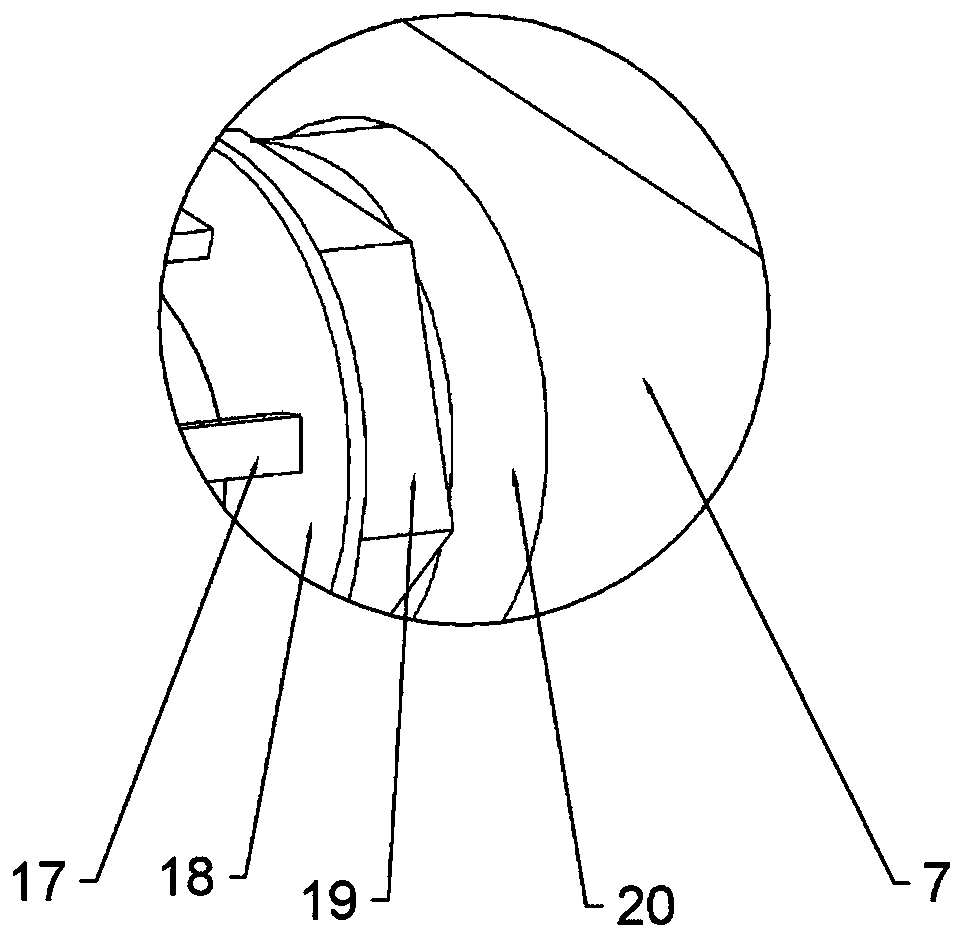

[0025] This embodiment is basically as attached Figure 1-Figure 4 Shown: a fork plane machining equipment, including a workbench 1 and a milling machine (not shown). The milling machine is a milling machine in the prior art, and its structure and usage are known to those skilled in the art, and will not be described in detail here. The upper end surface of the workbench 1 is provided with the first vertical plate 2, the fixed plate 7 and the second vertical plate 3 in sequence, and the connection mode between the first vertical plate 2, the second vertical plate 3 and the fixed plate 7 and the workbench 1 can be clamping , welded or connected by screws, etc. The end of the first vertical plate 2 is provided with a first support portion for supporting the lower end surface of the shift fork; the first support portion includes a first support block 5 and a first positioning block 4 . Both the first supporting block 5 and the first positioning block 4 are fixed on the end surf...

Embodiment 2

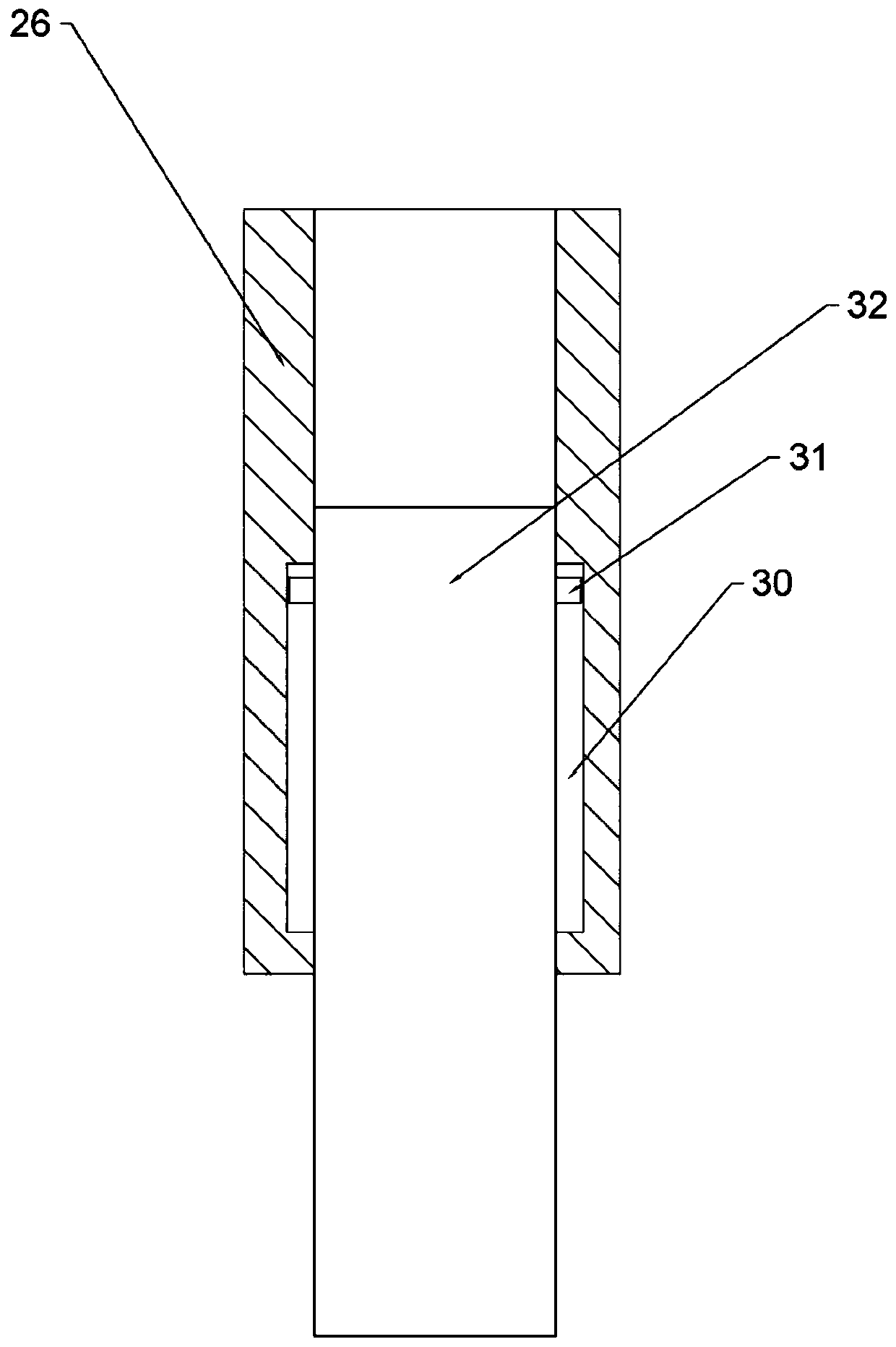

[0033] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a limiting plate 25, which is fixedly connected to the bracket 10, and the connection method can be welding or clamping. A through hole is opened in the middle of the limiting plate 25, and the end of the fixing column 16 away from the fixing part passes through the through hole. The side wall of the part of the fixing column 16 positioned in the through hole has a groove 22, and the side wall of the through hole has a limit groove 30, and a limit pin 14 and a spring 23 are arranged in the limit groove 30, and the two ends of the spring 23 are respectively connected with the limit groove. The bottom wall of the groove 30 and the end of the limit pin 14 are connected by screws. The left end of the limit pin 14 is hemispherical and the left end of the limit pin 14 can extend into the groove 22 .

[0034] Under natural circumstances, the left end of t...

Embodiment 3

[0036] Such as Figure 6 As shown, the difference between this embodiment and the second embodiment is that this embodiment also includes an air blowing structure for blowing air to the shift fork. The air blowing structure comprises an elastic bellows 21 (also can be a foot pump), and the lower end of the elastic bellows 21 is bonded to the upper end of the workbench 1 . The elastic bellows 21 is connected with an air blowing pipe (not shown in the figure), and the air outlet end of the air blowing pipe faces the first supporting part. The present embodiment also includes a one-way air inlet valve and a one-way air outlet valve (not shown in the figure), the elastic bellows 21 has an air inlet, and the one-way air inlet valve is arranged at the air inlet of the elastic bellows 21 . The one-way air outlet valve is arranged at the joint between the elastic bellows 21 and the air blowing pipe. Both the one-way inlet valve and the one-way outlet valve are prior art, and their s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com