A kind of oil well cement defoamer, preparation method and application

An oil well cement and oil well cement slurry technology, applied in the field of drilling, can solve the problems of low effective components, limited defoaming ability, single function, etc., and achieve the effects of obvious foam suppression effect, obvious defoaming effect and wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

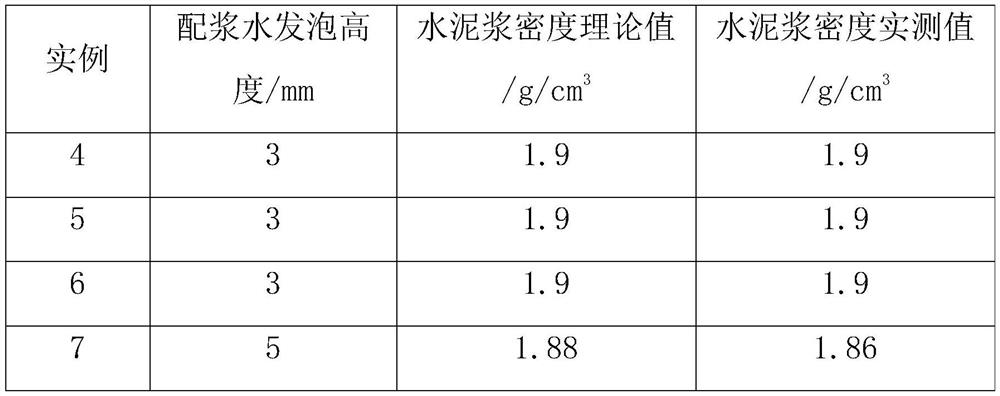

Examples

preparation example Construction

[0036] Preparation of Nail Cream:

[0037] Viscosity of the selected methyl silicone oil: 500 centipoise, specific surface area of hydrophobic silica: 170m 2 / g, the proportion of hydrophobic silica in the mass of methyl silicone oil is 0.5%, and the two are mixed and stirred and heated to 130°C, with a rotation speed of 400-500rpm, and stirred for 2 hours.

[0038] All other raw materials used in the examples are commercially available.

Embodiment 1

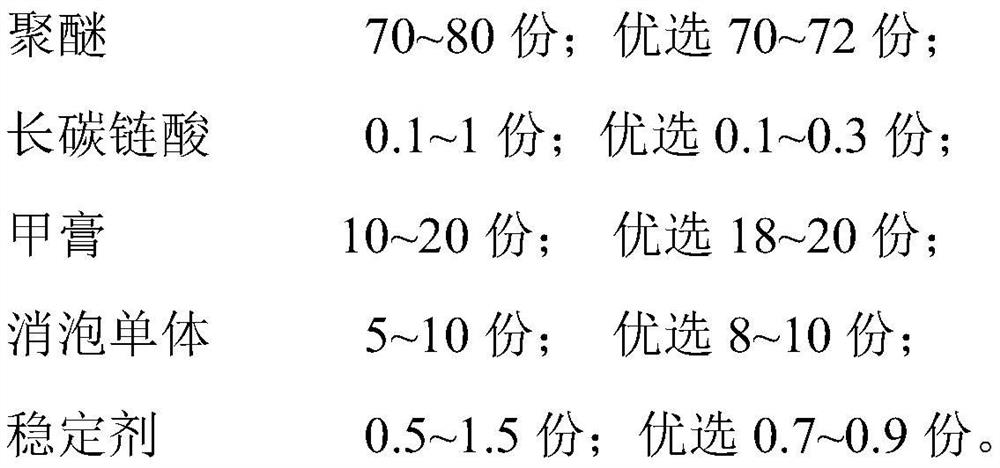

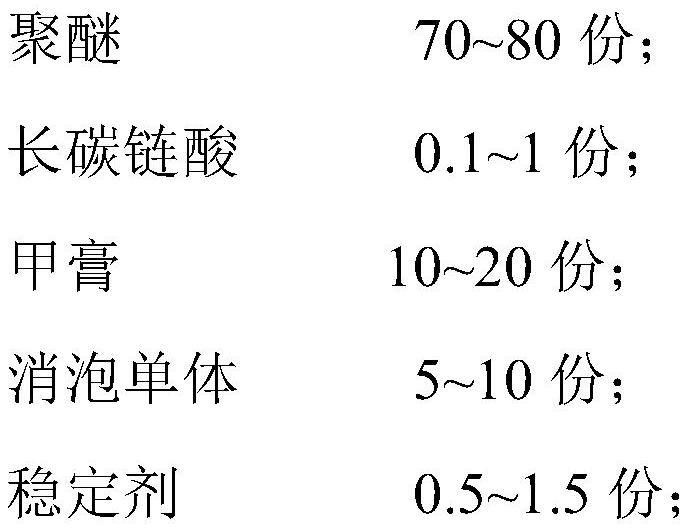

[0040] The preparation process of the defoamer is as follows.

[0041] Based on 100 parts by weight, 70 parts of polyether (L61), 0.1 part of high-grade stearic acid, react at 130°C for 2 hours, add 20 parts of nail cream, react at 130°C for 2 hours, add tributyl phosphate 9 parts, under the condition of 70°C, react for 1 hour, then add 0.9 parts of special tackifier for white oil, and react for 1 hour to obtain defoamer 1.

Embodiment 2

[0043] The preparation process of the defoamer is as follows.

[0044] Based on 100 parts by weight, 71 parts of polyether (L61), 0.2 parts of high-grade stearic acid, react at 130°C for 2 hours, add 18 parts of nail cream, react at 130°C for 2 hours, add tributyl phosphate 10 parts, under the condition of 70°C, react for 1 hour, then add 0.8 parts of special tackifier for white oil, and react for 1 hour to obtain defoamer 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com