Comb polyurethane lubricant and water-based drilling fluid

A polyurethane and lubricant technology, applied in the field of oil drilling, can solve the problems of few adsorption anchor points, difficulty in meeting the design requirements for lubrication effect, and inability to form a strong adsorption film, so as to improve the strength of the extreme pressure film and improve the stability of cycle use , long-lasting effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

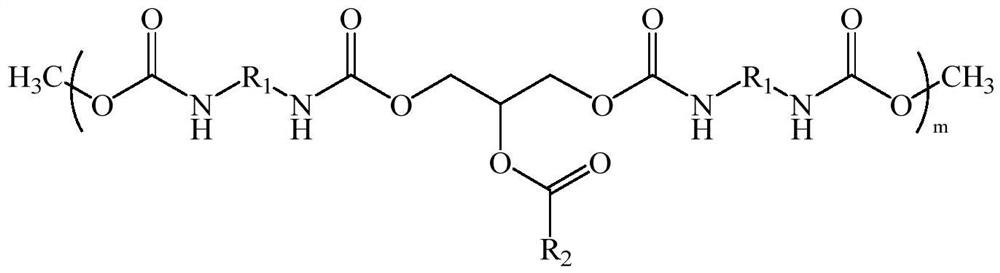

Method used

Image

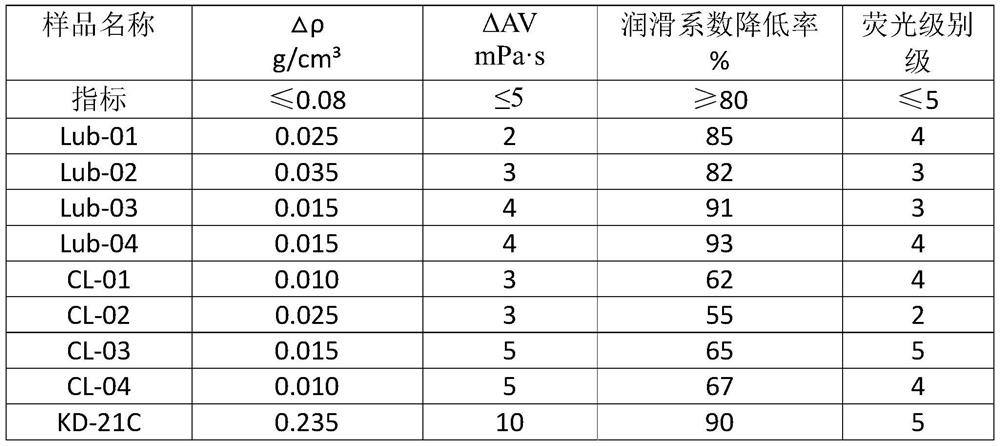

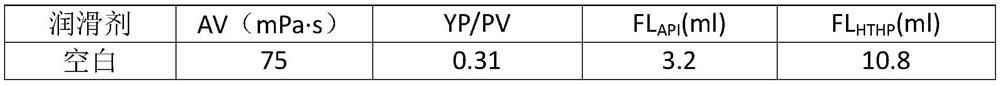

Examples

Embodiment 1

[0025] A kind of comb polyurethane lubricant, it is prepared by following method:

[0026] S1. Weigh 1.5 mol of diisocyanate A (O=C=N-(CH 2 ) 4 -N=C=O) and 1mol of coconut oil monoglyceride; then diisocyanate A is added to the reaction flask and the temperature is raised to 70°C, and under stirring, coconut oil fatty acid monoglyceride is added dropwise to the reaction flask In, continue constant temperature stirring 10h, obtain unblocked polyurethane;

[0027] S2. Increase the reaction temperature to 110° C., drop excess 3 mol of methanol into the reaction product obtained in step S1, continue stirring at constant temperature for 6 hours after the dropwise addition, and then naturally cool to room temperature to obtain a methyl-terminated polyurethane crude product;

[0028] S3. Carrying out rotary evaporation under reduced pressure on the crude polyurethane product obtained in step S2 to remove unreacted methanol to obtain comb-shaped ester-soluble polyurethane; after test...

Embodiment 2

[0031] A kind of comb polyurethane lubricant, it is prepared by following method:

[0032] S1. Weigh 1.6 mol of diisocyanate B (O=C=N-(CH 2 ) 6 -N=C=O) and 1 mol of soybean oleic acid monoglyceride; then diisocyanate B was added to the reaction flask and the temperature was raised to 80°C, and under stirring conditions, coconut oil fatty acid monoglyceride was added dropwise to the reaction flask In, continue constant temperature stirring 5h, obtain unblocked polyurethane;

[0033] S2. Increase the reaction temperature to 120° C., drop excess 2.8 mol of methanol into the reaction product obtained in step S1, continue stirring at a constant temperature for 4 hours after the addition is completed, and then naturally cool to room temperature to obtain a methyl-terminated polyurethane crude product ;

[0034] S3. Rotate the crude polyurethane product obtained through step S2 to remove unreacted methanol to obtain comb-shaped ester-soluble polyurethane; after testing, the number...

Embodiment 3

[0037] A kind of comb polyurethane lubricant, it is prepared by following method:

[0038] S1. Weigh 1.5 mol of diisocyanate C (O=C=N-(CH 2 ) 8 -N=C=O) and 1mol rapeseed monoglyceride; then diisocyanate C is added to the reaction flask and the temperature is raised to 90°C, and under stirring, coconut oil fatty acid monoglyceride is added dropwise to the reaction flask In the bottle, continue stirring at constant temperature for 4 hours to obtain unblocked polyurethane;

[0039] S2. Increase the reaction temperature to 120° C., drop an excess of 3.8 mol methanol into the reaction product obtained in step S1, continue to stir at a constant temperature for 5 hours after the dropwise addition, and then naturally cool to room temperature to obtain a methyl-terminated polyurethane crude product ;

[0040] S3. Carrying out rotary evaporation under reduced pressure on the crude polyurethane product obtained in step S2 to remove unreacted methanol to obtain comb-shaped ester-solubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com