Independent suspension mechanism for AGV and heavy-load AGV

A technology of independent suspension and swing rod, which is applied to suspensions, motor vehicles, elastic suspensions, etc., can solve the problems of unstable movement of the main body of the frame, the deviation of the robot from the predetermined route, and difficulty in motion control, and achieves simple structure and fast vibration. Attenuation, effect of low frame body height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

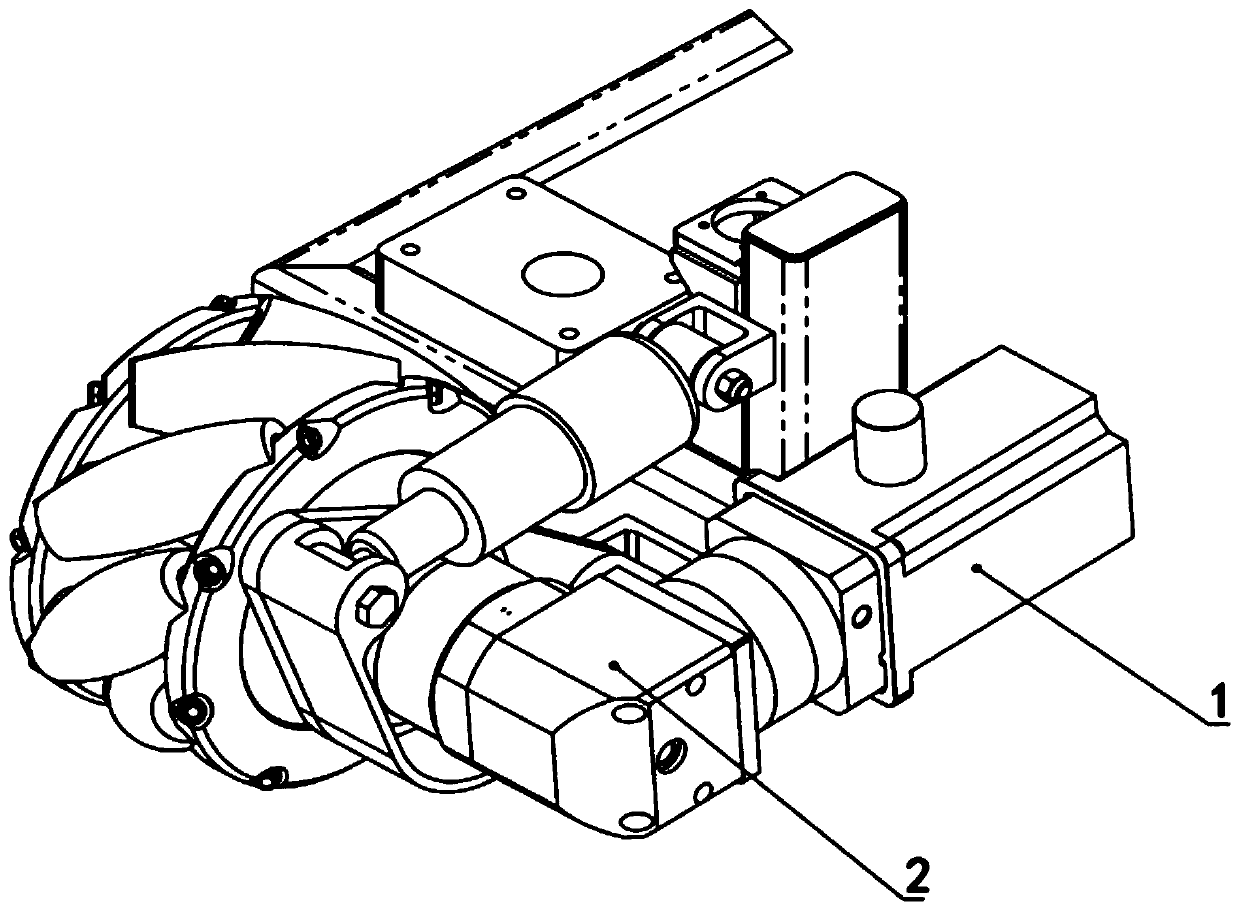

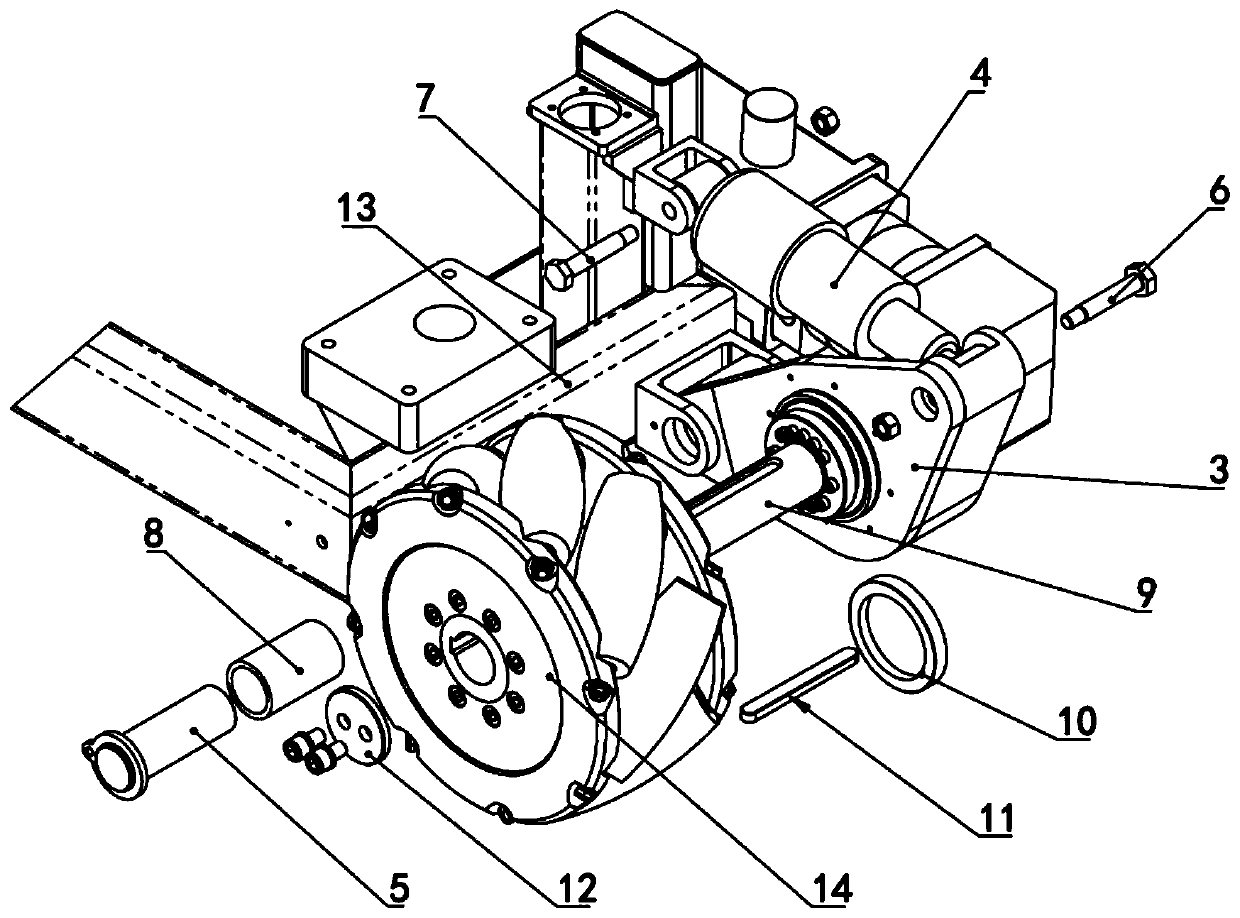

[0027] In one or more embodiments, an independent suspension mechanism for AGV is disclosed, referring to figure 1 and figure 2 , including: a drive motor 1, a reducer 2, a shock absorber 4 and a swing rod 3; the drive motor 1 is connected to the reducer 2; the output end of the reducer 2 is connected to the transmission shaft 9. The drive shaft 9 is connected to the wheel; one end of the shock absorber 4 is connected to the frame body 13, and the other end is hinged to one end of the swing rod 3; the swing rod 3 is sleeved on the drive shaft 9 and can rotate around the drive shaft 9 ; The other end of the swing rod 3 is hinged with the frame body 13 .

[0028] In consideration of reducing the height of the frame body 13 , the shock absorber 4 is in a horizontal state under the condition of bearing the normal weight of the frame body 13 .

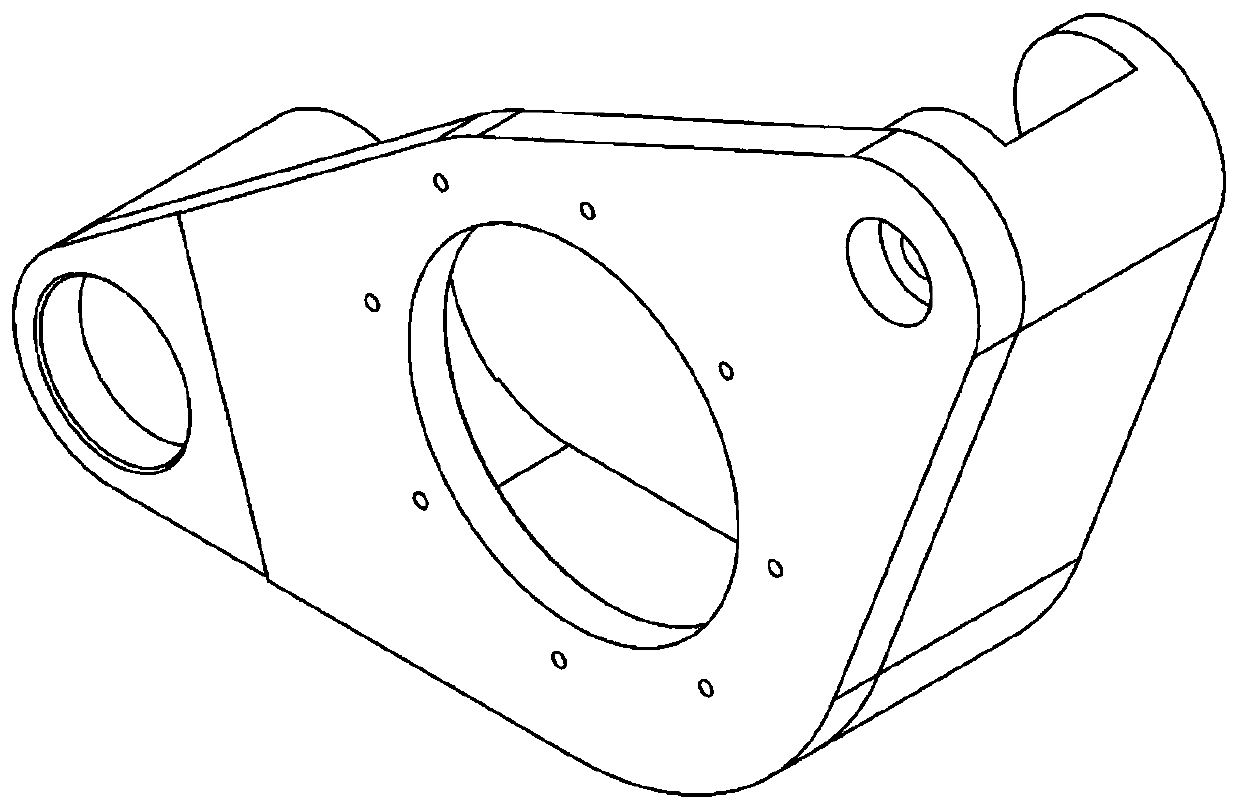

[0029] Structural reference of swing rod 3 image 3 The middle position of the swing rod 3 is provided with a through hole for passing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com