Method for repairing various welding seam defects of laser welding of power battery sealing nails

A laser welding and power battery technology, applied in laser welding equipment, welding equipment, battery pack components, etc., can solve the problems of cell voltage resistance and sealing performance failure, cell scrapping, etc., to repair welding seam defects, Low cost and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for repairing multiple defects of power battery sealing nail laser welding, the steps are as follows:

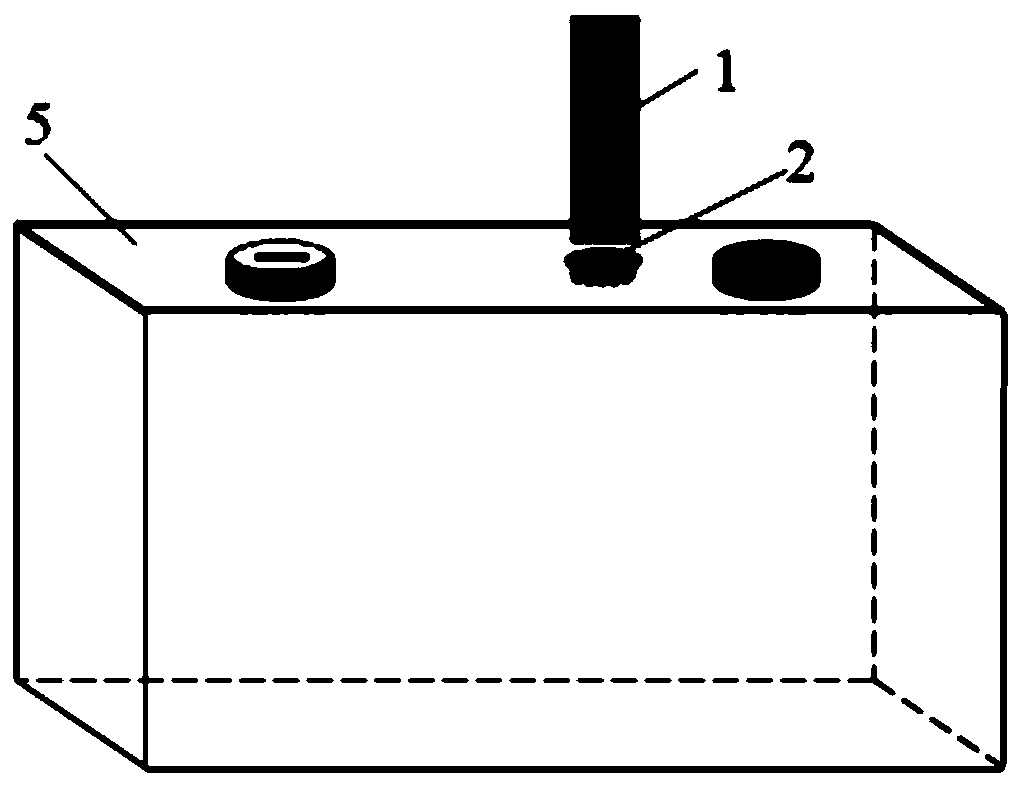

[0035] Step 1. Use a Φ7mm milling cutter to mill grooves at the pinhole position of the original sealing aluminum nail and the welding seam of the cell top cover. The milling cutter sinks 0.8mm to remove the defective weld seam;

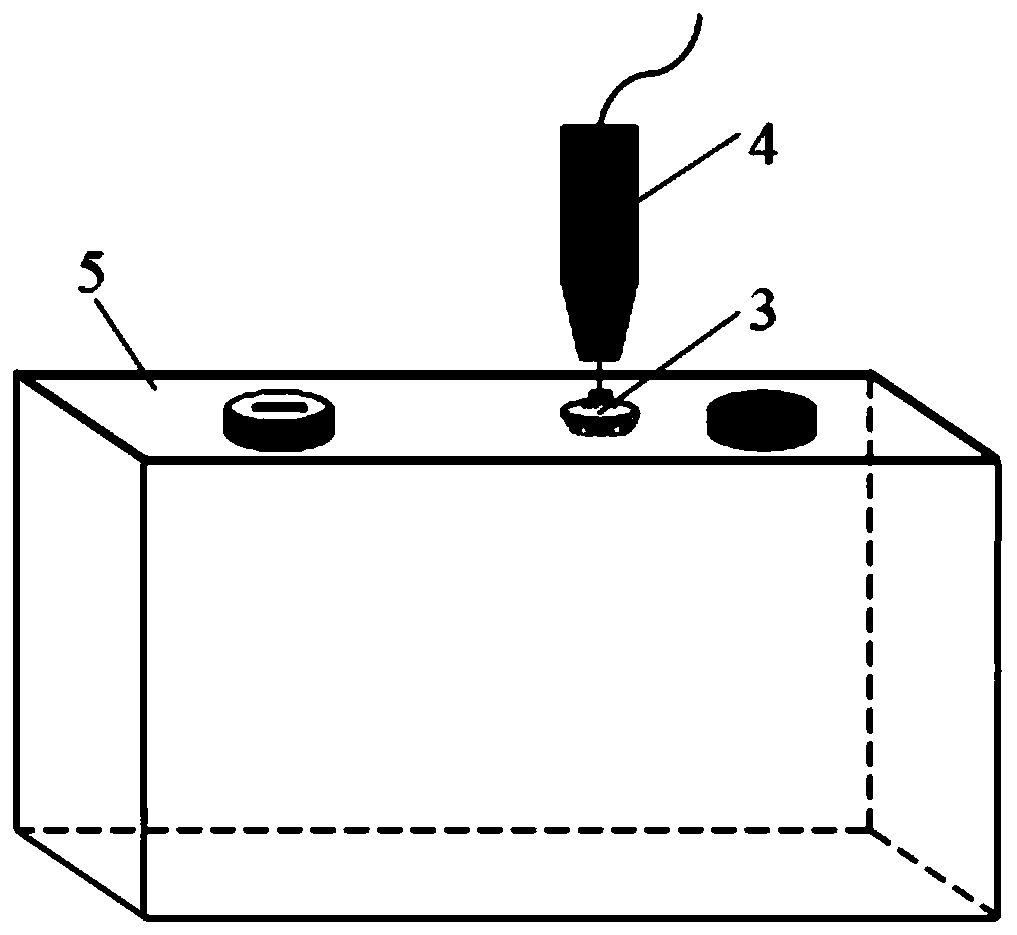

[0036] Step 2, use alcohol and a metal brush to clean the milled groove comprehensively, first clean the milled groove 3 with a metal brush, and then wipe the groove 3 with alcohol; preferably, a metal brush is an electric metal brush;

[0037] Step 3. Use a 40w laser to clean the surface of the groove at 1200mm / s;

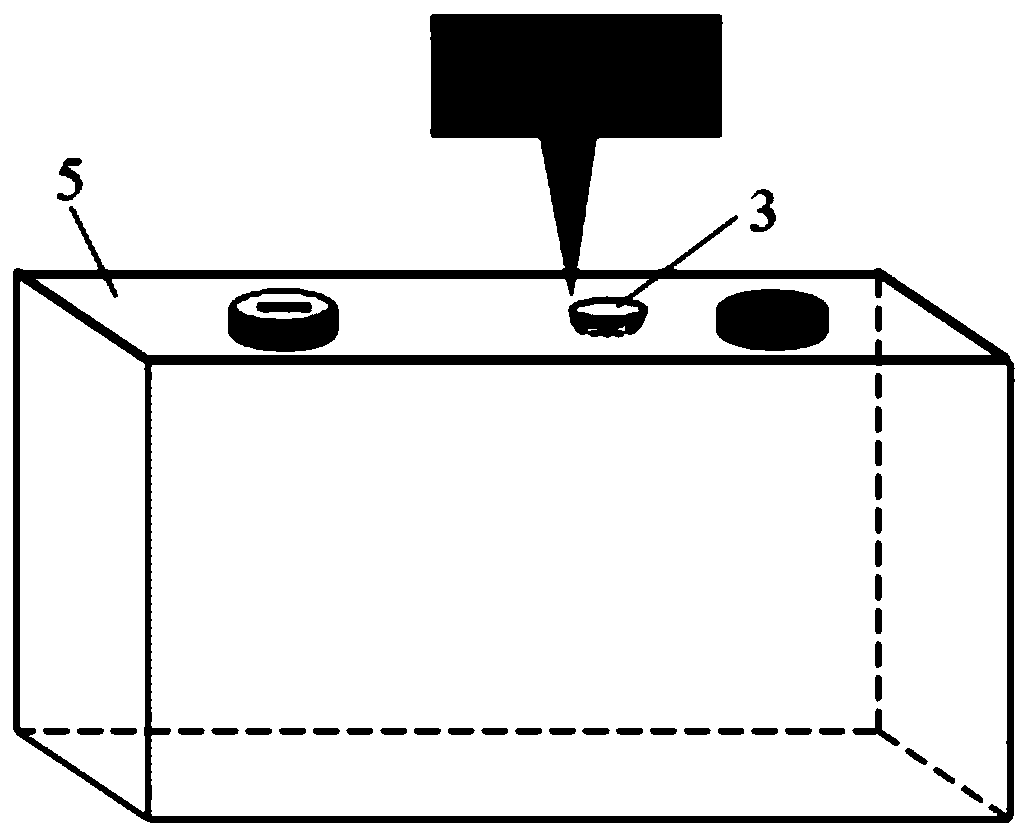

[0038] Step 4. Put the custom-made new aluminum nail with a diameter of 7mm and a thickness of 0.8mm into the milled groove, and then put the battery into the laser welding equipment, with a power of 6.3kW and a welding speed of 6mm / s, +0.3mm The amount of defocus, laser sealing welding is performed again.

Embodiment 2

[0040] A method for repairing multiple defects of power battery sealing nail laser welding, the steps are as follows:

[0041] Step 1. Use a Φ8mm milling cutter to mill grooves on the original sealing aluminum nail and the weld pit of the top cover. The milling cutter sinks 0.7mm to remove the defective weld;

[0042] Step 2, use alcohol and a metal brush to clean the milled groove comprehensively, first clean the milled groove 3 with a metal brush, and then wipe the groove 3 with alcohol; preferably, a metal brush is an electric metal brush;

[0043] Step 3. Use a 38w laser to clean the surface of the groove at 1100mm / s;

[0044] Step 4. Put the custom-made new aluminum nail with a diameter of 8mm and a thickness of 0.7mm into the milled groove, and then put the battery into the laser welding equipment, with a power of 6.5kW and a welding speed of 6mm / s, +0.4mm The amount of defocus, laser sealing welding is performed again.

[0045] The invention removes the original defe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com