Light lead screw lifting mechanism

A screw lift and screw technology, applied in the field of robots, can solve the problems of low resistance to external interference, high rigidity of the lifting bucket itself, low overall reliability, etc., and achieve the effects of light weight, small overall size, and large lifting stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

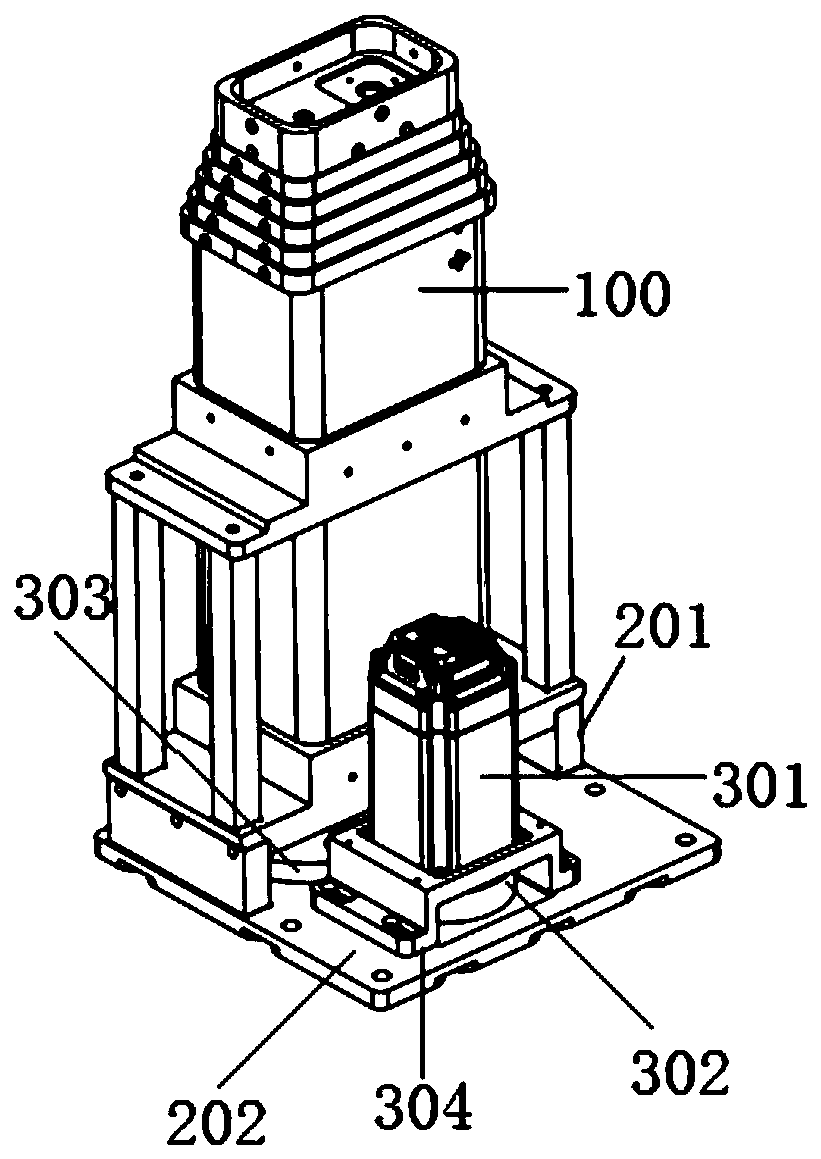

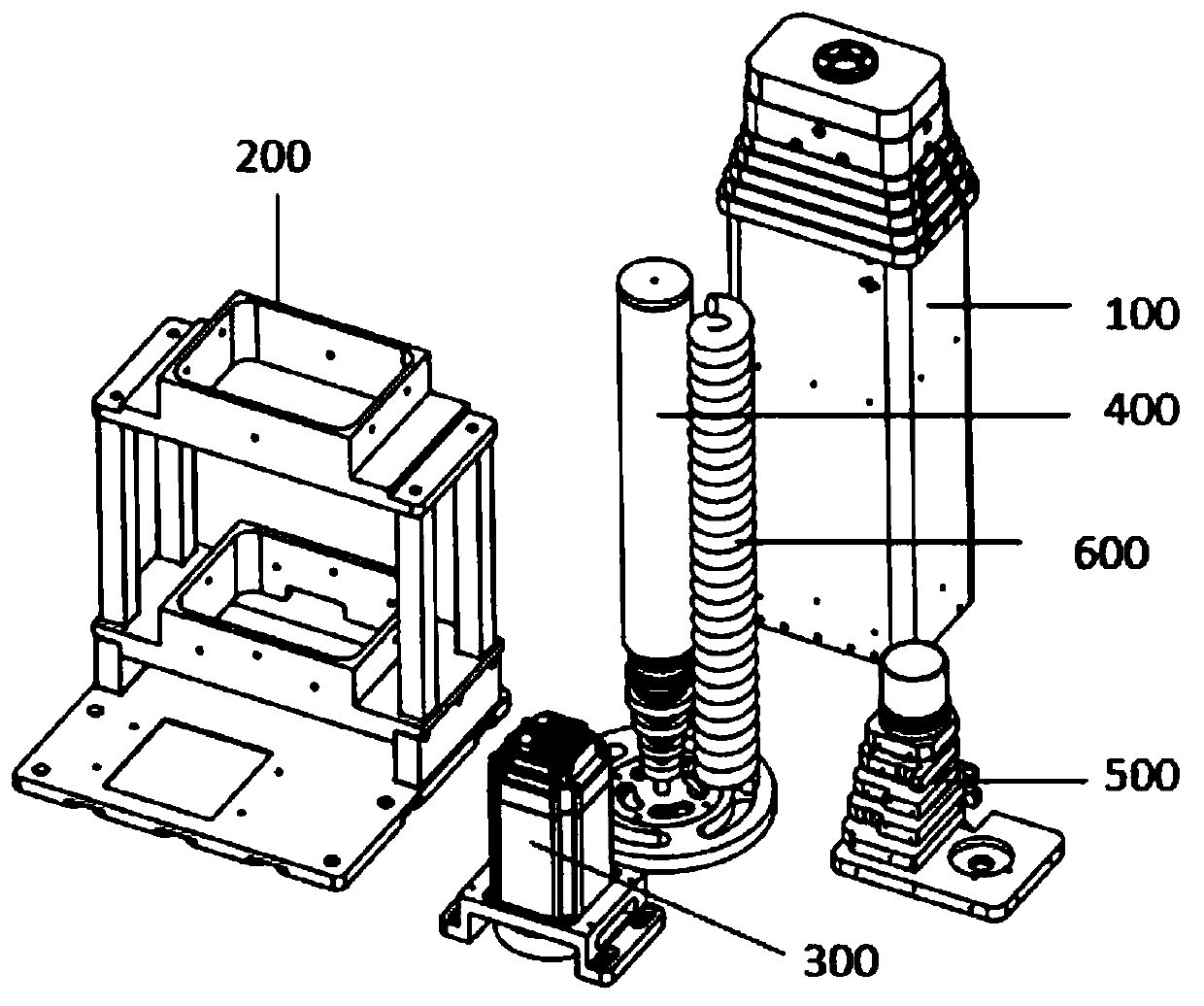

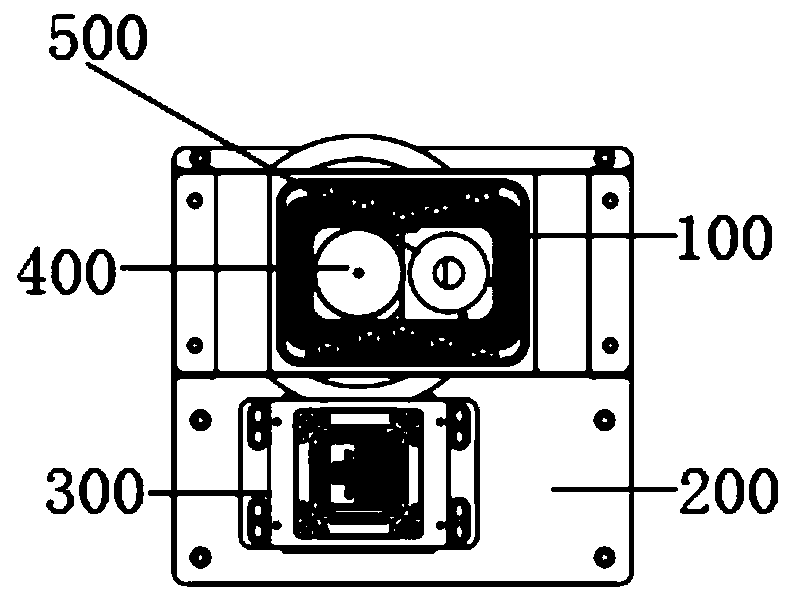

[0038] Such as Figure 1-Figure 3 A light-duty screw lifting mechanism shown includes a lifting barrel module 100 , a driving module 300 , a screw module 400 and a connecting module 500 . This embodiment takes 6 lifting barrels as an example to introduce the light-duty screw-screw lifting mechanism of the present invention. The screw module 400 is installed in the main body of the lifting bucket module, the screw module 400 and the main body of the lifting bucket module are connected through the connection module 500, and the driving module 300 and the main body of the lifting bucket module are fixed together on the fixing frame 200 of the lifting bucket. The motor 301 in the driving module 300 transmits power to the screw module 400 through two transmission gears (the first transmission gear 302 and the second transmission gear 303 ), and the rotation of the screw rod dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com