Welding robot energy optimization method based on welding gun rotation angles

A welding robot and energy optimization technology, which is applied to welding accessories, electrode characteristics, electrode support devices, etc., can solve problems such as inaccurate energy consumption, difficulty in obtaining robot models, and complex calculations, and achieve simple data processing methods and broaden energy optimization. The effect of simple method and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

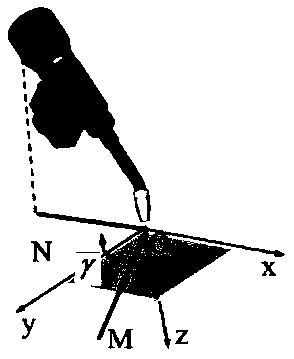

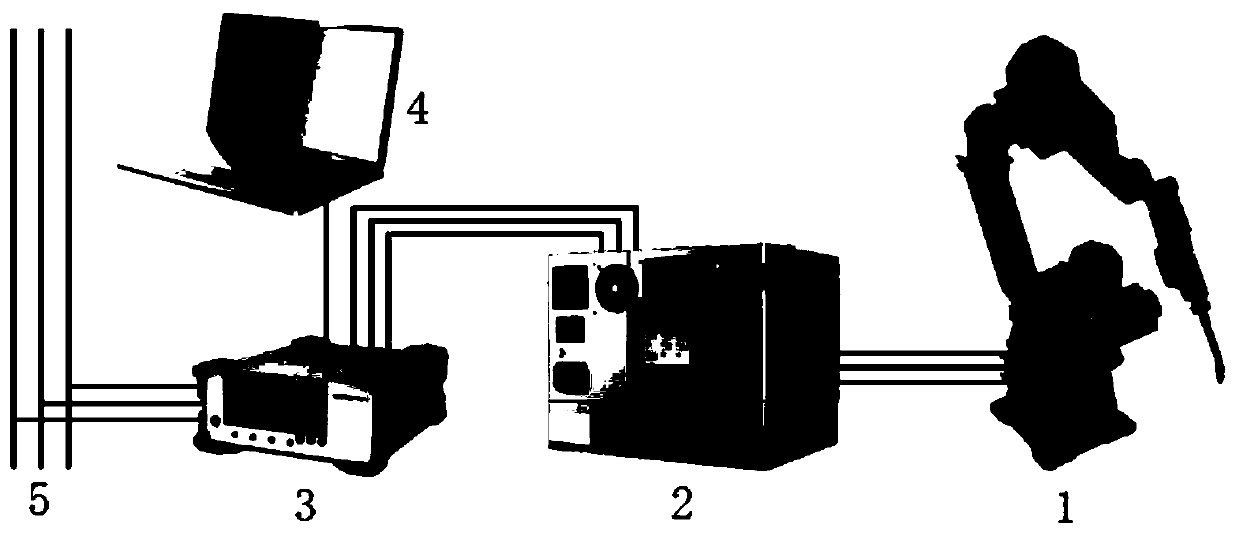

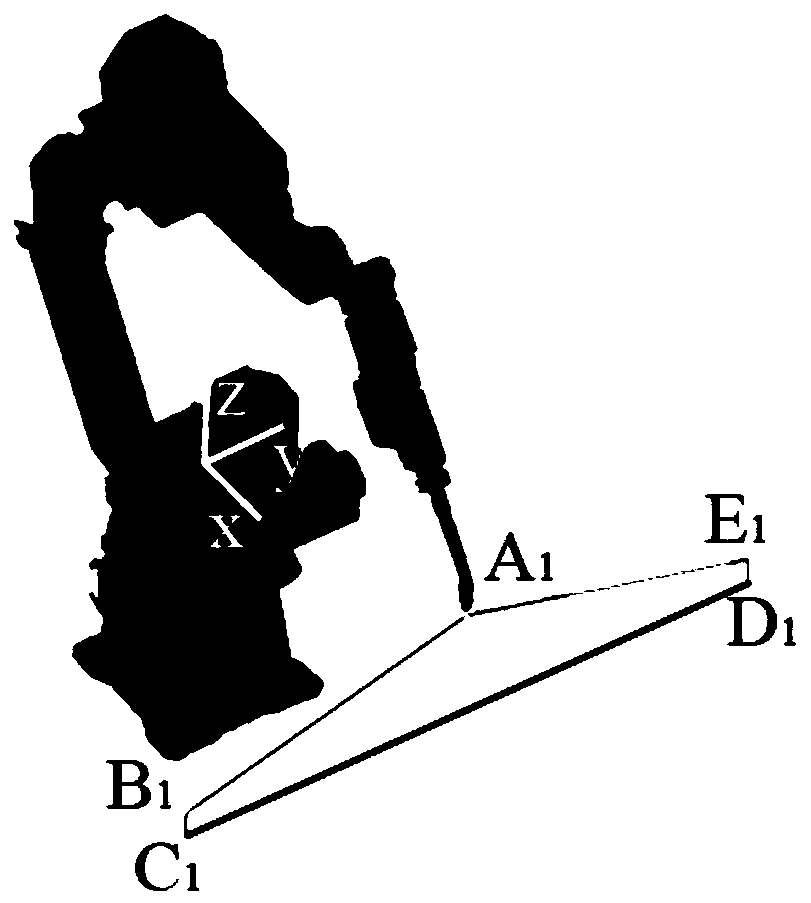

[0040] Before studying this energy optimization method, the definition of the torch rotation angle of the arc welding robot is given first. as attached figure 1 As shown, the tool coordinate system is a coordinate system established with the tool center point as the origin, and is a rectangular coordinate system used to represent the tool center point and tool posture. In the arc welding robot 1, the origin O of the tool coordinate system is generally defined at the place where the welding wire protrudes 10mm from the contact tip, the z-axis of the tool coordinate system is defined as the axial direction of the welding torch (that is, the direction in which the welding wire protrudes), and the rotation angle of the welding torch is defined as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com