Cleaning agent for pcb dry film developing tank and its preparation method and application

A dry film and tank cleaning technology, used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of pungent odor and unsatisfactory removal effect, and achieve good removal effect and good removal. rate, the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

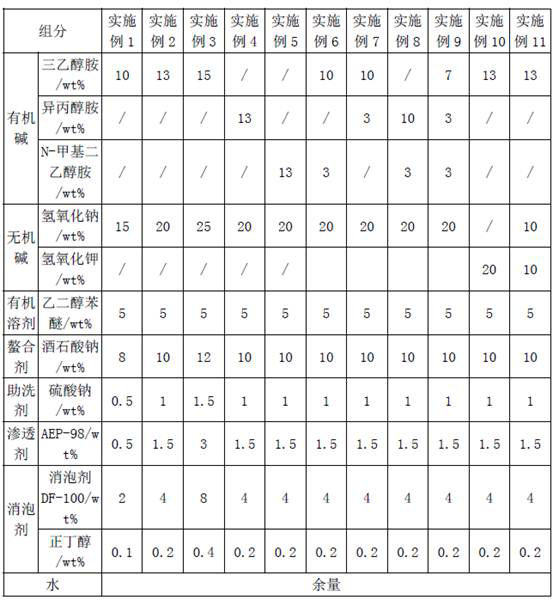

Embodiment 1-11

[0051] Embodiments 1-11 all relate to a kind of cleaning agent for PCB dry film developing tank. In terms of mass percentage content, the raw material composition of each embodiment is as shown in Table 1:

[0052] Table 1.

[0053]

[0054] Preparation scheme: weigh each component according to the ratio in Table 1 and mix them evenly.

[0055] The method for cleaning the PCB dry film developing tank by using the cleaning agent of the embodiment:

[0056] A. Tank preparation method: Each 1L tank solution contains 700-900ml of clear water and 100-300ml of cleaning agent for PCB dry film developing tank;

[0057] B. Bath control and maintenance

[0058] Tank cleaning agent concentration 10-30%

[0059] Temperature 45±3℃

[0060] Time 2-4h (depending on the amount of sediment and the cleanliness of the developing tank)

[0061] Timing of tank cleaning Intermittent boards for 1-2 weeks, if continuous boards are 30,000-40,000 (ft 2 )

[0062] C. Cleaning steps

[0063] 1...

Embodiment 12-16

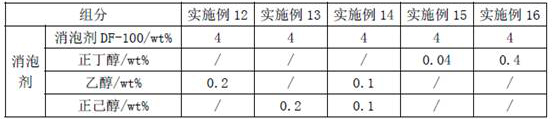

[0070] Embodiment 12-16 is all based on embodiment 2, and the difference with embodiment 2 is only: the composition of defoamer is different, specifically as shown in table 2,

[0071] Table 2.

[0072]

Embodiment 17-23

[0074] Embodiment 17-23 is all based on embodiment 2, and the difference with embodiment 2 is only: the type of organic solvent selected and consumption are different, specifically as shown in table 3,

[0075] table 3.

[0076]

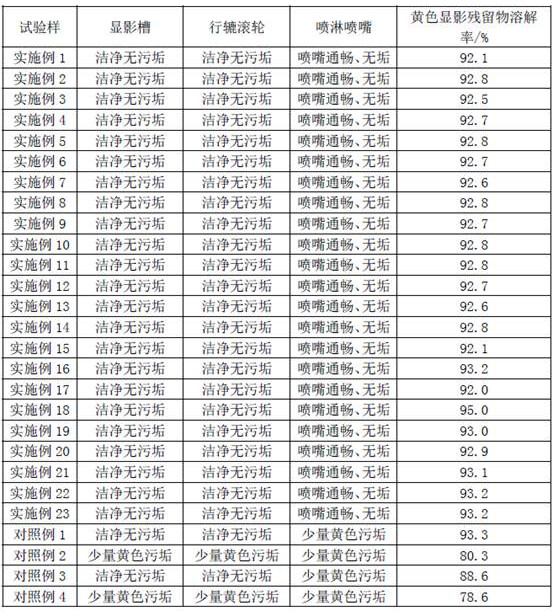

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com